Website:

BETE

Website:

BETE

Catalog excerpts

9 1.0 Introduction 2 1.1 Why dry? 2 1.2 Why Spray Dry? 6.1 Powder Shape 9 6.2 Powder Size 2 1.3 History of spray drying 9 6.3 Size distribution 2 1.4 Spray drying basics 9 6.4 Bulk density 2 1.4.1 Concentration 9 6.5 Factors affecting bulk density 2 1.4.2 Atomization 9 6.6 Agglomeration 2 1.4.3 Droplet-air contact 9-10 2 1.4.4 Droplet drying 3 1.4.5 Separation 7.0 Spray Dry Nozzle Selection 10 3 7.1 Replacing the Delavan SDX 10 7.2 Replacing Other Nozzles 10 7.3 Twist & Dry Software 2.0 Spray Dryer Types 3 10 2.1 Co-current flow 3 2.2 Counter-current flow 3 2.3 Mixed flow 8.0 Spray nozzle...

Open the catalog to page 2

1.4.3 Droplet-air contact The central element of a spray dryer is the spray dry chamber. In the chamber, atomized liquid is brought into contact with hot gas (usually air, at a vacuum), resulting in the evaporation of 95%+ of the water contained in the droplets in a matter of a few seconds. The way in which the spray makes contact with the air in the dryer influences the behavior of the droplet during the drying phase and has a direct bearing on the properties of the dried product. The type of contact between the spray and the air is determined by the position of the atomizer relative to...

Open the catalog to page 3

Open Cycle Co-current Flow Layout Counter-current Flow Dryer > Fig 2.4.1 Fig 2.2.1 3. > dried product 4. > drying chamber 5. > cyclone 6. > wet scrubber 7. > bag filter 8. > electrostatic precipitator Open Cycle Layout > Fig. 2.4.2 1. > drying air Mixed Flow Dryer 2. > feedstock Fig 2.3.1 3. > dried product 5. > cyclone 6. > Alt. A: wet scrubber 7. > Alt. B: bag filter 8. > Alt. C: electrostatic precipitator

Open the catalog to page 5

condensed water discharge > Figure 2.6.1 1. combustion air 2. coolant 3. feedstock 4. fuel 5. condensed waste discharge 6. dried product 7. dryer chamber 8. cyclone 9. indirect heater 10. heat exchanger 11. scrubber/condenser 12. transport cyclone 13. pneumatic transport system >

Open the catalog to page 6

Twist & Dry is capable of handling this entire pressure range. The TD-K should be used for pressures above 3500 PSI and up to 10,000 PSI. See the TD Material Selection Guide for the appropriate TD nozzle setup for your operating conditions. 3.4 Two-fluid nozzles Liquid feedstock and compressed air (or steam) are combined in a two-fluid nozzle. The design utilizes the energy of compressed gas to atomize the liquid. Two-fluid nozzles are able to atomize highly viscous feeds, but they are expensive to operate because of the high cost of compressed air. Two advantages of the two-fluid nozzle...

Open the catalog to page 8

Nozzle Wizard software will calculate an estimated sauter mean diameter for any set of operating conditions. 4.10 Micron The unit of measurement used for particles. One micron equals one millionth of a meter, or 0.0000394 inches. 4.11 BETE Twist & Dry Droplet Size BETE has done extensive droplet size testing on the Twist & Dry in the BETE laboratory, spraying water. The Twist & Dry nozzle is capable of producing sprays with sauter mean diameters ranging from about 30 microns to 120 microns, depending on the pressure and flow rate. The BETE > 4.8 Sauter mean diameter (D32) 4.1 Droplet 4.2...

Open the catalog to page 9

6.5 Factors affecting bulk density 6.4 Bulk density Increasing feed rate increases bulk density if the residual moisture increases 6.3 Size distribution Օ If increasing feed temperature leads to the production of spherical droplets instead of threadsђ, bulk density increases. The size distribution of dried particles is generally narrower than the size distribution of atomized liquid particles. Rotary atomizers produce more uniform particle sizes compared to pressure atomizers. Bulk density is the weight of dried powder per unit volume. This is a critical factor for most spray drying...

