Website:

BETE

Website:

BETE

Catalog excerpts

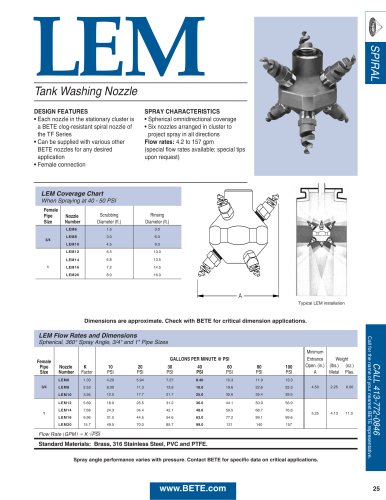

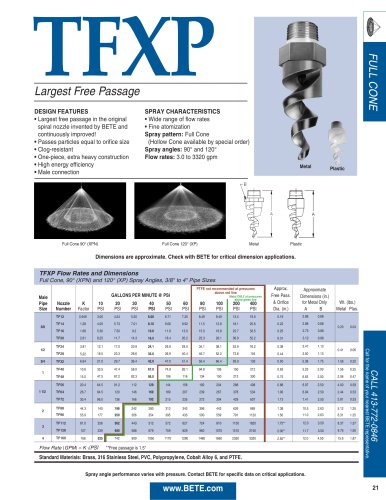

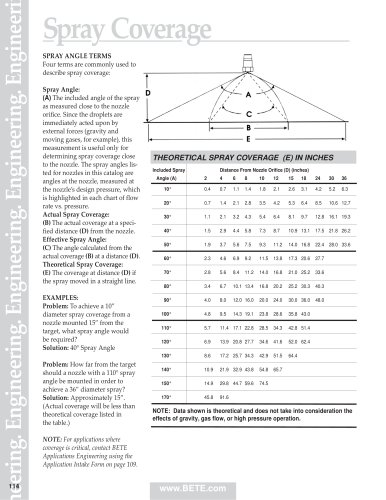

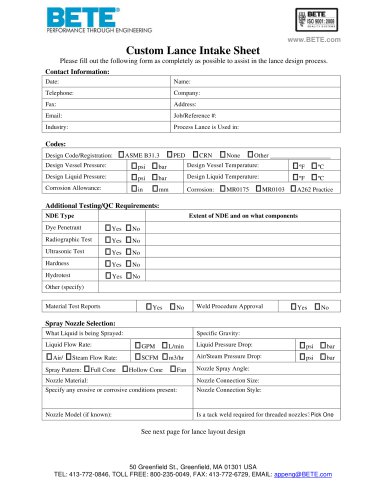

SPIRAL LEM Tank Washing Nozzle DESIGN FEATURES • Each nozzle in the stationary cluster is a BETE clog-resistant spiral nozzle of the TF Series • Can be supplied with various other BETE nozzles for any desired application • Female connection SPRAY CHARACTERISTICS • Spherical omnidirectional coverage • Six nozzles arranged in cluster to project spray in all directions Flow rates: 4.2 to 157 gpm (special flow rates available; special tips upon request) LEM Coverage Chart When Spraying at 40 - 50 PSI Female Pipe Size 1.5 3.0 LEM8 3.0 6.0 LEM10 4.5 9.0 LEM12 6.5 13.0 LEM14 6.8 13.5 LEM16 7.2 14.5 LEM20 1 Rinsing Diameter (ft.) LEM6 3/4 Scrubbing Diameter (ft.) 8.0 16.0 Nozzle Number Typical LEM installation Dimensions are approximate. Check with BETE for critical dimension applications. Spherical, 360° Spray Angle, 3/4" and 1" Pipe Sizes GALLONS PER MINUTE @ PSI Nozzle Number K Factor 10 PSI 20 PSI 30 PSI 40 PSI 60 PSI 80 PSI 100 PSI LEM6 1.33 4.20 5.94 7.27 8.40 10.3 11.9 13.3 LEM8 2.53 8.00 11.3 13.9 16.0 19.6 22.6 25.3 LEM10 3/4 3.95 12.5 17.7 21.7 25.0 30.6 35.4 39.5 LEM12 5.69 18.0 25.5 31.2 36.0 44.1 50.9 7.68 24.3 34.4 42.1 48.6 59.5 68.7 76.8 9.96 31.5 44.5 54.6 63.0 77.2 89.1 15.7 49.5 70.0 85.7 99.0 121 140 2.25 6.00 5.25 4.13 11.0 99.6 LEM20 4.50 56.9 LEM14 LEM16 1 Minimum Entrance Weight Open. (in.) (lbs.) (oz.) A Metal Plas. 157 Flow Rate (GPM ) = K √PSI Standard Materials: Brass, 316 Stainless Steel, PVC and PTFE. Spray angle performance varies with pressure. Contact BETE for specific data on critical applications. www.BETE.com CALL 413-772-0846 Female Pipe Size Call for the name of your nearest BETE representative. LEM Flow Rates and Dimensions 25

