Website:

BETE

Website:

BETE

Catalog excerpts

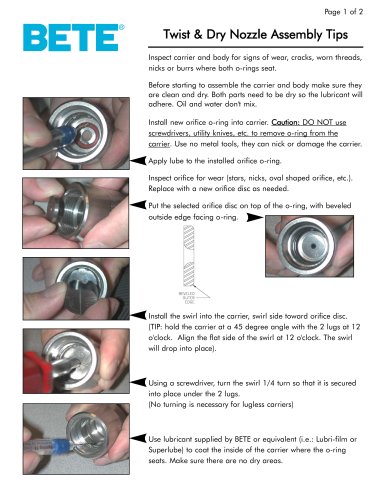

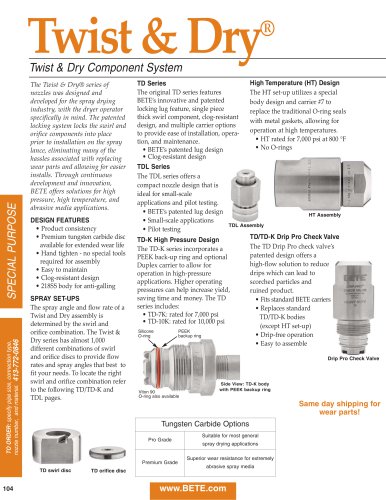

Inspect carrier and body for signs of wear, cracks, worn threads,nicks or burrs where both o-rings seat.Before starting to assemble the carrier and body make sure theyare clean and dry. Both parts need to be dry so the lubricant will adhere. Oil and water don't mix.Install new orifice o-ring into carrier. Caution: DO NO T use screwdrivers, utility knives, etc. to remove o -ring from the carrier . Use no metal tools, they can nick or damage the carrier.Apply lube to the installed orifice o-ring. Inspect orifice for wear (stars, nicks, oval shaped orifice, etc.).Replace with a new orifice disc as needed.Put the selected orifice disc on top of the o-ring, with beveledoutside edge facing o-ring. Install the swirl into the carrier, swirl side toward orifice disc.(TIP: hold the carrier at a 45 degree angle with the 2 lugs at 12 o'clock. Align the flat side of the swirl at 12 o'clock. The swirl will drop into place).Using a screwdriver, turn the swirl 1/4 turn so that it is securedinto place under the 2 lugs. (No turning is necessary for lugless carriers)Use lubricant supplied by BETE or equivalent (i.e.: Lubri-film orSuperlube) to coat the inside of the carrier where the o-ring seats. Make sure there are no dry areas. >

Open the catalog to page 1

Page 2 of 2 Apply lube to the body threads and o-ring groove generously.Lubricant needs to be in the o-ring groove so the o-ring will not stick to the body when the carrier is tightened down or removed. This step is only for the high pressure Twist & Dry (TD -K K) nozzle . Install the backup ring into the body o-ring groove. The backup ring has a split bias cut which allows it to expand to fit over the body o-ring groove. Once the backup ring is over the body o- ring groove, it can be released and it will snap into place. Make sure the backup ring is positioned in the o-ring groove and...