Open the catalog to page 10

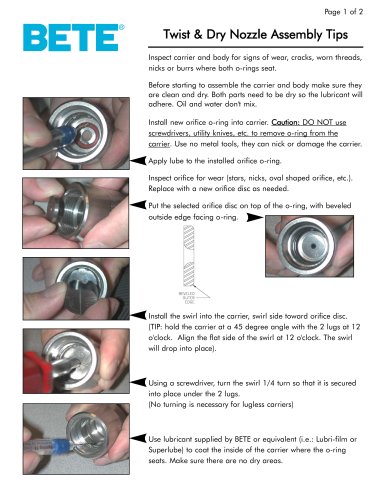

8.5 Body The velocity of feedstock through the internal passages of the body are much lower than the 8.4 Seals Leaking nozzles in a spray dryer can cause serious problems, including ruined product, fires and explosions. For this reason, it is critical to ensure that the nozzles will not leak during operation. Most Twist & Dry nozzles use o-rings as seals. Because of the high operating pressures and high temperatures of the spray dry chamber, BETE recommends that the o-rings be replaced each time that the nozzle is disassembled. BETE recommends the use of a USDA approved lubricant on all...

Open the catalog to page 11

to aid in the removal of swirl units. > velocity through the swirl and orifice and, as a result, wear rates are much lower. The body is attached to the feed pipe either by welding or by tapered pipe threads. For bodies with a threaded connection to the supply pipe, BETE recommends the use of Loctite 272 thread sealant. To apply Loctite 272 thread sealant: Dryer operators usually use a dilute caustic solution (1-2% NaOH) for nozzle cleaning. When drying dairy products such as cheese, whey, and milk, the nozzles must be cleaned immediately following shut down in order to prevent the parts...

Open the catalog to page 12

Soap and detergent products alky-aryl sulphonates detergent enzymes dispersing agents emulsifying agents fatty alcohol sulphate heavy-duty detergents light-duty detergents mono and dipotassium orthophosphate mono and disodium orthophosphate nitrilo tri-acetic acid salts optical brightener phosphates saponine sodium lauryl sulphate 9.3 Detergents, soaps and surface active agents The production of washing powders is one of the most common spray dry applications. Counter- current dryers with nozzle atomization are preferred for high-bulk-density detergents. Open-cycle dryers are most commonly...

Open the catalog to page 13

using rotary atomizers. Mineral and ore products Copper ore Cryolite Iron ore Lead ore Manganese ore Molybdenum ore Nickel ore Platinum ore Silver ore Tungsten ore 9.8 Inorganic chemicals Cement slurries are dried prior to calcining operations in spray dryers using either rotary atomizers or pressure nozzles. Spray drying is well established in the preparation of catalysts. Due to the great variation in catalyst requirements, rotary atomizers, pressure nozzles and two-fluid nozzles are used. Both rotary atomizers and pressure nozzles are used to spray dry sodium silicate (waterglass)....

