Catalog excerpts

PRAYING SOLUTIONS NOZZLES FOR INDUSTRY, POLLUTION CONTROL, AND FIRE PROTECTION

Open the catalog to page 1

ith thousands of different spray nozzles available in hundreds of different materials, it’s often hard to know where to start. We’ve incorporated a number of unique charts and other aids into this catalog to simplify your selection process. Nozzle Selection Guide There are many ways to select a nozzle. Which way is right for you? Still not sure? Don’t have time to look? Call us. BETE Customer Service Representatives and Applications Engineers will listen to your problem and guide you to the nozzle you need. Let our expertise save you time and keep your process running at peak efficiency....

Open the catalog to page 2

Innovation is a BETE hallmark and we are proud that over 60% of the nozzles we ship have been customized to meet your needs. If you don’t see your nozzle listed, please call BETE. Special flow rates a

Open the catalog to page 3

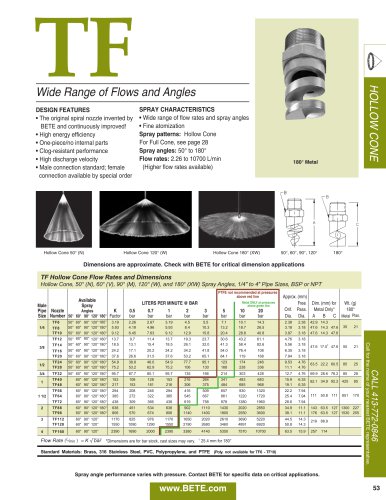

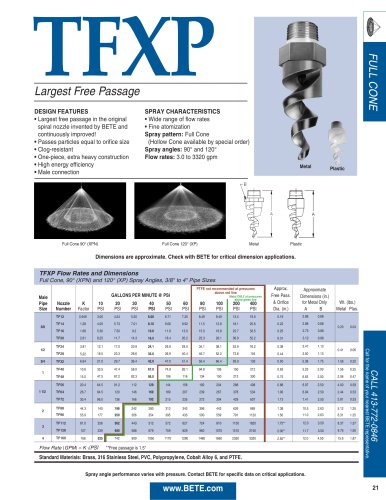

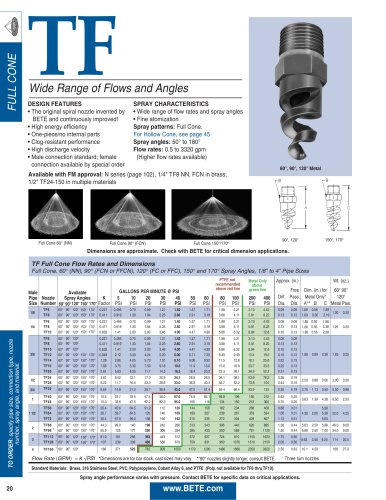

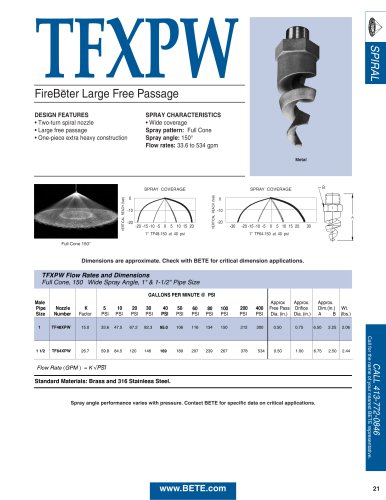

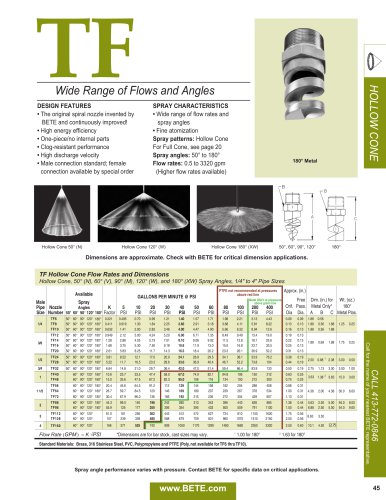