Open the catalog to page 1All BETE catalogs and technical brochures

-

WL metric

1 Pages

-

PJ metric

1 Pages

-

NF

1 Pages

-

SpiralAir

2 Pages

-

TW metric

1 Pages

-

TW

1 Pages

-

AFF metric

1 Pages

-

TF10-170

1 Pages

-

TF24

1 Pages

-

TF FM Approved

1 Pages

-

TF metric

1 Pages

-

TF

1 Pages

-

TF

1 Pages

-

MaxiPass®

2 Pages

-

HydroClaw®

2 Pages

-

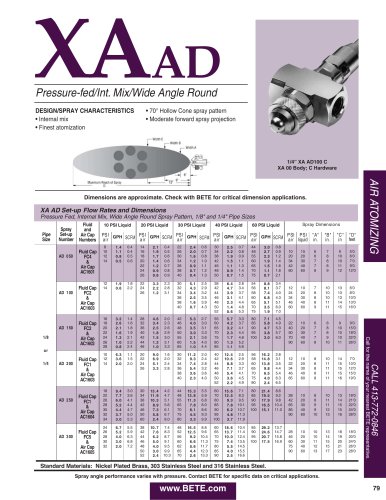

XAAD

1 Pages

-

ST

1 Pages

-

XA Components & Options

1 Pages

-

Engineering Information

9 Pages

-

Custom In-House Fabrications

2 Pages

-

BETE Spray Nozzle Catalog

134 Pages

-

Line Card

2 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

BETE Metric Catalog

132 Pages

-

NFH

1 Pages

-

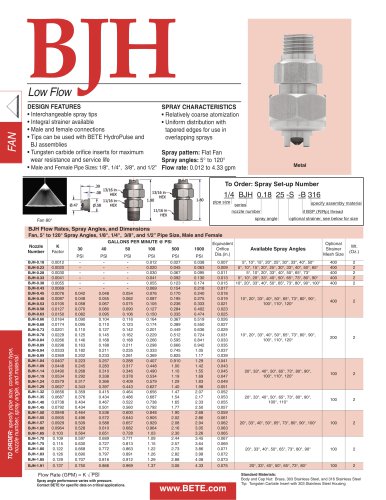

BJH

1 Pages

-

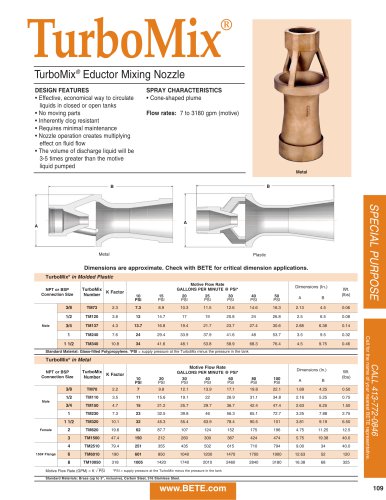

TurboMix

1 Pages

-

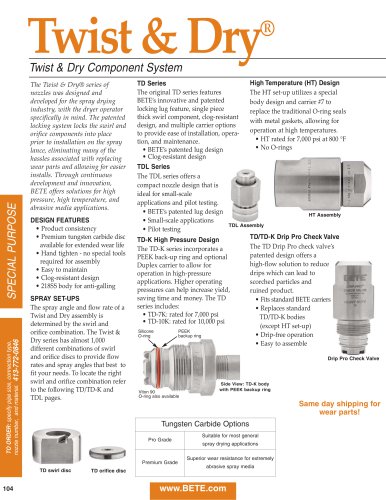

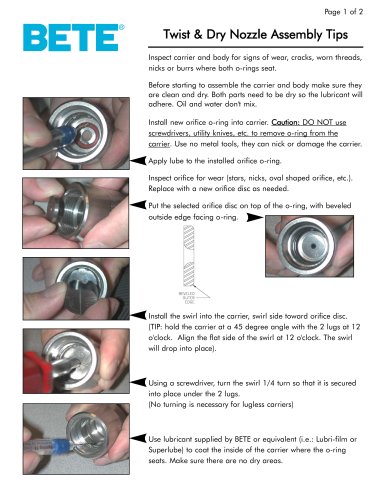

Twist & Dry

5 Pages

-

TF29

1 Pages

-