Open the catalog to page 15All BETE catalogs and technical brochures

-

WL metric

1 Pages

-

PJ metric

1 Pages

-

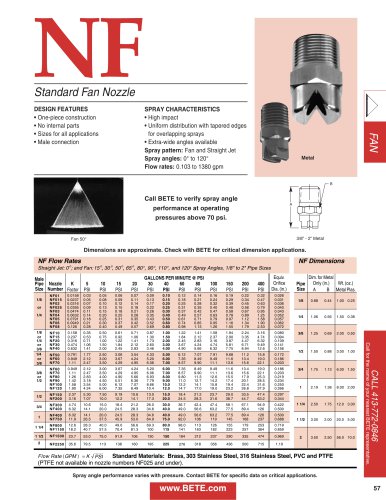

NF

1 Pages

-

SpiralAir

2 Pages

-

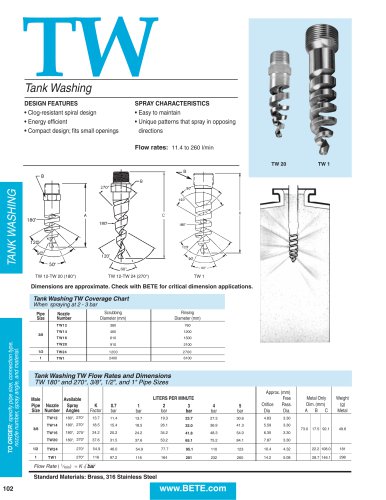

TW metric

1 Pages

-

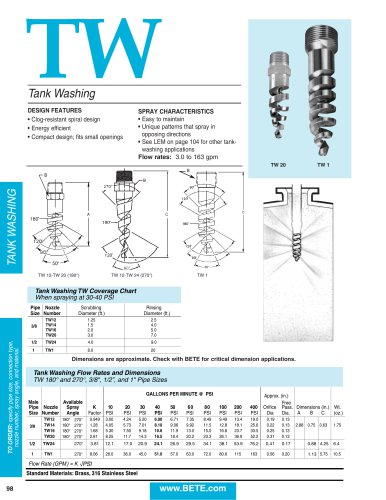

TW

1 Pages

-

AFF metric

1 Pages

-

TF10-170

1 Pages

-

TF24

1 Pages

-

TF FM Approved

1 Pages

-

TF metric

1 Pages

-

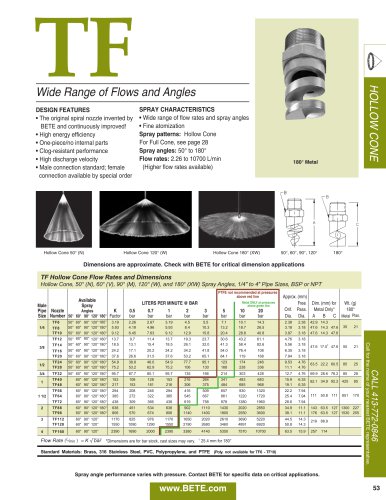

TF

1 Pages

-

TF

1 Pages

-

MaxiPass®

2 Pages

-

HydroClaw®

2 Pages

-

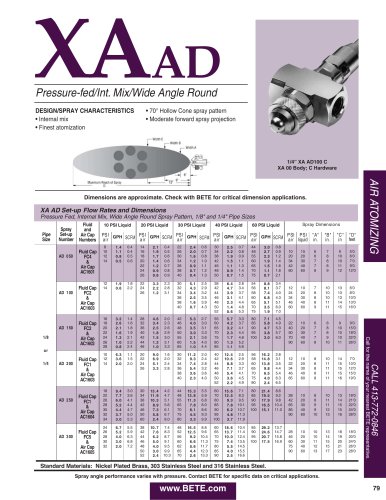

XAAD

1 Pages

-

ST

1 Pages

-

XA Components & Options

1 Pages

-

Engineering Information

9 Pages

-

Custom In-House Fabrications

2 Pages

-

BETE Spray Nozzle Catalog

134 Pages

-

Line Card

2 Pages

-