...by SPRAY PATTERN Full Cone Nozzles The most frequently used nozzle type in industry is the full cone nozzle. The spray emits from the nozzle in a conical shape with the liquid dispersed over the interior of the cone. When the spray intersects with a surface, a circle of spray is formed with liquid present throughout. The full cone pattern from a spiral nozzle consists of several concentric hollow cones that combine to produce a full cone effect with a smaller droplet size. TF The standard spiral line, available in a wide range of flows, angles, and materials. 1/8”‑ 4” p. 20 TFXP Same as...

Open the catalog to page 4

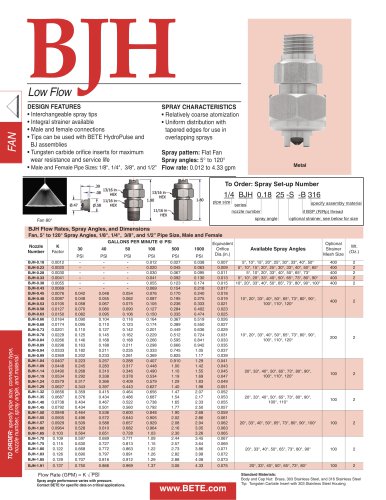

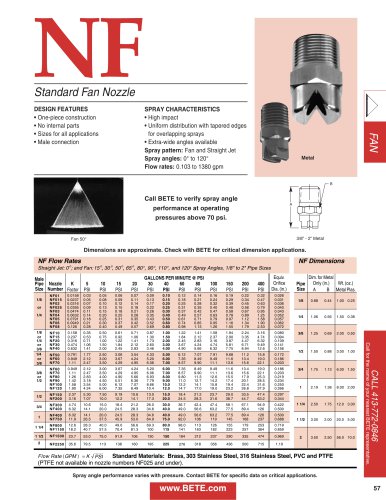

Fan Nozzles These nozzles produce a thin, flat sheet of liquid that expands outward from the nozzle. A thin line of liquid is produced when the spray intersects a surface. As the liquid is concentrated into a smaller net area, the impact force from fan nozzles is greater than from full or hollow cone nozzles. Low flow nozzle with inter‑changeable tips; fan spray. 1/8”‑ 3/8” Fan nozzle with integral strainer option. 1/8” or 1/4” Deflector‑ style; extra‑ wide angle flat fan spray. 1/8”‑ 1” Flat fan nozzle with self‑aligning dovetail connection and interchangeable tips. 1/4”‑ 1 1/4” p. 58...

