Website:

BETE

Website:

BETE

Catalog excerpts

HydroWhirl Orbitor 100 tank cleaning machine is ideal for high impact cleaning The HydroWhirl® Orbitor 100 is a versatile tank cleaning machine designed to meet the high standards required in the food, brewing, beverage, dairy, and chemical industries combining high performance cleaning efficiency with extended operating life and reduced life cycle costs. Advantages of the HydroWhirl Orbitor 100 tank cleaning machine. • The HydroWhirl Orbitor 100 can be stripped, maintained, and rebuilt in less than 15 minutes. • The HydroWhirl Orbitor 100 is self cleaning and self lubricating. • Enhanced external cleaning with dedicated nozzles that clean the external surfaces of the machine and its mounting pipe. • The HydroWhirl Orbitor 100 is ideal for use in small to medium tanks where the product is difficult to clean and where high impact cleaning is required. • Designed with minimum moving parts to ensure extended operating life and reduced down time. • Easily fits through Ø4” (100 mm) openings; or Ø3.35” (85 mm) when nozzle head vertically aligned Key Features and Benefits: • Designed to meet hygienic standards; external surface finish: 0.5 microns Ra or better • Self cleaning; self lubricating = no process contamination • Optimum consumption of water, chemicals, and time = reduced operating costs • Minimum moving parts = reduced lifecycle costs • High impact jets; orbital wash pattern = high efficiency cleaning process • Compact design = will fit through small access flanges and vessel openings • 4 nozzle configurations Available Versions: • 4 nozzle machines • Variable cycle times • Female connections HydroWhirl Orbitor 100 Applications: Typically used where high impingement cleaning is required and where the most efficient use of utilities is necessary. BREWING & WINERIES Bright beer tanks, coppers, maltings, brew kettles, fermenters, storage tanks HydroWhirl Orbitor COATINGS AND PAINTS Storage silos, process vessels, mixers FOOD AND DAIRY Raw milk storage, spray driers, process vessels, storage silos CHEMICAL Process vessels, mixers, storage silos BEVERAGE Process vessels, storage silos BETE Fog Nozzle,Inc. 50 Greenfield St. Greenfield, MA 01301 T (413) 772-0846 F (413) 772-6729 www.bete.

Open the catalog to page 1

HydroWhirl Orbitor 100 High Impact Rotary Tank Cleaning Machine DESIGN FEATURES • Easily field-serviced to reduce maintenance costs • Minimum moving parts to extend operating life • Self cleaning; self lubricating • High-impact jets; orbital wash pattern = high efficiency cleaning process • Ideal for small to medium tanks, easily fits through Ø4” (100 mm) openings • 4 nozzle configurations • Female connections SPRAY CHARACTERISTICS • 360° wash pattern • Variable cycle times • High impact cleaning Flow rates: 12 - 52.4 gpm Working Pressure: 45 - 145 psi Materials: Housing and Nozzle Head:...