Open the catalog to page 2All BETE catalogs and technical brochures

-

WL metric

1 Pages

-

PJ metric

1 Pages

-

NF

1 Pages

-

SpiralAir

2 Pages

-

TW metric

1 Pages

-

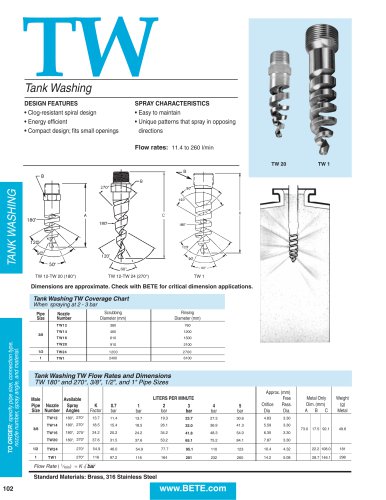

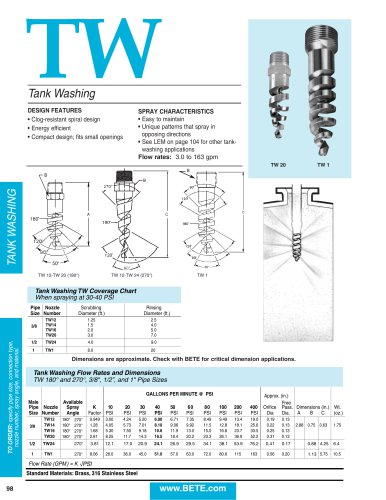

TW

1 Pages

-

AFF metric

1 Pages

-

TF10-170

1 Pages

-

TF24

1 Pages

-

TF FM Approved

1 Pages

-

TF metric

1 Pages

-

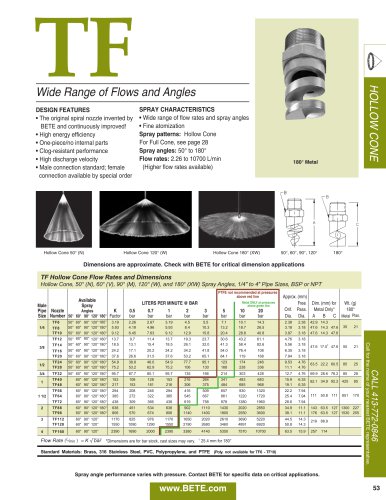

TF

1 Pages

-

TF

1 Pages

-

MaxiPass®

2 Pages

-

HydroClaw®

2 Pages

-

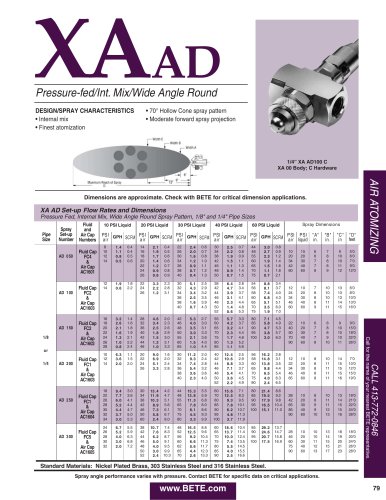

XAAD

1 Pages

-

ST

1 Pages

-

XA Components & Options

1 Pages

-

Engineering Information

9 Pages

-

Custom In-House Fabrications

2 Pages

-

BETE Spray Nozzle Catalog

134 Pages

-

Line Card

2 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

BETE Metric Catalog