Open the catalog to page 5

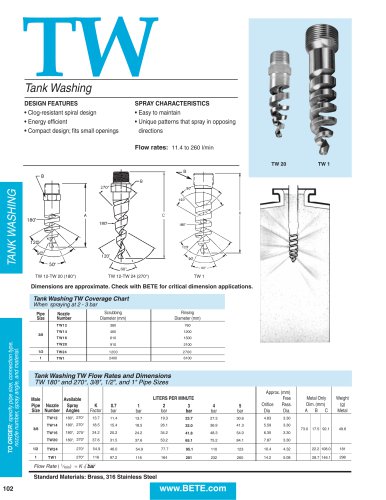

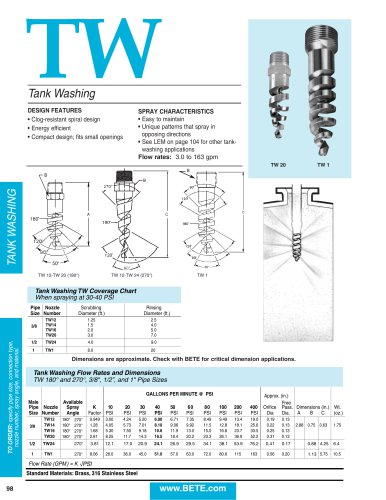

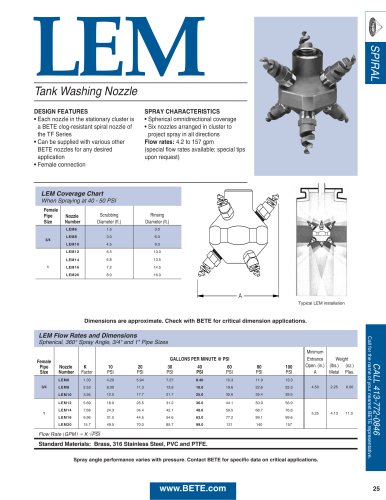

Tank Washing Nozzles These specialized products are customized to the task of cleaning the interior surfaces of tanks. The typical 360° spray pattern covers all internal surfaces while specialized 270° and 180° patterns focus the cleaning fluid on specific surfaces. Models range from basic fixed nozzles to advanced fluid-driven tank cleaning machines. HydroWhirl Poseidon HydroWhirl S High impact rotary tank cleaning machine. 360° and 180° wash patterns. 2 or 4 nozzle configurations Rotating tank washing nozzle in PTFE. Ideal for harsh chemical environments. 1/2”‑ 1‑1/2” p. 96 Slotted,...

Open the catalog to page 6

...by APPLICATION Choosing the correct nozzle for your application from BETE’s 20,000+ products can be daunting. To help, here is a list of some of the more common uses for spray nozzles. Each application is followed by several BETE nozzle series which have been used in this application. The series used most often is listed first. The operating pressures, flow rate, and spray angle ranges are typical for each application. The full operating range for each series is generally broader. If you don't see your application, or need advice making a nozzle selection, please call us at 413‑772‑0846....

Open the catalog to page 7

Clog‑resistant Nozzles Wide free passage to spray lumpy, viscous liquids with less clogging Coating Apply thin coatings (wet or dry) on product moving past nozzles Concrete Curing Humidify concrete to control curing process Cooling: Deluge Process cooling for food, chemical, and industrial processes Cooling: Evaporative Cool hot (+ 300°F) flue gases prior to entering a baghouse or temperature‑ sensitive equipment Cooling: Parts Cool hot parts on conveyors from pre‑treatment ovens Cooling: Pond Cool pond water; heat recovery HydroWhirl Poseidon HydroWhirl Orbitor Rotating and stationary...

Open the catalog to page 8

Remove bark from logs prior to pulping Distribute fluids uniformly onto packing, trickle bed media, and horticultural beds; VOC stripping Drying Remove excess water after washing or rinsing Dust Control: Air‑handling Ducts Suppress stone, coal and other dust in vent ducts; control paint spray carry‑over Dust Control: Area Suppress dust at con‑ veyor transfer points, dump pits, and loading hoppers Etching: Electronics Wash and rinse circuit boards and wafers 0.5-10 psi 0.5-115 gpm used in pairs lumpy liquids p. 110 SpiralAir MicroWhirl 40- 80 psi 0.28-3.42 gpm 90° very fine dust p. 69 40- 80...

Open the catalog to page 9

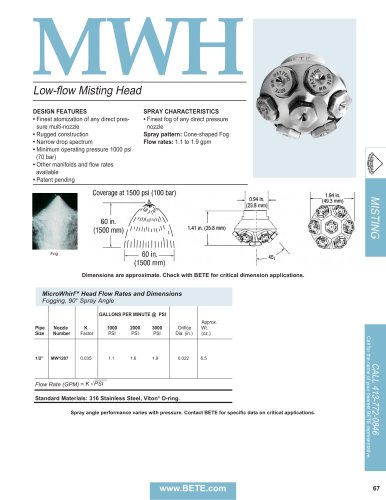

Fire Protection: Fire Protection: Special Protect coal conveyors; fueling and vulcanizing cabinets; warehouses and munitions storage Fire Protection: Water Wall Protect personnel, evacuation muster areas, equipment, and structures from heat radiation Foam Control Control build‑up of foam in aeration and settling basins; mixing vessels and below weirs; and spillways Fog Nozzles Fine atomization misting; movie special effects Food Processing Applying flavorants or colorants Deluge Protect offshore platforms, storage tanks, hazardous loading areas, and equipment bays TFXP 60- 150 psi 52- 300...