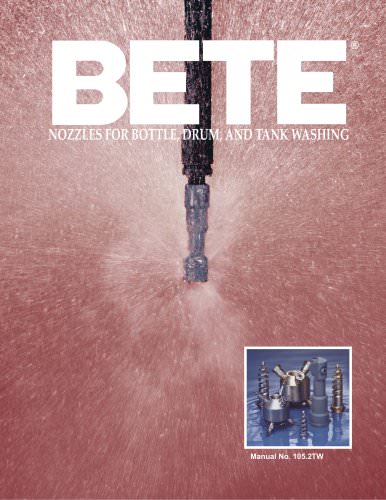

Bottle, Drum & Tank Washing

16 Pages

-

BETE Metric Catalog

132 Pages

-

NFH

1 Pages

-

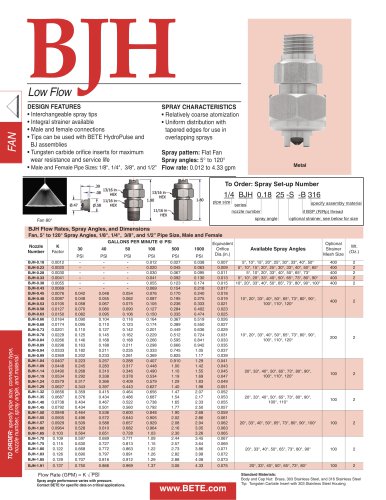

BJH

1 Pages

-

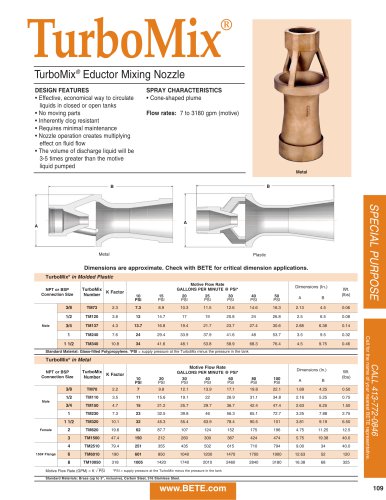

TurboMix

1 Pages

-

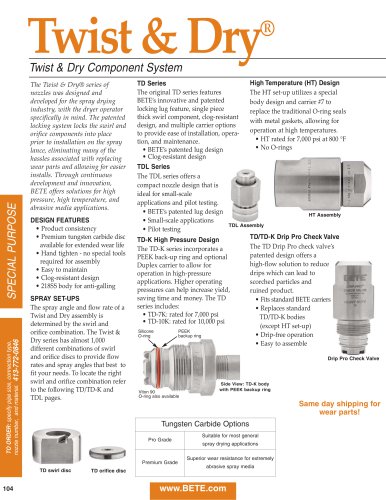

Twist & Dry

5 Pages

-

TF29

1 Pages

-

N fire protection

1 Pages

-

AFF

1 Pages

-

LEM

1 Pages

-

CLUMP

1 Pages

-

HydroWhirl Orbitor

2 Pages

-

HydroWhirl ® Poseidon

1 Pages

-

HydroWhirl S

1 Pages

-

SpiralAir

2 Pages

-

SAM

2 Pages

-

XA Accessories

4 Pages

-

XA

7 Pages

-

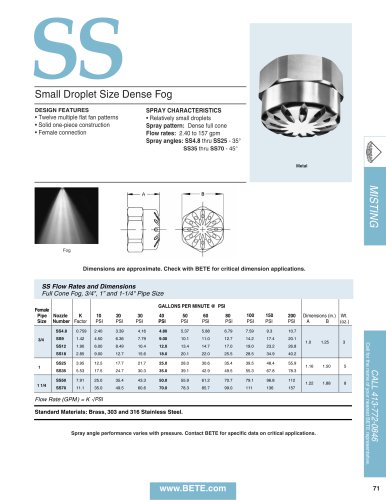

SS

1 Pages

-

UltiMist

1 Pages

-

L

1 Pages

-

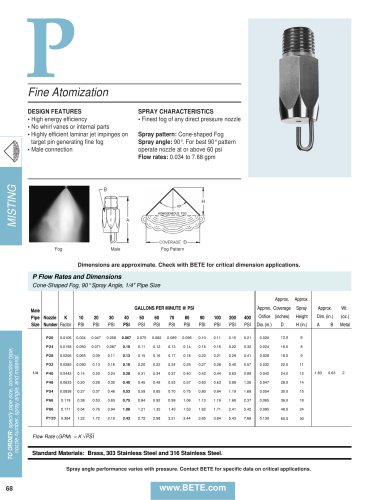

p

1 Pages

-

PJ

1 Pages

-

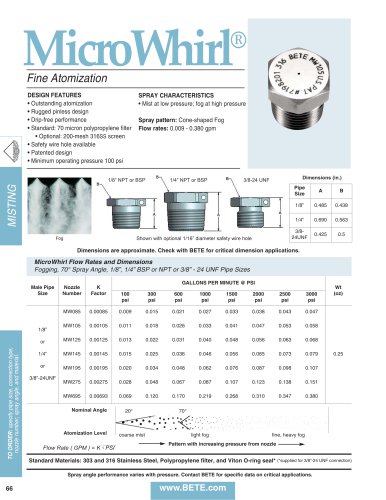

MicroWhirl