132 Pages

-

NFH

1 Pages

-

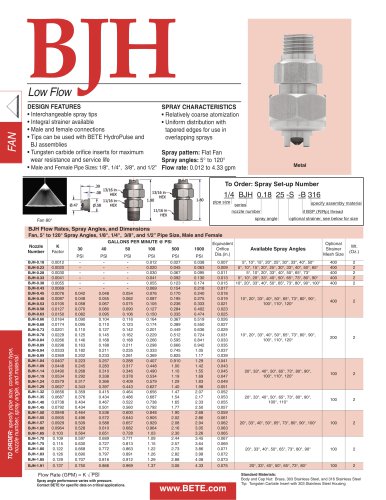

BJH

1 Pages

-

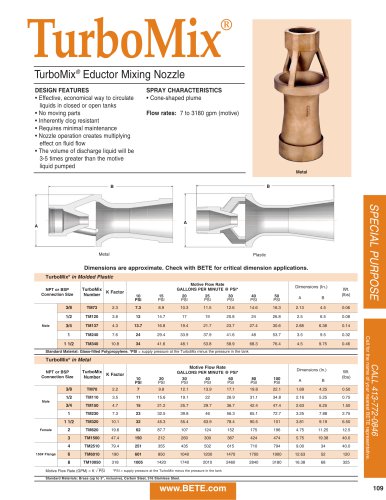

TurboMix

1 Pages

-

Twist & Dry

5 Pages

-

TF29

1 Pages

-

N fire protection

1 Pages

-

AFF

1 Pages

-

LEM

1 Pages

-

CLUMP

1 Pages

-

HydroWhirl Orbitor

2 Pages

-

HydroWhirl ® Poseidon

1 Pages

-

HydroWhirl S

1 Pages

-

SpiralAir

2 Pages

-

SAM

2 Pages

-

XA Accessories

4 Pages

-

XA

7 Pages

-

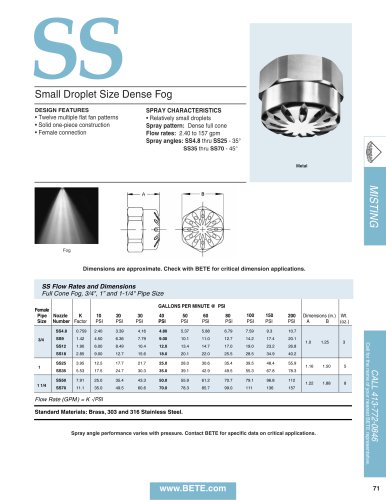

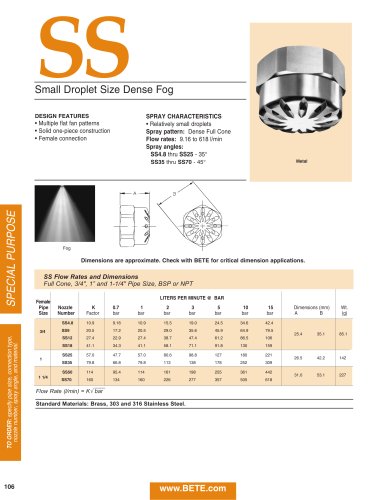

SS

1 Pages

-

UltiMist

1 Pages

-

L

1 Pages

-

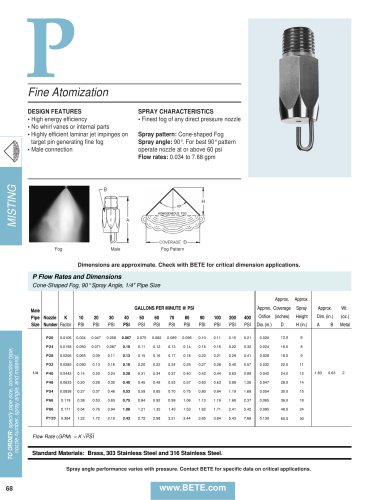

p

1 Pages

-

PJ

1 Pages

-

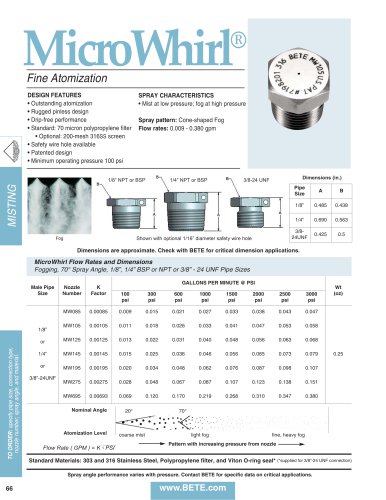

MicroWhirl

1 Pages

-

SPN

1 Pages

-

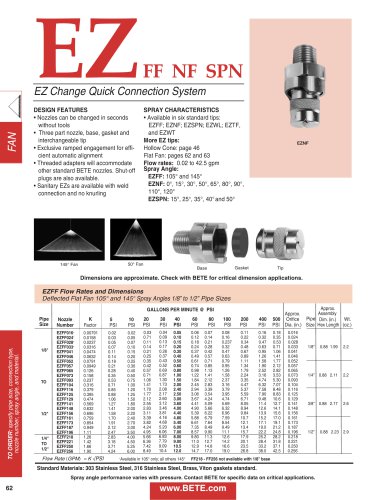

EZ FF NF SPN

2 Pages

-

FF

2 Pages

-