Open the catalog to page 10

Moisten paper; mist produce; compost piles of crushed products Mixing Eductors Keep solids suspended by eduction Full Cone Tank Washing Special Purpose MicroWhirl SpiralAir Clean mist eliminators in packed or open tower scrubbers Mist Eliminator Wash Lubricate dies and moulds; roll bite in strip mills 0.5- 10 psi 0.5- 115 gpm used in pairs lumpy liquids p. 110 Hollow Cone Moistening Wetting, humidifying products on conveyor Odor Control Spray odor neutralizing agents Packing Distribute scrubbing liquor in scrubbers or water in humidifiers Pollution Control Distribute slurry in open towers...

Open the catalog to page 11

Pulp Bleaching Quench Evaporatively quench hot gases Roll Cooling Cool rolls in steel strip mills Wall wash bleaching tanks SpiralAir MicroWhirl Scrubbing: Conditioning Inject ammonia or water upstream of electrostatic precipitators; inject odor control additives Scrubbing: Direct Contact Spray water or reagent slurry into open tower; flue gas desulphurization Scrubbing: Dry Inject lime slurry; inject food and chemical prod‑ uct into spray dryer Self Cleaning Nozzles/ Showers Clean webs in paper mills, wash or rinse steel strip or conveyor belts Spray Drying Street Flushing & Cleaning High...