N fire protection

1 Pages

-

AFF

1 Pages

-

LEM

1 Pages

-

CLUMP

1 Pages

-

HydroWhirl Orbitor

2 Pages

-

HydroWhirl ® Poseidon

1 Pages

-

HydroWhirl S

1 Pages

-

SpiralAir

2 Pages

-

SAM

2 Pages

-

XA Accessories

4 Pages

-

XA

7 Pages

-

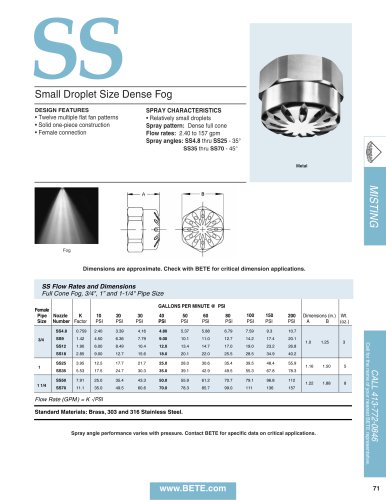

SS

1 Pages

-

UltiMist

1 Pages

-

L

1 Pages

-

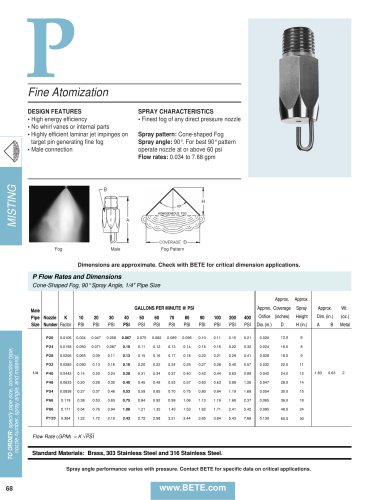

p

1 Pages

-

PJ

1 Pages

-

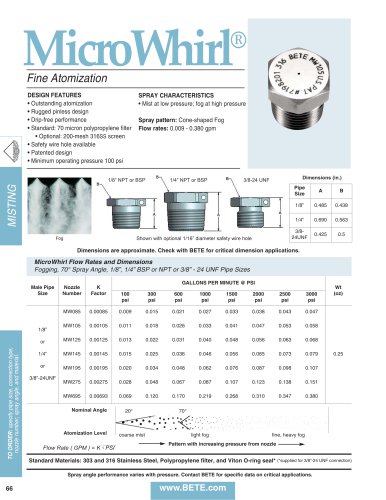

MicroWhirl

1 Pages

-

SPN

1 Pages

-

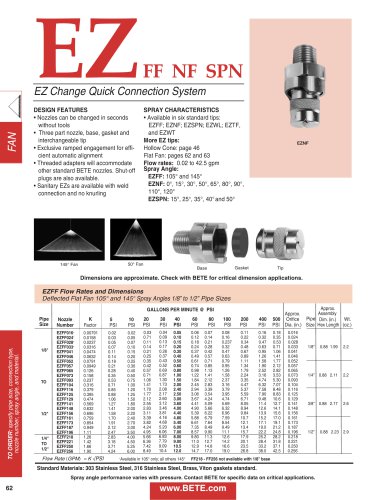

EZ FF NF SPN

2 Pages

-

FF

2 Pages

-

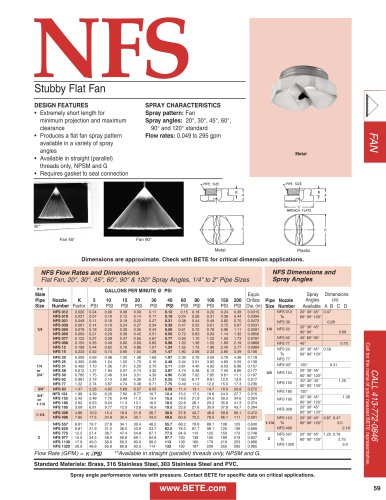

nfs

1 Pages

-

NFD

1 Pages

-

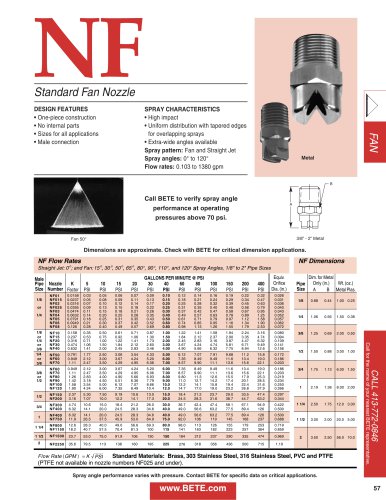

NF

1 Pages

-

NFV

1 Pages

-

HydroPulse

4 Pages

-

BJ

2 Pages

-

Spillback

2 Pages

-

THW

2 Pages

-

NCJ

1 Pages

-

TH

2 Pages

-

WTX

2 Pages

-

WT

2 Pages

-

TC

1 Pages

-

NCFL

1 Pages

-

NCK

1 Pages

-

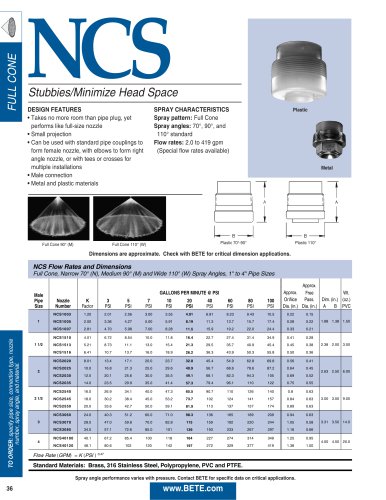

NCS

1 Pages

-