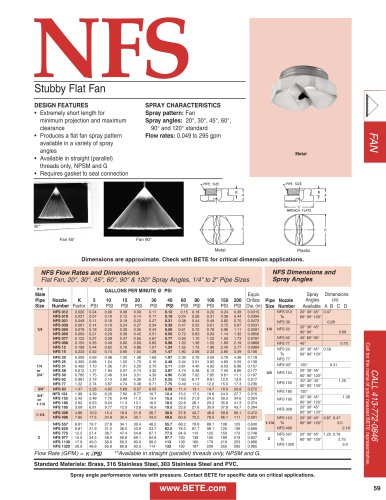

nfs

1 Pages

-

NFD

1 Pages

-

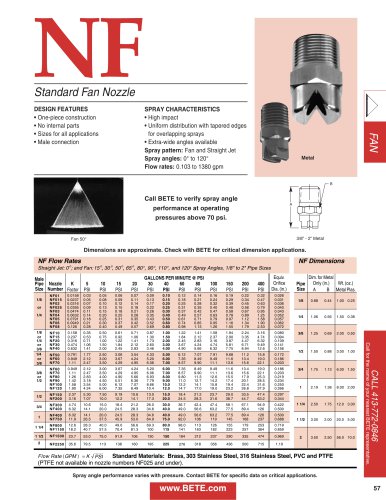

NF

1 Pages

-

NFV

1 Pages

-

HydroPulse

4 Pages

-

BJ

2 Pages

-

Spillback

2 Pages

-

THW

2 Pages

-

NCJ

1 Pages

-

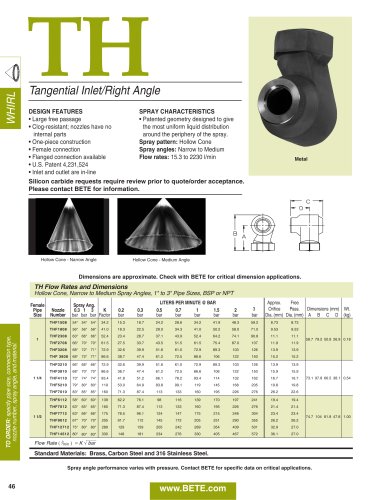

TH

2 Pages

-

WTX

2 Pages

-

WT

2 Pages

-

TC

1 Pages

-

NCFL

1 Pages

-

NCK

1 Pages

-

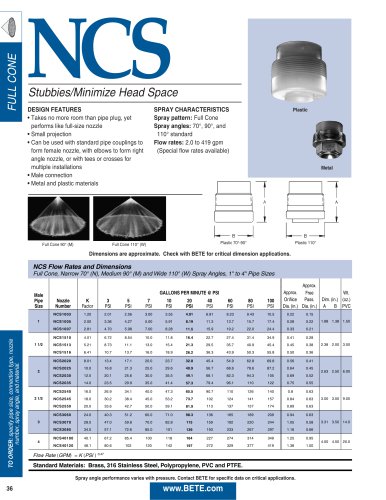

NCS

1 Pages

-

NC

2 Pages

-

SF

3 Pages

-

EZFF

2 Pages

-

WTZ

1 Pages

-

CW

2 Pages

-

WL

1 Pages

-

STXP

1 Pages

-

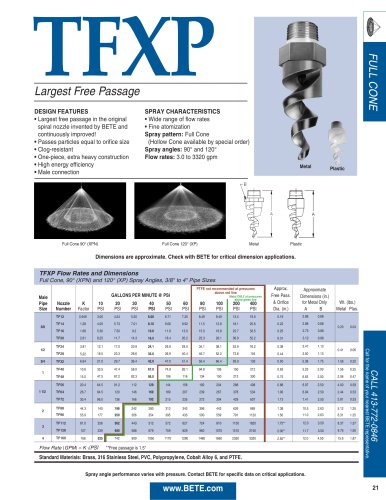

TFXP

1 Pages

-

TF

2 Pages

-

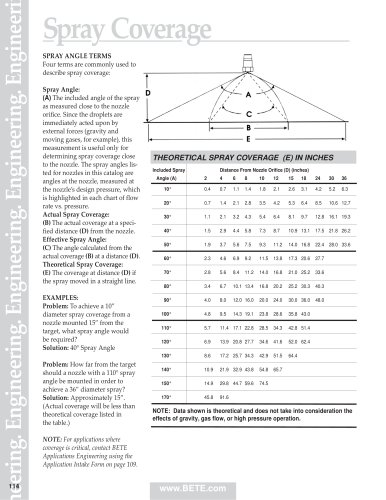

Spray Coverage

1 Pages

-

Bete accessories

1 Pages

-

MATERIALS

1 Pages

-

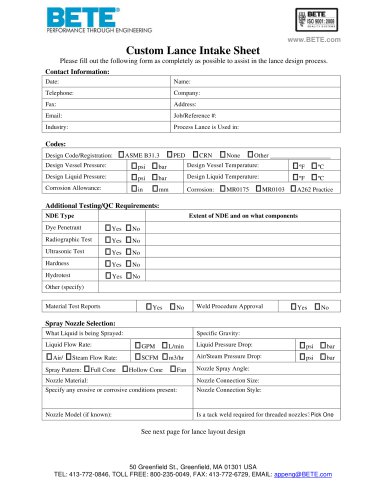

Custom Lance Intake Sheet

2 Pages

