Catalog excerpts

TRANSFORMING MATERIALS INTO VALUE

Open the catalog to page 1

The Company BHS-Sonthofen is an owner-operated group of companies specialized in machinery and plant engineering. The group is headquartered in Sonthofen, Germany. BHS provides technical solutions for mechanical process engineering with its focus on mixing, crushing, recycling and filtration technologies. With more than 300 employees and several subsidiaries, BHSSonthofen maintains a global presence. Experience We have been manufacturing crushers and mills for over 100 years. About 50 years ago, we specialized in impact crushing. The primary focus of our technical development and...

Open the catalog to page 2

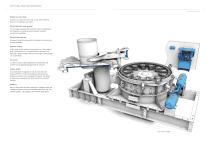

ROTOR IMPACT MILL 4 BHS Rotor Impact Mill Superior Machine Technology Production of Quality Sand The BHS Rotor Impact Mill is a high-performance crusher with a vertical shaft. The rotor impact mill enables you to achieve a high reduction ratio and excellent particle shape. The mill is suitable for crushing all low to moderately abrasive minerals and is therefore used predominantly in the production of sand for the concrete, asphalt and dry mortar industries. Operational unit Unique crushing principle The machine and drive train are assembled onto a base frame as a unit that is ready for...

Open the catalog to page 3

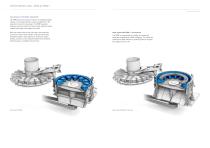

ROTOR IMPACT MILL (RPM & RPMF) 6 Two Versions of the Rotor Impact Mill The RPM is the rotor impact mill used in the building materials industry. The machine has been a proven reliable tool in the production of sand for many years. The RPMF pulverizer produces even finer fractions, and the output material contains a significantly higher percentage of fine sand. BHS rotor impact mills are not only used in the production of sand for the dry mortar industry. They have also proved themselves useful in the production of surfaces for sports facilities, as well as in the milling of fertilizers from...

Open the catalog to page 4

Functional Description Rotor Impact Mill RPM Rotor Impact Mill RPMF – the pulverizer Replaceable crushing tools The input material is fed into the machine from above at the center. When it impacts the rotor, the material is accelerated towards the outside through centrifugal forces; there, the horses oe-shaped hammers hit it and throw it against the h anvil ring. Here, in the milling gap, it is crushed as a result of the impact and shearing forces. The material leaves the rotor through the gap and falls down through two outlet chutes. The pulverizer uses the same crushing principle as the...

Open the catalog to page 5

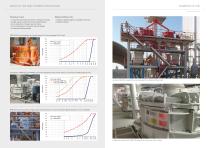

AREAS OF USE AND POSSIBLE APPLICATIONS Milling of fertilizers from: » as concrete and mortar sand for the construction industry » as high-quality crushed sand for the asphalt industry » for the production of ready-mixed dry mortar » for the manufacture of surfaces for sports facilities » for fireproof building materials » limestone, dolomite, gypsum, anhydrite, burnt lime » synthetic fertilizers RPM 1113 for the production of concrete sand (0–2 mm) from gravel (16–32 mm) 100% 90% 80% Input material Final product Sieve fraction Comparison of RPM 1513 and RPMF 1516 for the production of dry...

Open the catalog to page 6

Reinforced cover lining In order to increase the service life, a cover with reinforced lining can be selected as an option. Electro-hydraulic cover opening For even faster opening of the machine cover for maintenance and inspection, an optional electro-hydraulic actuation mechanism is available. Electrical terminal box If required, all electrical wiring can be bundled in a terminal box for easy installation. Intensive cooling In the event of high ambient temperatures or if the material to be processed is hot, a supplementary lubrication unit featuring a larger storage volume and stronger...

Open the catalog to page 7

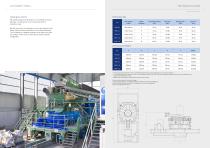

CUSTOMER TRIALS TECHNISCHE DATEN 15 Testing gives certainty We operate a large-scale test plant on our Sonthofen business premises. It comprises all of our crushing machines in production scale. We offer to perform crushing tests on your input material at this facility. Various machine parameters can be tested intensively. This is followed by a detailed evaluation of the data and a grain-size analysis, which serves as the basis for optimal machine configuration. Performance data 1) The throughput rate depends on the circumferential speed of the rotor and the grading curve of the input...

Open the catalog to page 8

CRUSHING TECHNOLOGY RECYCLING TECHNOLOGY FILTRATION TECHNOLOGY 04.2016_801000237_EN, © 2016 BHS-Sonthofen GmbH – All rights reserved. MIXING TECHNOLOGY

Open the catalog to page 9All BHS Sonthofen Process Technology catalogs and technical brochures

-

BFR Rubber Belt Filter

12 Pages

-

RPF Rotary Pressure Filter

16 Pages

-

BF Indexing Belt Filter

16 Pages

-

CF Candle Filter

16 Pages

-

LCS Liquid Clarification Systems

24 Pages

-

Pressure plate filter (PF)

12 Pages

-

Rotary pressure filter

16 Pages

-

Indexing belt filter

16 Pages

-

PF

12 Pages

Archived catalogs

-

DMX Dry Powder Batch Mixer

20 Pages

-

Mixing & Crushing

32 Pages

-

NGU Universal Shredder

12 Pages

-

LFK Twin-Shaft Continuous Mixer

12 Pages

-

DKX Twin-Shaft Batch Mixer

20 Pages

-

NGV SpeedCut Granulator

12 Pages

-

RS Rotorshredder

16 Pages

-

VR Rotary Shear

12 Pages

-

VSR Pre-Shredder

12 Pages

-

RPMV & RPMX Rotor impact mill

16 Pages

-

RBG Biogrinder

12 Pages

-

DKXC Combimix System

8 Pages

-

DKXK Twin-shaft batch mixer

2 Pages

-

RPMV

12 Pages

-

RPM

12 Pages

-

PB & PM

12 Pages

-

MONOMIX & TWINMIX

12 Pages

-

Biogrinder

12 Pages

-

VSI Rotor Centrifugal Crusher

16 Pages

-

Twin-shaft batch mixer

20 Pages