Catalog excerpts

Crushing, disaggregating and separating materials TRANSFORMING

Open the catalog to page 1

TRANSFORMING MATERIALS INTO VALUE The company BHS-Sonthofen, headquartered in Sonthofen, Germany, is an owner-operated group of companies in the field of machine and plant engineering. We offer technical solutions in the field of mechanical process engineering, with a focus on mixing, crushing, recycling and filtration. With over 300 employees and a number of subsidiaries, BHS-Sonthofen has a global presence. Over 100 years of experience in crushing technology We built our first crushers for the aggregates industry over 100 years ago. In addition to targeted crushing, this market...

Open the catalog to page 3

BHS Rotorshredder The BHS Rotorshredder crushes, untangles and disaggregates materials. The crushing tools exert an intense stress on the input material through a combination of impact, punch and shear forces. This results in selective size reduction with the following special features: » Particle sizes are reduced in a targeted manner » Composite materials are separated » Hard and brittle materials undergo intense size reduction » Metals are separated and cleaned » Entangled materials are liberated

Open the catalog to page 4

Simple tools The BHS Rotorshredder uses several rotating hammers flexibly attached to a vertical shaft one above the other. The tools are of a very simple and sturdy design. They do not need to be readjusted or sharpened. Rotorshredder of type 2018 during construction of an E-Scrap recycling plant. The BHS Rotorshredder is designed to disaggregate a broad range of input materials. The intensity and selectivity in processing the input material can be influenced and optimized by means of various machine parameters. The flexibility to be able to cope with changing requirements in the future...

Open the catalog to page 5

Functional description Separation of harmful materials The patented BHS Rotorshredder consists of a cylindrical working chamber with a high-speed vertical shaft. Mounted one above the other on the shaft are pairs of overhung crushing tools. The tools are aligned horizontally and stabilized by centrifugal force. The flexible suspension of the tools on the shaft also serves the purpose of overload protection. The Rotorshredder can optionally be equipped with a flywheel for energy storage. The EU directive for E-Scrap recycling requires that certain components containing harmful substances are...

Open the catalog to page 6

PROCESS STEPS 7 www.bhs-sonthofen.com Example of the crushing process with a refrigerator in the Rotorshredder The crushing ratio and the intensity of stress on the material can be variably adjusted via the speed, and the configuration of the tools and grid. Three machine sizes are available to accommodate various requirements, especially in terms of throughput and input material size. 2. During operation, the hammers are positioned horizontally and stabilized by centrifugal force. 3. The feed is crushed intensively when it reaches the impact chamber. 4. fter just a few seconds the...

Open the catalog to page 7

GRID SEGMENTS FOR MATERIAL DISCHARGE 8 Patented slotted grid A distinctive feature of the Rotorshredder is the patented slotted grid in the large, double-walled doors. The interior of each door consists of grid segments with slots through which the crushed material automatically leaves the working chamber once it has reached the required particle size. Different types of grid segments can be used depending on the input material and requirement. Grid configuration with a large aperture at the bottom, e.g. for the separation of tangled input material. Grid configuration with small apertures...

Open the catalog to page 8

RECYCLING PLANTS 9 www.bhs-sonthofen.com Expertise in plant engineering We design and implement complete recycling plants or plant components for treating recyclable materials for a wide variety of applications. Our experienced specialists are at your service to determine the best possible processes for your requirements. We will be happy to help you by performing tests with your materials at our technical center in Sonthofen. You obtain a future-proof solution with a high throughput, low operating costs and final products in line with market requirements. Numerous references testify to our...

Open the catalog to page 9

Construction and assembly of a complete BHS recycling plant in France. The E-Scrap plant is equipped with a BHS Rotorshredder of type RS 2018. The Rotorshredder is enclosed for disaggregation of E-Scrap in the first recycling stage. The second major component of an E-Scrap recycling plant can be a BHS rotor impact mill of type RPMV 1113 for fully mechanized treatment of the 0-20 mm fine fraction in the second stage

Open the catalog to page 10

Treatment plant for E-Scrap in Romania. The E-Scrap plant in Romania is centered on a Rotorshredder of type RS 2018.

Open the catalog to page 11

INPUT MATERIAL Shredder light fraction Aluminum scrap

Open the catalog to page 12

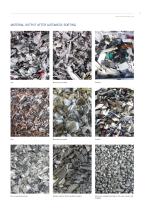

MATERIAL OUTPUT AFTER AUTOMATIC SORTING Non-ferrous metals Non-ferrous metals Pre-crushed aluminum Rubber fraction (from window profiles) Aluminum shaped into balls in the rotor impact mill (RPMV)

Open the catalog to page 13

Tests give certainty We operate an all-weather, industrial-sized treatment plant on our premises in Sonthofen. All our crushing machines are installed in this facility. The crushed material can be separated into different categories using a sieve or overbelt magnet. Samples can be analyzed in further detail. We can perform treatment tests at our center using input material from prospective customers. A variety of machine parameters can be tested. A box feeder is available for large material quantities. Even large input appliances such as heavy washing machines can be processed. All test...

Open the catalog to page 14

Performance data Type D Not suitable for crushing solid parts of high strength. The maximum input size is equivalent to about two thirds of the feed opening. 2) Different data may apply depending on the feed hopper that is used. 3) Weight for standard design including feed and discharge hoppers. All specifications apply to the standard design. Technical data for customized designs may differ from the specified data. All technical data may change due to development.Subject to modification without notice.

Open the catalog to page 15All BHS Sonthofen Process Technology catalogs and technical brochures

-

BFR Rubber Belt Filter

12 Pages

-

RPF Rotary Pressure Filter

16 Pages

-

BF Indexing Belt Filter

16 Pages

-

CF Candle Filter

16 Pages

-

LCS Liquid Clarification Systems

24 Pages

-

Pressure plate filter (PF)

12 Pages

-

Rotary pressure filter

16 Pages

-

Indexing belt filter

16 Pages

-

PF

12 Pages

Archived catalogs

-

DMX Dry Powder Batch Mixer

20 Pages

-

Mixing & Crushing

32 Pages

-

NGU Universal Shredder

12 Pages

-

LFK Twin-Shaft Continuous Mixer

12 Pages

-

DKX Twin-Shaft Batch Mixer

20 Pages

-

NGV SpeedCut Granulator

12 Pages

-

RPM & RPMF Rotor Impact Mill

9 Pages

-

VR Rotary Shear

12 Pages

-

VSR Pre-Shredder

12 Pages

-

RPMV & RPMX Rotor impact mill

16 Pages

-

RBG Biogrinder

12 Pages

-

DKXC Combimix System

8 Pages

-

DKXK Twin-shaft batch mixer

2 Pages

-

RPMV

12 Pages

-

RPM

12 Pages

-

PB & PM

12 Pages

-

MONOMIX & TWINMIX

12 Pages

-

Biogrinder

12 Pages

-

VSI Rotor Centrifugal Crusher

16 Pages

-

Twin-shaft batch mixer

20 Pages