Catalog excerpts

The benchmark in mixing and crushing technology TRANSFORMING MATERIALS INTO VALUE

Open the catalog to page 1

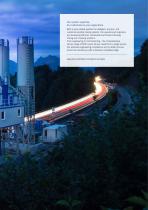

The BHS-Sonthofen head office at the company headquarters in Germany

Open the catalog to page 2

About BHS. BHS-Sonthofen GmbH is an internationally operating company in the field of mechanical process technology. Day in, day out, around 400 employees ensure that we remain a leading provider of intelligent recycling, mixing, crushing and filtration solutions – both at our headquarters in Sonthofen, Germany, and around the world. Our international customers hail from the building materials, recycling, chemical, pharmaceutical, food and feed industries as well as the energy and environmental sectors. At BHS, customers can get everything from a single source: from individual machines...

Open the catalog to page 3

TRANSFORMING MATERIALS INTO VALUE A pioneer and expert in mixing and crushing technology with a tradition reaching back over 130 years. The Mixing Technology division produces batch and continuous mixers and offers the full range of process technology services for mixing applications. The twin-shaft batch mixer, which is considered a global benchmark in the concrete industry, is a key product. In the construction industry the mixers first and foremost are used to produce transport, precast, highperformance and hydro dam concrete, asphalt or concrete paving blocks. BHS mixers are also highly...

Open the catalog to page 4

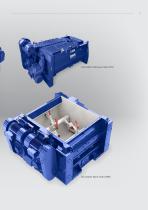

BHS mixers Batch and continuous mixer Twin-shaft batch mixer (DKX) Single-shaft continuous mixer (MFKG)

Open the catalog to page 6

Twin-shaft continuous mixer (LFK) Dry powder batch mixer (DMX)

Open the catalog to page 7

BHS crushers Vertical and horizontal impact crushers Rotor centrifugal crusher (RSMX)

Open the catalog to page 8

Impact crusher & impact mill (PB & PM) Rotor impact mill (RPM & RPMF)

Open the catalog to page 9

Turnkey TWINMIX mixing plant for the production of special concrete (UHPC). It operates with two twin-shaft batch mixers of type DKX.

Open the catalog to page 10

Our system expertise. As customized as your application. BHS is your reliable partner for intelligent, process- and customer-oriented mixing systems. Our experienced engineers are developing efficient, sustainable and forward-thinking mixing and crushing solutions. From engineering to commissioning – the comprehensive service range of BHS covers all your needs from a single source. Our extensive engineering competence and in-depth process know-how provide you with a decisive competitive edge.

Open the catalog to page 11

TWIN-SHAFT BATCH MIXER (DKX) 12

Open the catalog to page 12

Twin-shaft batch mixer (DKX) Twin-shaft mixing technology is suitable for all formulas and offers a wide range of benefits. The mixing procedure has a significant effect on the quality of the mixture produced and the economic efficiency of the production process. » elivers a high level of mixture homogeneity in a D short time » Intensive relative movements throughout the mixture Ready-mixed concrete, precast concrete, high-performance concrete, hydro dam concrete, asphalt, sand-lime bricks, concrete paving blocks, landfill construction materials, backfilling and overburden, clay-and-rock...

Open the catalog to page 13

DRY POWDER BATCH MIXER (DMX) 14 Dual flaps closed Dual flaps open

Open the catalog to page 14

Dry powder batch mixer (DMX) The dry powder batch mixers of the DMX series are specially adapted to the needs of building material manufacturers. The special spiral-blade mixing mechanism with guided material transport alongside both shafts and the highly turbulent mixing zone in the region where the mixing tools overlap ensures intense three-dimensional mixing, even at low rotational speeds. This makes it possible to gently blend in delicate or very light components. Applications Dry mortar, cement mixtures, lime, gypsum, refractory mixes, etc. » Superior twin-shaft mixing technology »...

