Catalog excerpts

Clarification & concentration TRANSFORMING MATERIALS INTO VALUE

Open the catalog to page 1

TRANSFORMING MATERIALS INTO VALUE The company BHS-Sonthofen, headquartered in Sonthofen, Germany, is an owner-operated group of companies in the field of machine and plant engineering. We offer technical solutions in the field of mechanical process engineering, with a focus on mixing, crushing, recycling and filtration. With over 300 employees and a number of subsidiaries, BHS-Sonthofen has a global presence. Cake filtration BHS has specialized in cake filtration for more than 50 years. We supply a broad range of pressure and vacuum filters for both batch and continuous operation. We have...

Open the catalog to page 3

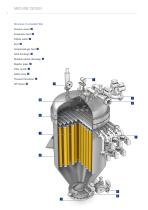

BHS Candle Filter (CF) The Candle Filter is a batch-operated filter. The candle-shaped filter elements are arranged vertically inside a pressure vessel. Typical process steps are filtration, washing, drying and discharging. All these steps are carried out under pressure. The Candle Filter is used for clarifying liquids with a low solids content. It is a compact unit, operates fully automatically and allows high throughput rates, dry cake discharge and a wide range of cake treatment options. Complete Candle Filter plant of type CF 24-113 with 76 m² filter area

Open the catalog to page 4

High process versatility Alternative materials A variety of options are available for treating the filter cake, enabling the individual process requirements to be met. The cake can be washed or reslurried in one or more stages. Air, nitrogen or other gases can be passed through the filter cake to achieve a greater degree of dewatering. If required, precoat filtration by means of filter aids is possible. To suit the individual application, we manufacture in various grades of stainless steel and alloys or coated designs and plastics. Depending on the requirement, ground and polished surfaces...

Open the catalog to page 5

Structure of a Candle Filter Pressure vessel Suspension feed Filtrate outlet Vent Compressed gas feed Solid discharge Residual volume discharge Register pipes Filter candle Safety valve Pressure transducer CIP device

Open the catalog to page 6

Structure of a candle Central pipe Designed as a dip pipe, the central pipe allows complete residual discharge of the filtrate. Connection of the candle to the register The candle is connected to the register by means of a thread at the end of the central pipe. Support grid for filter medium The support grid for the filter cloth is a perforated body and allows a high filtrate throughput. Evenly spaced welded rods The evenly spaced welded rods cause a wave-like configuration of the filter medium and corresponding build-up of the filter cake. Stable, reliable cake formation is the result....

Open the catalog to page 7

CANDLE FILTER PLANTS 8 BHS manufactures Candle Filter plants for diverse applications. These are based on a range of standardized modules for plants from 1 m² to 50 m² filter area. BHS also makes individually engineered Candle Filter plants to customer specifications. The BHS Candle Filter plant consists of the following four main components: » Candle filter » Piping with fittings and measuring instruments » Steel structure » PLC controls The skid can be supplemented and expanded with further accessories. Process solution Besides the machinery itself, BHS also offers complete process...

Open the catalog to page 8

ACCESSORIES & VERSIONS 9 www.bhs-sonthofen.com Heel filtration device Tube sheet design for slurry discharge The heel filtration device enables the residual volume to be processed on completion of the filtration cycle by means of an internally filtering candle at the vessel cone. This ensures complete heel filtration with a minimum of compressed gas. In the case of slurry discharge, the candles are mounted on a tube sheet that separates the filtrate and suspension chambers. The filter cake is discharged by backflush with filtrate. Under specific conditions, the tube sheet design represents...

Open the catalog to page 9

Sweetening amine process, Turkmenistan Processing of amine for natural gas desulfurization. The BHS system comprises two units. Each unit contains a Candle Filter of type C 24-113 with a 76 m² filter area, a precoating station, two activated carbon absorbers and a control filter. Processing an amine solution, Canada Two-stage processing of amine desufurization of exhaust gas from a power station. In the first stage, the solution is clarified using two parallel Candle Filters of type CF 18-37, each with a 19 m² filter area, and a joint body feed system. In the second stage, the concentrated...

Open the catalog to page 10

Cleaning of electrolyte fluid, Germany Cleaning of the electrolyte used in the coating unit of a cold strip mill. The BHS plant consists of three Candle Filters of type CF 21-049, each with a 29.4 m² filter area.

Open the catalog to page 11

Sweetening amine process, USA Cleaning an amine solution used in a gas scrubber unit of a refinery. The BHS plant comprises two Candle Filters of type CF 18-19, each with a 10 m² filter area.

Open the catalog to page 12

Regeneration of grey water, USA Regeneration of grey water in a coal gasification plant. The BHS plant comprises three Candle Filters of type CF 179-66, each with a 66 m² filter area. Filtration of rubbed-off catalyst parts, USA Removing FCC fines from water used for gas scrubbing in a refinery. The BHS plant comprises two Candle Filters of type CF 23-147, each with a 100 m² filter area and a precoating unit.

Open the catalog to page 13

Tests give certainty We perform initial tests with our pocket leaf filters. These tests can be performed quickly and easily at your location or in our well-equipped laboratory in Sonthofen. Basic data can thus be obtained about the filterability of a suspension and the general design of a production filter. For more extensive tests, even spanning several weeks, we can rent out pilot and lab filters for all BHS filter types. Filters made of different materials are also available. If necessary, the filters can be equipped to meet specific customer requirements. These filters can be used to...

Open the catalog to page 14All BHS Sonthofen Process Technology catalogs and technical brochures

-

BFR Rubber Belt Filter

12 Pages

-

RPF Rotary Pressure Filter

16 Pages

-

BF Indexing Belt Filter

16 Pages

-

LCS Liquid Clarification Systems

24 Pages

-

Pressure plate filter (PF)

12 Pages

-

Rotary pressure filter

16 Pages

-

Indexing belt filter

16 Pages

-

PF

12 Pages

Archived catalogs

-

DMX Dry Powder Batch Mixer

20 Pages

-

Mixing & Crushing

32 Pages

-

NGU Universal Shredder

12 Pages

-

LFK Twin-Shaft Continuous Mixer

12 Pages

-

DKX Twin-Shaft Batch Mixer

20 Pages

-

NGV SpeedCut Granulator

12 Pages

-

RS Rotorshredder

16 Pages

-

RPM & RPMF Rotor Impact Mill

9 Pages

-

VR Rotary Shear

12 Pages

-

VSR Pre-Shredder

12 Pages

-

RPMV & RPMX Rotor impact mill

16 Pages

-

RBG Biogrinder

12 Pages

-

DKXC Combimix System

8 Pages

-

DKXK Twin-shaft batch mixer

2 Pages

-

RPMV

12 Pages

-

RPM

12 Pages

-

PB & PM

12 Pages

-

MONOMIX & TWINMIX

12 Pages

-

Biogrinder

12 Pages

-

VSI Rotor Centrifugal Crusher

16 Pages

-

Twin-shaft batch mixer

20 Pages