Open the catalog to page 2All BETE catalogs and technical brochures

-

WL metric

1 Pages

-

PJ metric

1 Pages

-

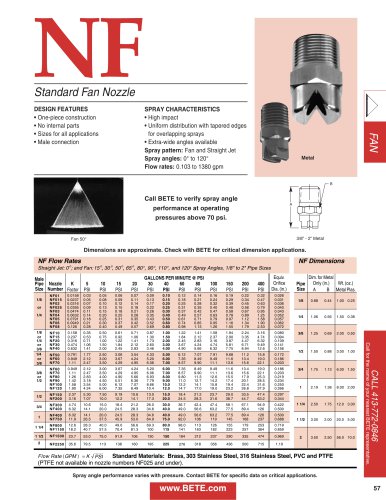

NF

1 Pages

-

SpiralAir

2 Pages

-

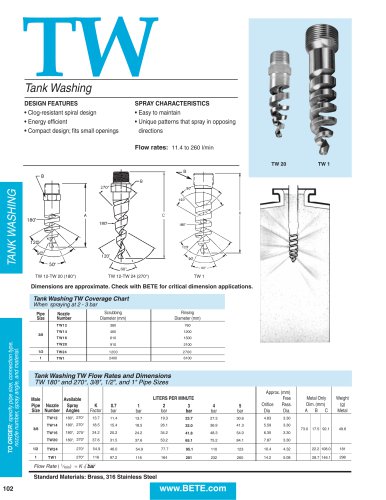

TW metric

1 Pages

-

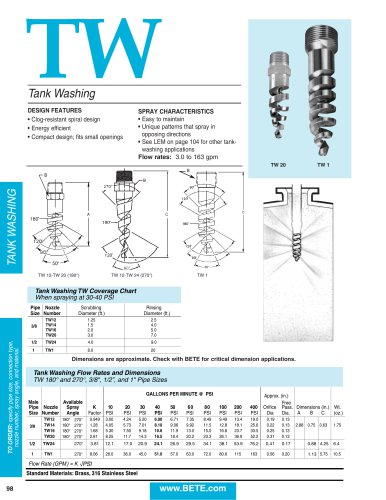

TW

1 Pages

-

AFF metric

1 Pages

-

TF10-170

1 Pages

-

TF24

1 Pages

-

TF FM Approved

1 Pages

-

TF metric

1 Pages

-

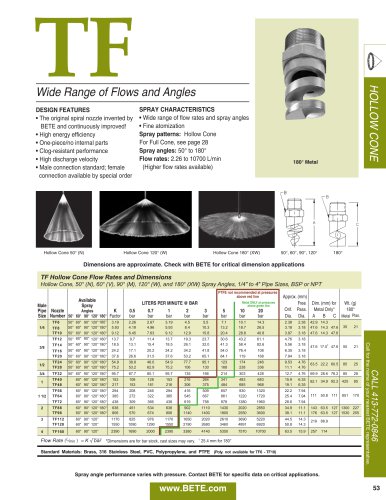

TF

1 Pages

-

TF

1 Pages

-

MaxiPass®

2 Pages

-

HydroClaw®

2 Pages

-

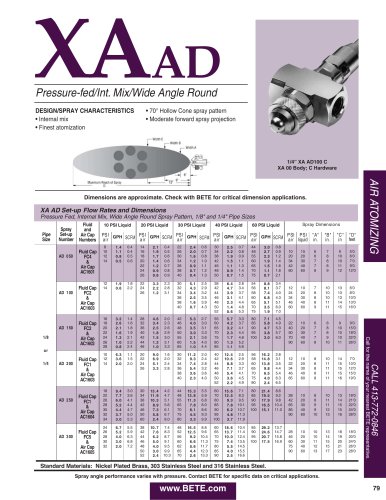

XAAD

1 Pages

-

ST

1 Pages

-

XA Components & Options

1 Pages

-

Engineering Information

9 Pages

-

Custom In-House Fabrications

2 Pages

-

BETE Spray Nozzle Catalog

134 Pages

-

Line Card

2 Pages

-