1 Pages

-

SPN

1 Pages

-

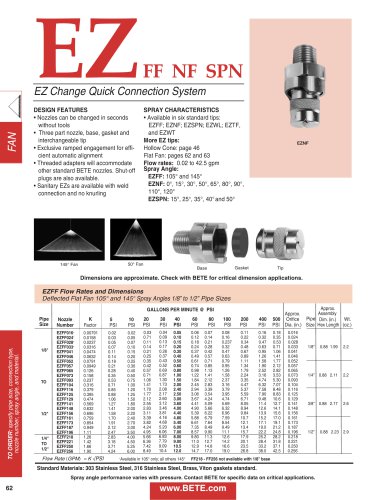

EZ FF NF SPN

2 Pages

-

FF

2 Pages

-

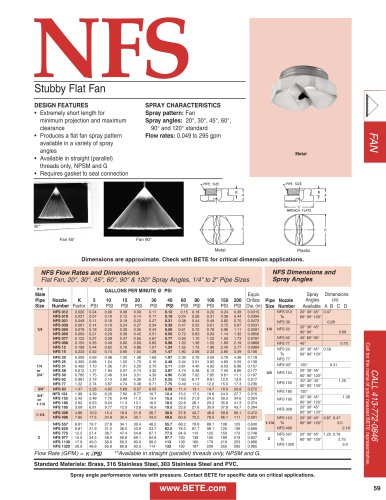

nfs

1 Pages

-

NFD

1 Pages

-

NF

1 Pages

-

NFV

1 Pages

-

HydroPulse

4 Pages

-

BJ

2 Pages

-

Spillback

2 Pages

-

THW

2 Pages

-

NCJ

1 Pages

-

TH

2 Pages

-

WTX

2 Pages

-

WT

2 Pages

-

TC

1 Pages

-

NCFL

1 Pages

-

NCK

1 Pages

-

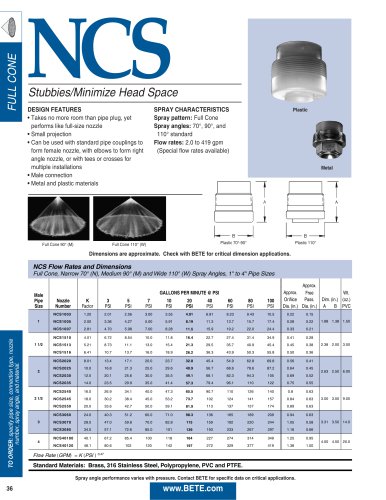

NCS

1 Pages

-

NC

2 Pages

-

SF

3 Pages

-

EZFF

2 Pages

-

WTZ

1 Pages

-

CW

2 Pages

-

WL

1 Pages

-

STXP

1 Pages

-

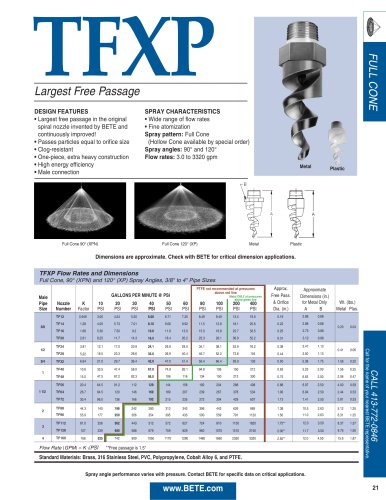

TFXP

1 Pages

-

TF

2 Pages

-

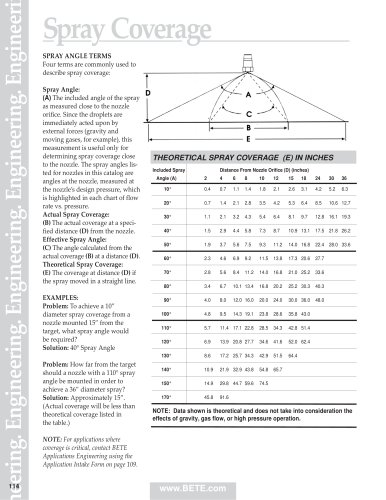

Spray Coverage

1 Pages

-

Bete accessories

1 Pages

-

MATERIALS

1 Pages

-