NC

2 Pages

-

SF

3 Pages

-

EZFF

2 Pages

-

WTZ

1 Pages

-

CW

2 Pages

-

WL

1 Pages

-

STXP

1 Pages

-

TFXP

1 Pages

-

TF

2 Pages

-

Spray Coverage

1 Pages

-

Bete accessories

1 Pages

-

MATERIALS

1 Pages

-

Custom Lance Intake Sheet

2 Pages

-

Pollution Control

8 Pages

-

Food Industry

8 Pages

-

Fire Protection

8 Pages

-

DUR O LOK®

6 Pages

-

Chemical Processing

8 Pages

-

Spray Nozzle Catalogs

127 Pages

-

MaxiPass ® L

1 Pages

-

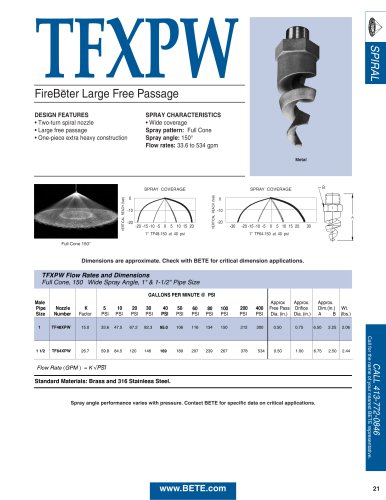

TFXPW

1 Pages

-

N

2 Pages

-

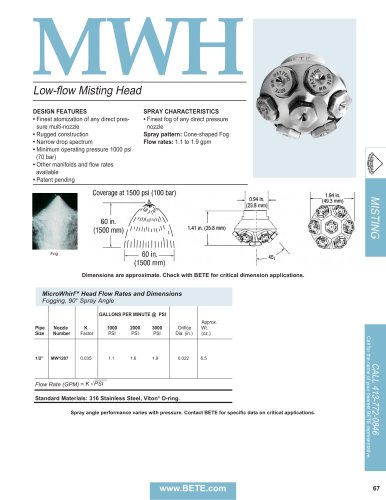

MicroWhirlTM Head (MWH)

1 Pages

-

MaxiPassTM Low Flow (MPL)

1 Pages

-

MaxiPassTM (MP)

2 Pages

-

LP

1 Pages

-

IS

1 Pages

-

FluidBed

1 Pages

-

Spray Drying

11 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

TD/TD-K

4 Pages

-

FINZTM

1 Pages

-

SpiralAirTM

2 Pages

-

SC

2 Pages

Archived catalogs

-

N Fire Protection

2 Pages

-

TW

1 Pages

-

Spray dry manual

25 Pages