Catalog excerpts

Intensive mixing of fine materials TRANSFORMING MATERIALS INTO VALUE

Open the catalog to page 1

TRANSFORMING MATERIALS INTO VALUE The company BHS-Sonthofen, headquartered in Sonthofen, Germany, is an owner-operated group of companies in the field of machine and plant engineering. We offer technical solutions in the field of mechanical process engineering, with a focus on mixing, crushing, recycling and filtration. With over 300 employees and a number of subsidiaries, BHS-Sonthofen has a global presence. Over 125 years of experience in mixing technology BHS-Sonthofen invented the first twin-shaft batch mixer back in 1888 and has been systematically upgrading the design ever since....

Open the catalog to page 3

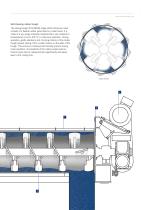

SINGLE-SHAFT CONTINUOUS MIXER 4 BHS single-shaft continuous mixer The BHS single-shaft continuous mixer is a continuous mixing system that has been developed for the mixing of fine materials. The single-shaft continuous mixer can be used for the continuous production of dry or moist recipes or suspension type mixtures. The special shape and arrangement of the mixing tools create an intensive mixing action. MFKG 0520 single-shaft continuous mixer A unique selling point of the BHS single-shaft continuous mixer is the self-cleaning, flexible rubber trough that prevents caking on the inner wall...

Open the catalog to page 4

Consistently high mixture quality The design of the mixer inlet, the shape and arrangement of the mixing tools, and the selection of the appropriate speed ensure a consistent mixture quality. The high speeds create turbulent relative movements in the mixture throughout the entire volume of the mixer trough. This results in consistent, homogeneous mixing results can be achieved in a very short time. Furthermore, undesired agglomerations can be reliably disintegrated by means of shear forces. Self-cleaning rubber trough One unique selling point of the single-shaft continuous mixer (MFKG) is...

Open the catalog to page 5

MIXING CONCEPT AND MACHINE DESIGN 6 Optimized mixing process In the BHS single-shaft continuous mixer, the different formula ingredients are forcefully accelerated by the fast-rotating mixing tools. The centrifugal force results in a ring of mixture with turbulent swirl formation along the inner wall of the mixer. The mixing tools generate extreme relative movements of the mixture. This results in optimal mixing and consistently high levels of homogeneity. It is also possible to process materials that are otherwise very difficult to mix or that are mixed in very different proportions....

Open the catalog to page 6

Self-cleaning rubber trough The mixing trough of the MFKG single-shaft continuous mixer consists of a flexible rubber jacket fixed in a steel frame. It is made of a very tough industrial material that is also resistant to temperatures of up to 150 °C in continuous operation. During operation, gentle vibrations and churning motions of the rubber trough prevent caking of the curable mixture on the walls of the trough. This ensures a continual self-cleaning process during mixer operation. The elasticity of the rubber jacket reduces friction losses due to caking and also significantly decreases...

Open the catalog to page 7

Production of suspensions and pastes Coal dust suspensions, overburden, mortar suspensions, ash suspensions, etc. Sludge and soil conditioning Sewage sludge, chalk slurry, ferric arsenate sludge, paper sludge, etc. Moistening of dust Fly ash from waste incineration, fly ash from power plants, foundry dust, limestone powder, etc.

Open the catalog to page 8

SOLUTIONS FOR CONTINUOUS DOSING AND WEIGHING 9 www.bhs-sonthofen.com In a continuous mixer, the continuous dosing and weighing of the mixture are of decisive importance for achieving optimal mixing results for the required formula. Gravimetric dosing and weighing Volumetric dosing and weighing Bulk material flowmeter Screw conveyor Non-contact ultrasound flow measurement Rotary valve Double weighing Vibrating chute Belt weigher

Open the catalog to page 9

Automatic central lubrication During operation, the central lubrication continuously supplies the inner shaft seals with barrier grease, thereby reducing maintenance requirements. Water control system Liquids are added in proportion to the solid input material via a fully automatic dosing station. This consists of a flowmeter, regulating valve, dosing valve, pressure regulator and pressure switch. Hydraulic system for cover opening For quicker and easier opening of the cover for maintenance and inspection, an optional hydraulic actuation mechanism is available for the cover. Auxiliary...