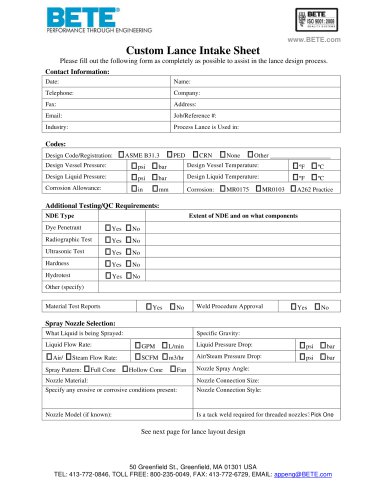

Custom Lance Intake Sheet

2 Pages

-

Pollution Control

8 Pages

-

Food Industry

8 Pages

-

Fire Protection

8 Pages

-

DUR O LOK®

6 Pages

-

Chemical Processing

8 Pages

-

Spray Nozzle Catalogs

127 Pages

-

MaxiPass ® L

1 Pages

-

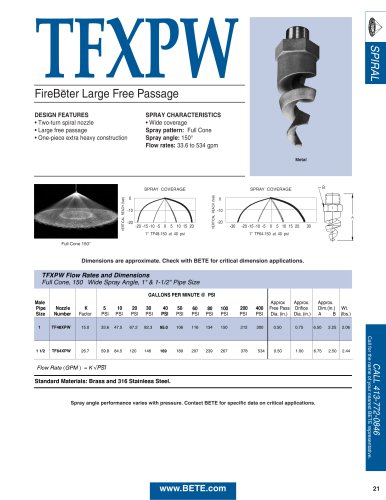

TFXPW

1 Pages

-

N

2 Pages

-

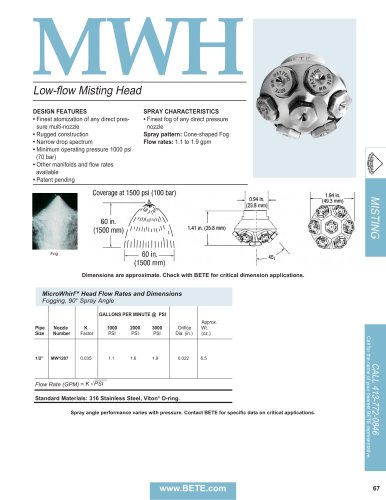

MicroWhirlTM Head (MWH)

1 Pages

-

MaxiPassTM Low Flow (MPL)

1 Pages

-

MaxiPassTM (MP)

2 Pages

-

LP

1 Pages

-

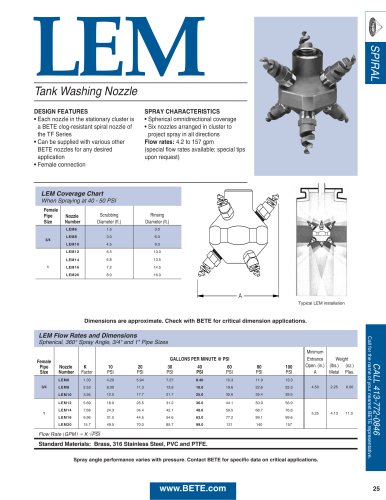

LEM

1 Pages

-

IS

1 Pages

-

FluidBed

1 Pages

-

Spray Drying

11 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

TD/TD-K

4 Pages

-

FINZTM

1 Pages

-

SpiralAirTM

2 Pages

-

SC

2 Pages

Archived catalogs

-

N Fire Protection

2 Pages

-

TW

1 Pages