Open the catalog to page 12All BETE catalogs and technical brochures

-

WL metric

1 Pages

-

PJ metric

1 Pages

-

NF

1 Pages

-

TW metric

1 Pages

-

TW

1 Pages

-

AFF metric

1 Pages

-

TF10-170

1 Pages

-

TF24

1 Pages

-

TF FM Approved

1 Pages

-

TF metric

1 Pages

-

MaxiPass®

2 Pages

-

HydroClaw®

2 Pages

-

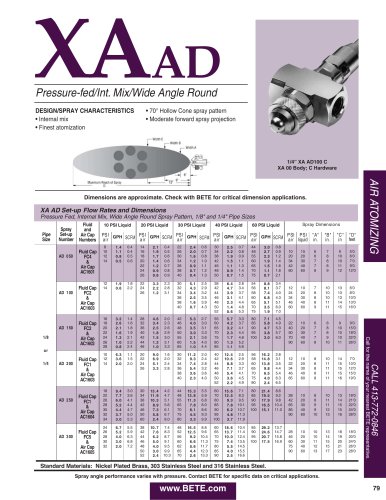

XAAD

1 Pages

-

ST

1 Pages

-

XA Components & Options

1 Pages

-

Engineering Information

9 Pages

-

Custom In-House Fabrications

2 Pages

-

BETE Spray Nozzle Catalog

134 Pages

-

Line Card

2 Pages

-

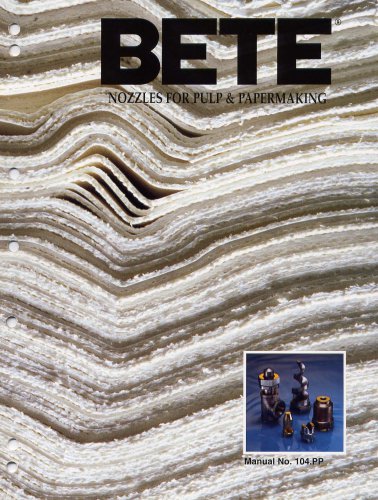

Bottle, Drum & Tank Washing

16 Pages

-

BETE Metric Catalog

132 Pages

-

NFH

1 Pages

-

BJH

1 Pages

-

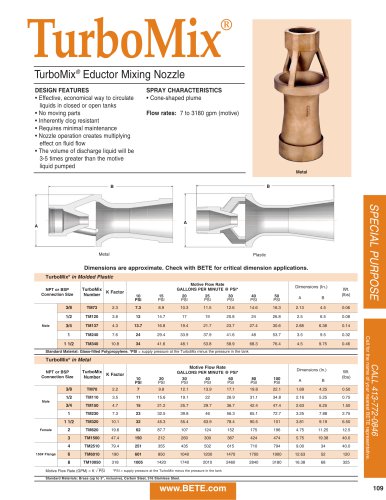

TurboMix

1 Pages

-

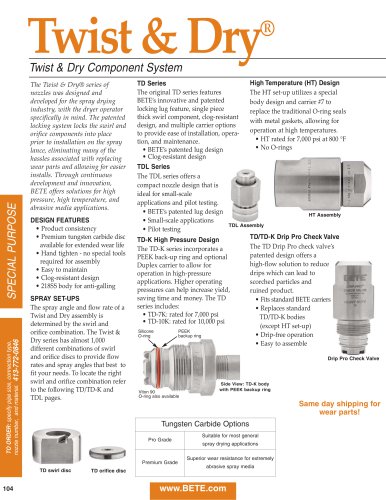

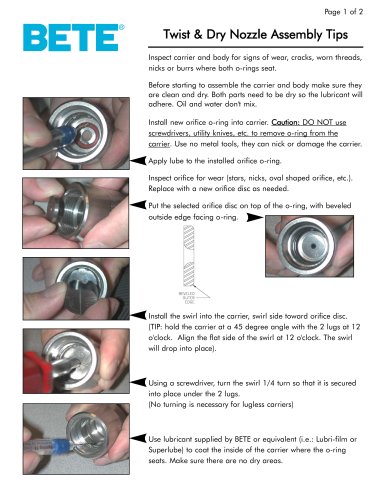

Twist & Dry

5 Pages

-

TF29

1 Pages

-

N fire protection

1 Pages

-

AFF

1 Pages

-

LEM

1 Pages

-

CLUMP

