Catalog excerpts

BGB Engineering Ltd were the first slip ring manufacturer to design a dedicated wind turbine slip ring for development of slip ring solutions for this growing industry. BGB remain at the forefront of turbine technology and work closely with major wind turbine manufacturers such as market leaders, Vestas.

Open the catalog to page 3

Silver provides the best material for reliable signal transfer, and very low signal noise. In most cases, sealed enclosures are used to prevent the ingress of liquids meet customers required IP rating. Power & Signal Slip ring assemblies are used for the transfer of power and data between the slow speed main shaft. BGB can manufacture custom units that combine power slip rings with signal/optical/hydraulic rotary joints. Power channels utilise Phosphor Bronze rings in conjunction with either Copper graphite or Silver graphite brushes. Signal channels make use of silver to silver contacts,...

Open the catalog to page 4

BGB are at the forefront in slip ring design for a dedicated wind turbine slip ring for hub control systems. As leaders in the field BGB are always innovating and improving products to suit customers in the wind turbine Units can be supplied with matched looms complete with quick disconnect/connect systems for ease Pitch Control (Blade BGB units can transfer high integrity digital and analogue signals including tachometers, strain measurement, proximity switches and relay circuits in all harsh environmental conditions (heavy vibrations, high altitude, humidity and sub-zero temperatures)....

Open the catalog to page 5

GENERATOR SLIP RINGS: High Voltage Power Slip BGB provide slip ring and brush holder solutions for varying current and voltage Products can be supplied with a rating Standards. These products can be supplied solely or as part of a packaged High power units are primarily used for power take off from the wind turbine Helical grooved slip rings are used in applications that have higher rotational speeds. The benefits of • Better commutation between the working faces • more uniform current distribution between brushes BGB can develop slip ring designs or repair solutions for existing platforms...

Open the catalog to page 6

FIBRE OPTIC ROTARY JOINTS (FORJ's) COMBINED WITH CONVENTIONAL SLIP RING The Optilinc range of FORJs devices are adaptable for the most Made to withstand the harsh environments of offshore wind farms, Optilinc has exceptional durability, protecting the unit from dust and water ingress to IP67. The Optilinc FORJ has been fully tried and tested in leading wind turbine manufacturers development Power Slip Ring Incorporating FORJ's As well as stand alone media converters and WDMs, BGB can build all Optilinc products into bespoke slip ring solutions incorporating connections to suit each...

Open the catalog to page 7

BESPOKE SLIP RING ASSEMBLIES: Bespoke Assemblies total rotary solutions developed to customer specification or retrofit current solutions. , The design office use the latest I 3DCAD technology and work with world leading wind turbine design engineers to produce innovative solutions and bespoke assemblies. Testing can include; dynamic electrical tests, IR EMC, HALT, Thermal shock, Vibration and Surge tests. Dynamic/static balancing is also standard practice. BGB have been fully accredited and certified as a Schenck specialist contract balancing service provider (both static and dynamic)....

Open the catalog to page 8

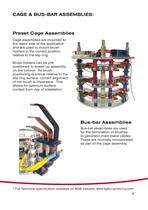

CAGE & BUS-BAR ASSEMBLIES: Preset Cage Assemblies Cage assemblies are mounted to the stator side of the application and are used to mount brush holders in the correct position relative to the slip ring. positioned to speed up assembly positioning is critical relative to the slip ring surface, correct alignment of the brush is imperative. This allows for optimum surface contact from day of installation. Bus-bar Assemblies Bus-bar assemblies are used to generator main stator cables. These are normally incorporated as part of the cage assembly. * Full Technical specification available on BGB...

Open the catalog to page 9

3KW-20KW SERIES SLIP RINGS: Small Wind Turbine Slip Ring Units manufactured post top slip rings to accommodate the yawing of a turbine to many of the 3Kw-20Kw wind turbine These units are primarily used in remote locations, farms and small businesses to independently generate electricity in the absence of mains grid As with the larger slip ring assemblies, units can be designed customer requirements. Slip rings can be made with protective covers to protect from extreme elements up to an IP rating Full Technical specification available on BGB website: www.bgbengineering.com

Open the catalog to page 10

GENERATOR BRUSH HOLDERS: Generator Brush Holders BGB offer a wide range of standard brush holders to suit all applications Single or multi brush designs are available for generators and high power applications. Brush holders can be custom designed to suit specific customer BGB use constant force springs and non ferrous materials where appropriate. Various forms of wear detection are also available. Brush holders provide housing for the static side of the rotational electrical contact. Generator brush holders are primarily used in high rotational speed / high current density * Full Technical...

Open the catalog to page 11

BRUSH HOLDERS: Custom Brush Holders BGB work closely with global customers to develop more efficient, cost effective brush holder solutions. Benefits include longer brush life, reduction in service time, improved cooling and minimal brush contact face area by using the optimum brush compound. Paratec is a BGB designed parallel action brush system that provides high contact integrity and system stability for both signal and power The non-metallic body ensures suitability for operation in corrosive environments (such as marine) whilst captive screws improve serviceability. BGB now fit this...

Open the catalog to page 12

BRUSH HOLDERS: Standard Brushes & Holders The range of standard brush holders are very adaptable and lend themselves to both fast and slow moving applications. Standard construction is brass with copper foil or braid connections requested). Double spring versions and brushes are available where The range varies from simple callipers and cartridges to advanced fixed box holders with constant force springs BGB have been in the wind industry since 1991 and have sold many thousands of brush holder units worldwide to major wind turbine OEMs. BGB brush holders are uniquely easily replaced when...

Open the catalog to page 13All BGB Innovation catalogs and technical brochures

-

Optilinc

1 Pages

-

120 Amp Brush Holder

2 Pages

-

PARATEC Brush Holders

1 Pages

-

Optilinc

12 Pages