-

Pollution Control

8 Pages

-

Food Industry

8 Pages

-

Fire Protection

8 Pages

-

DUR O LOK®

6 Pages

-

Chemical Processing

8 Pages

-

Spray Nozzle Catalogs

127 Pages

-

MaxiPass ® L

1 Pages

-

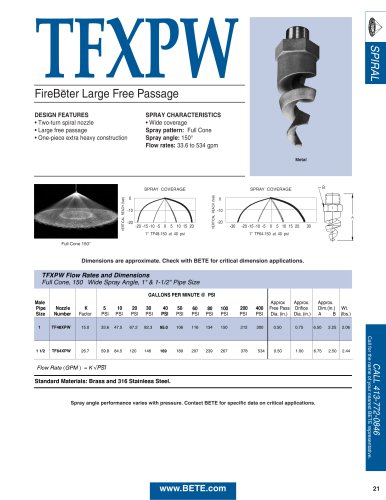

TFXPW

1 Pages

-

N

2 Pages

-

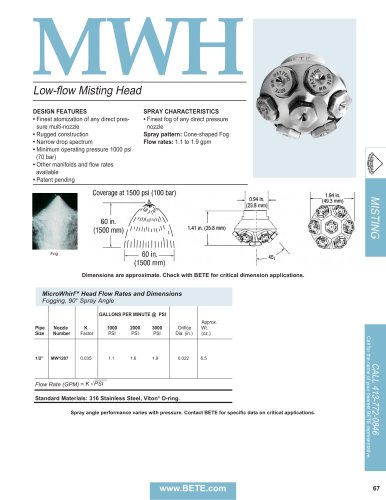

MicroWhirlTM Head (MWH)

1 Pages

-

MaxiPassTM Low Flow (MPL)

1 Pages

-

MaxiPassTM (MP)

2 Pages

-

LP

1 Pages

-

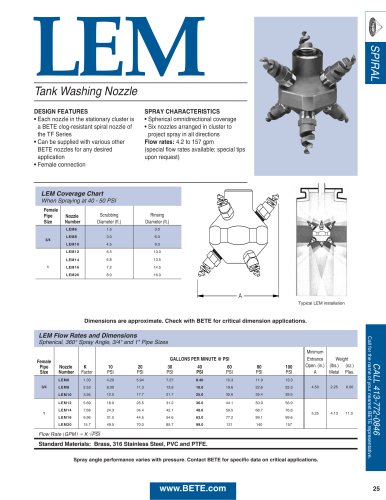

LEM

1 Pages

-

IS

1 Pages

-

FluidBed

1 Pages

-

Spray Drying

11 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

TD/TD-K

4 Pages

-

FINZTM

1 Pages

-

SpiralAirTM

2 Pages

-

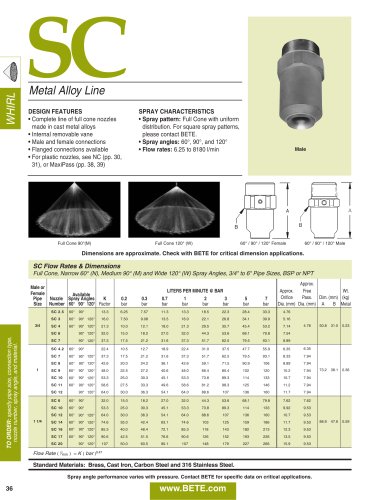

SC

2 Pages

Archived catalogs

-

N Fire Protection

2 Pages

-

TW

1 Pages

-

Spray dry manual

25 Pages