1 Pages

-

HydroWhirl Orbitor

2 Pages

-

HydroWhirl ® Poseidon

1 Pages

-

HydroWhirl S

1 Pages

-

SAM

2 Pages

-

XA Accessories

4 Pages

-

XA

7 Pages

-

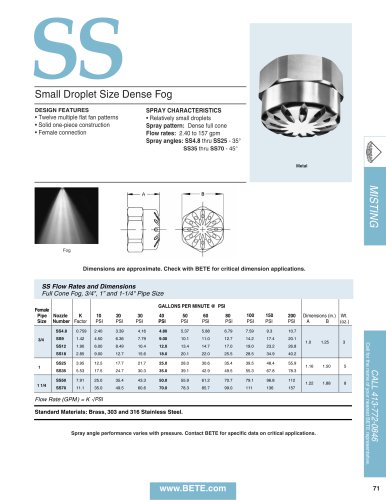

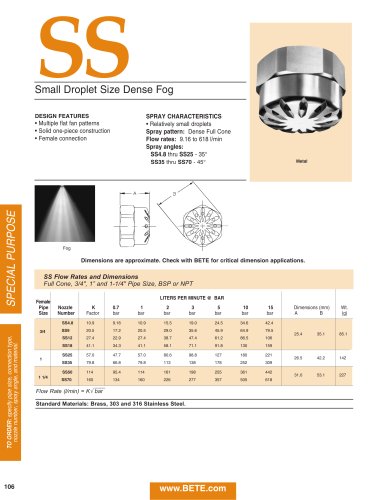

SS

1 Pages

-

UltiMist

1 Pages

-

L

1 Pages

-

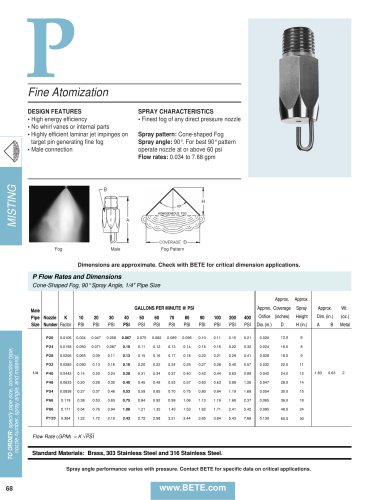

p

1 Pages

-

PJ

1 Pages

-

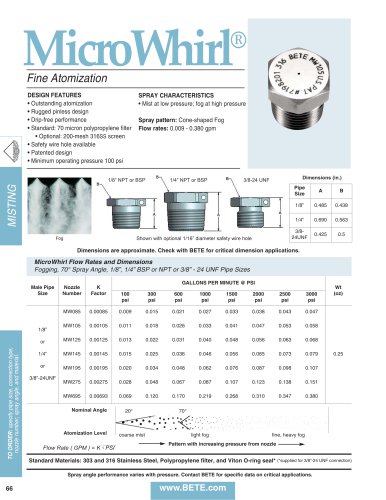

MicroWhirl

1 Pages

-

SPN

1 Pages

-

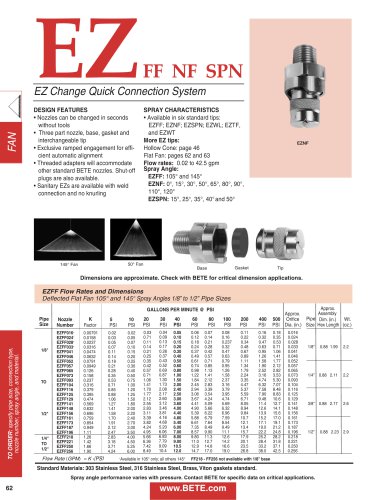

EZ FF NF SPN

2 Pages

-

FF

2 Pages

-

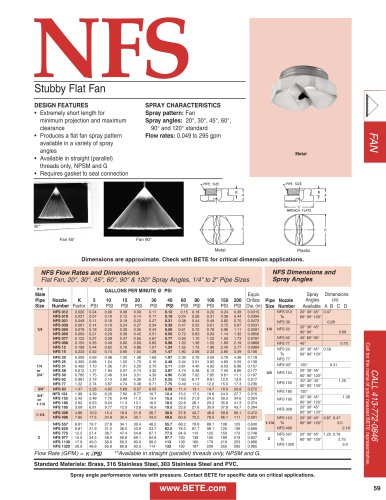

nfs

1 Pages

-

NFD

1 Pages

-

NF

1 Pages

-

NFV

1 Pages

-

HydroPulse

4 Pages

-

BJ

2 Pages

-

Spillback

2 Pages

-

THW

2 Pages

-

NCJ

1 Pages

-

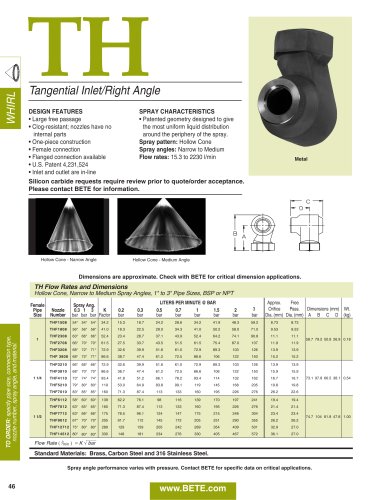

TH

2 Pages

-

WTX

2 Pages

-

WT

2 Pages

-

TC

1 Pages

-

NCFL

1 Pages

-

NCK

1 Pages

-

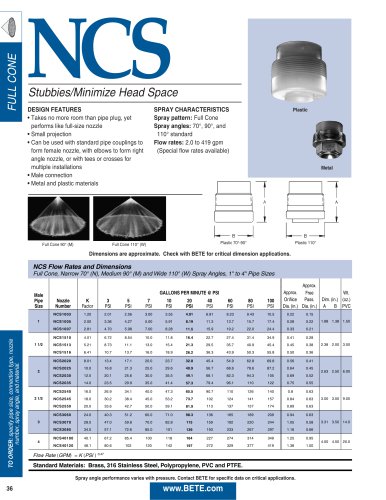

NCS

1 Pages

-

NC

2 Pages

-

SF

3 Pages

-

EZFF

2 Pages

-

WTZ