Open the catalog to page 10

ATEX design The mixer and its peripheral equipment can be configured for specific ATEX zones. BHS-Sonthofen meets all the relevant requirements and is ATEX certified. Stainless steel variant For special requirements, such as corrosive mixtures, the single-shaft continuous mixer can be made of stainless steel.

Open the catalog to page 11

PLANT EXAMPLES Source: Putzmeister Solid Pumps Continuous mixing plant with an MFKG 0728 for producing a suspension of fly ash and bottom ash. The mixture is then pumped into a landfill site. MFKG 0520 at the heart of a plant for moistening fine materials, such as ash and dust, from silos.

Open the catalog to page 12

Plant for moistening dry ash from a power plant with an MFKG 0728. Moist ash can also be deposited on the discharge belt. Turnkey mixing plant with an MFKG 0520 for continuous moistening of waste materials. These powdery fine materials, such as fly ash from incinerating plants, dust or fine sand, are deposited in landfills after moistening.

Open the catalog to page 13

Tests give certainty BHS offers customers the opportunity to run mixing tests with their own specific materials at its technical center in Sonthofen. Furthermore, laboratory mixers can also be loaned for operation directly at the customer’s plant. All test results are recorded, documented and analyzed according to mutually agreed criteria. We would be pleased to advise and assist you. BHS technical center in Sonthofen for customer-specific testing

Open the catalog to page 14

Performance data (standard designs) Type D The bulk density of the specific input materials must be specified for selection of the suitable mixer size. 2) The throughput parameters (max. particle size, bulk density, etc.) of the specific input materials must be specified for selection of the suitable drive power rating. 3) Drive via bevel gear motor. 4) Dimension from center of mixer inlet to center of mixer outlet. 5) Weight for standard design without accessories. All specifications apply to the standard design. Technical data for customized designs may differ from the specified data. All...

Open the catalog to page 15All BHS Sonthofen Process Technology catalogs and technical brochures

-

BFR Rubber Belt Filter

12 Pages

-

RPF Rotary Pressure Filter

16 Pages

-

BF Indexing Belt Filter

16 Pages

-

CF Candle Filter

16 Pages

-

LCS Liquid Clarification Systems

24 Pages

-

Pressure plate filter (PF)

12 Pages

-

Rotary pressure filter

16 Pages

-

Indexing belt filter

16 Pages

-

PF

12 Pages

Archived catalogs

-

DMX Dry Powder Batch Mixer

20 Pages

-

Mixing & Crushing

32 Pages

-

NGU Universal Shredder

12 Pages

-

LFK Twin-Shaft Continuous Mixer

12 Pages

-

DKX Twin-Shaft Batch Mixer

20 Pages

-

NGV SpeedCut Granulator

12 Pages

-

RS Rotorshredder

16 Pages

-

RPM & RPMF Rotor Impact Mill

9 Pages

-

VR Rotary Shear

12 Pages

-

VSR Pre-Shredder

12 Pages

-

RPMV & RPMX Rotor impact mill

16 Pages

-

RBG Biogrinder

12 Pages

-

DKXC Combimix System

8 Pages

-

DKXK Twin-shaft batch mixer

2 Pages

-

RPMV

12 Pages

-

RPM

12 Pages

-

PB & PM

12 Pages

-

MONOMIX & TWINMIX

12 Pages

-

Biogrinder

12 Pages

-

VSI Rotor Centrifugal Crusher

16 Pages

-

Twin-shaft batch mixer

20 Pages