Open the catalog to page 15

TWIN-SHAFT CONTINUOUS MIXER (LFK) 16 Twin-shaft continuous mixer (LFK) for coarse material Twin-shaft continuous mixer (LFKR) for fine material

Open the catalog to page 16

Twin-shaft continuous mixer (LFK) The BHS twin-shaft continuous mixer is an efficient, reliable solution for continuous mixing processes, especially when handling coarser grain content. Two trough designs – square and round – are available to address different requirements. When mixing coarse materials, a square trough has proven most suitable. The natural material bed offers optimum wear protection. The round trough design is used for fine materials or when products are changed frequently to avoid material carry-over. BHS also offers complete continuous mixing plants including...

Open the catalog to page 17

SINGLE-SHAFT CONTINUOUS MIXER (MFKG) 18 Continuous mixing plant for moisturizing waste materials Continuous mixing plant for moisturizing fly ash

Open the catalog to page 18

Single-shaft continuous mixer (MFKG) The BHS single-shaft continuous mixer is a continuous mixing system which was developed for the intensive mixing of fine materials. Dry and moist, pasty as well as suspension-like mixtures can be produced continuously with the single-shaft continuous mixer. The special shape and arrangement of the mixing tools ensures an intensive mixing process. What sets the BHS single-shaft continuous mixer apart is the self-cleaning, flexible rubber trough, which prevents build ups on the inner trough wall. Liquids are added through nozzles in the inlet area, which...

Open the catalog to page 19

COMBIMIX SYSTEM (DKXC) 20 Combimix system with bottom discharge Combimix system with overflow

Open the catalog to page 20

Combimix System (DKXC) The patented Combimix system transforms the twin-shaft batch mixer (DKX) into a mixer that operates continuously according to the proven three-dimensional mixing principle. This results in a more intense mixing effect and a significantly longer average retention time compared with conventional continuous mixers. The material is extracted at the same rate as the input material is fed into the system. Applications Quality concrete for highway and airport construction, environmental and waste disposal tasks, clay-and-rock mixtures » Continuous mixing process »...

Open the catalog to page 21

CONCRETE MIXING SYSTEMS (MONOMIX & TWINMIX) 22

Open the catalog to page 22

Concrete Mixing Systems (MONOMIX & TWINMIX) The highly mobile BHS concrete mixing plants stand up to adverse ambient conditions, frequent changes of location and permanent operation at maximum load in the harshest of construction conditions. Both the MONOMIX variant with one mixer and the TWINMIX as a dual plant are thus an investment that offers value stability and high availability. At the heart of every plant is the BHS twin-shaft batch mixer that has proven its worth thousands of times over. The system is suitable for rapid relocation within 1.5 days. The fully electrically and...

Open the catalog to page 23All BHS Sonthofen Process Technology catalogs and technical brochures

-

BFR Rubber Belt Filter

12 Pages

-

RPF Rotary Pressure Filter

16 Pages

-

BF Indexing Belt Filter

16 Pages

-

CF Candle Filter

16 Pages

-

LCS Liquid Clarification Systems

24 Pages

-

Pressure plate filter (PF)

12 Pages

-

Rotary pressure filter

16 Pages

-

Indexing belt filter

16 Pages

-

PF

12 Pages

Archived catalogs

-

DMX Dry Powder Batch Mixer

20 Pages

-

NGU Universal Shredder

12 Pages

-

LFK Twin-Shaft Continuous Mixer

12 Pages

-

DKX Twin-Shaft Batch Mixer

20 Pages

-

NGV SpeedCut Granulator

12 Pages

-

RS Rotorshredder

16 Pages

-

RPM & RPMF Rotor Impact Mill

9 Pages

-

VR Rotary Shear

12 Pages

-

VSR Pre-Shredder

12 Pages

-

RPMV & RPMX Rotor impact mill

16 Pages

-

RBG Biogrinder

12 Pages

-

DKXC Combimix System

8 Pages

-

DKXK Twin-shaft batch mixer

2 Pages

-

RPMV

12 Pages

-

RPM

12 Pages

-

PB & PM

12 Pages

-

MONOMIX & TWINMIX

12 Pages

-

Biogrinder

12 Pages

-

VSI Rotor Centrifugal Crusher

16 Pages

-

Twin-shaft batch mixer

20 Pages