1 Pages

-

CW

2 Pages

-

WL

1 Pages

-

STXP

1 Pages

-

TFXP

1 Pages

-

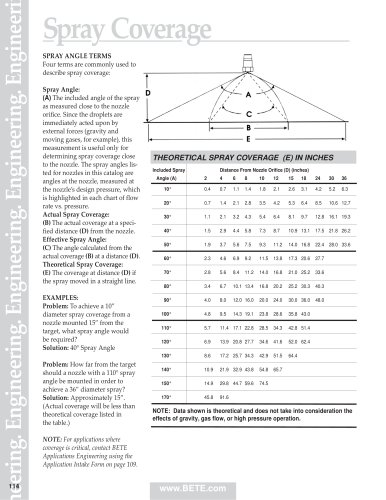

Spray Coverage

1 Pages

-

Bete accessories

1 Pages

-

MATERIALS

1 Pages

-

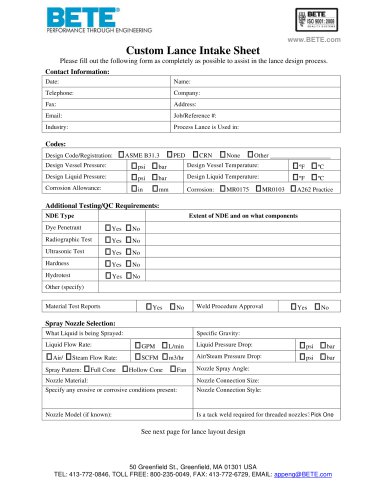

Custom Lance Intake Sheet

2 Pages

-

Pollution Control

8 Pages

-

Food Industry

8 Pages

-

Fire Protection

8 Pages

-

DUR O LOK®

6 Pages

-

Chemical Processing

8 Pages

-

MaxiPass ® L

1 Pages

-

TFXPW

1 Pages

-

N

2 Pages

-

MicroWhirlTM Head (MWH)

1 Pages

-

MaxiPassTM Low Flow (MPL)

1 Pages

-

MaxiPassTM (MP)

2 Pages

-

LP

1 Pages

-

LEM

1 Pages

-

IS

1 Pages

-

FluidBed

1 Pages

-

Spray Drying

11 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

TD/TD-K

4 Pages

-

FINZTM

1 Pages

-

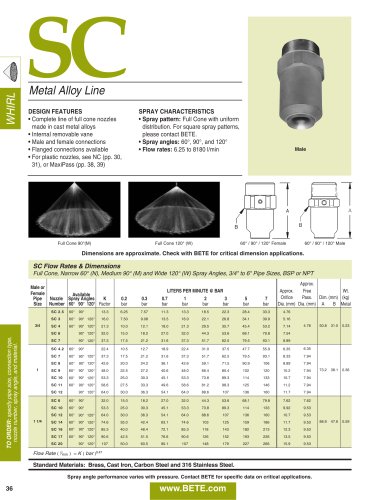

SC

2 Pages

Archived catalogs

-

TF_2021

1 Pages

-

TF

1 Pages

-

SpiralAir

2 Pages

-

N Fire Protection

2 Pages

-

TW

1 Pages

-

SpiralAirTM

2 Pages

-

Spray dry manual

25 Pages