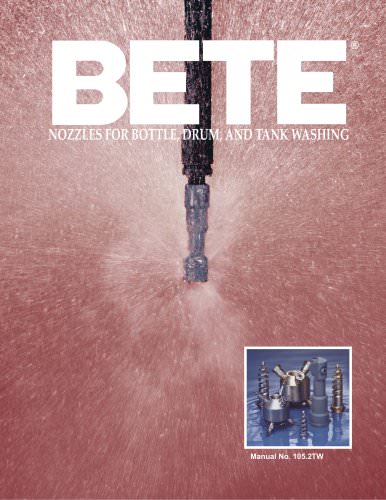

Bottle, Drum & Tank Washing

16 Pages

-

BETE Metric Catalog

132 Pages

-

NFH

1 Pages

-

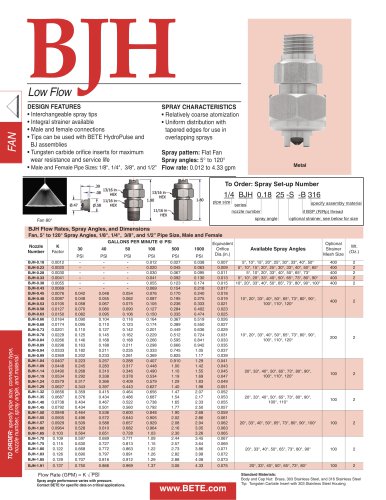

BJH

1 Pages

-

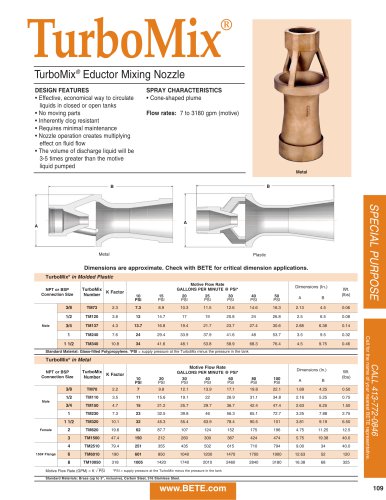

TurboMix

1 Pages

-

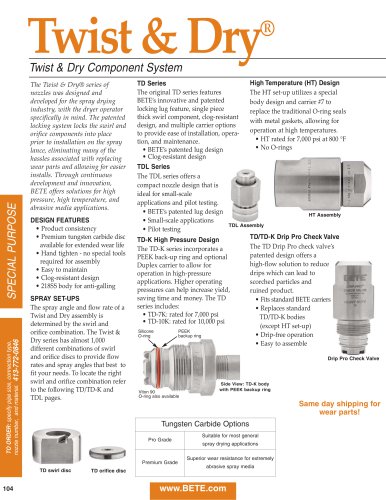

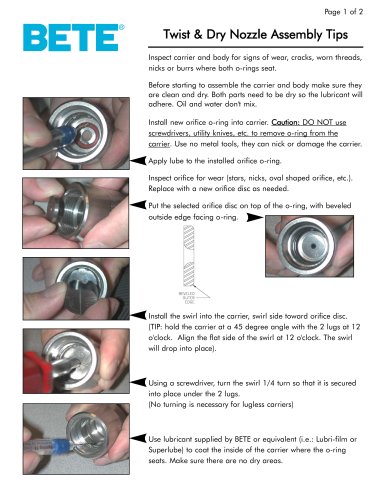

Twist & Dry

5 Pages

-

TF29

1 Pages

-

N fire protection

1 Pages

-

AFF

1 Pages

-

LEM

1 Pages

-

CLUMP

1 Pages

-

HydroWhirl ® Poseidon

1 Pages

-

HydroWhirl S

1 Pages

-

SpiralAir

2 Pages

-

SAM

2 Pages

-

XA Accessories

4 Pages

-

XA

7 Pages

-

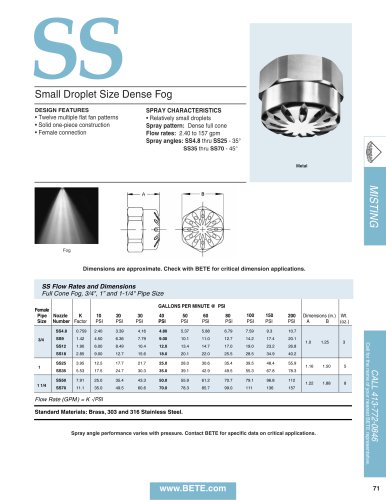

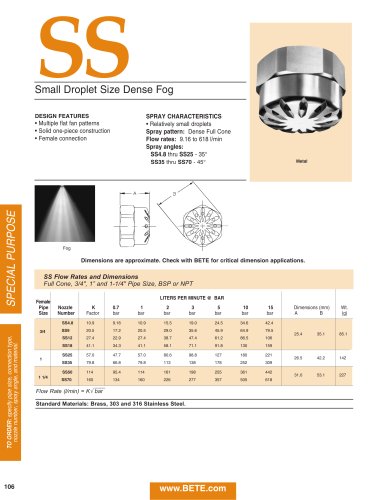

SS

1 Pages

-

UltiMist

1 Pages

-

L

1 Pages

-

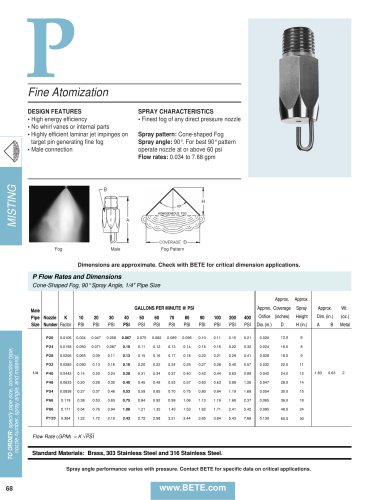

p

1 Pages

-

PJ

1 Pages

-

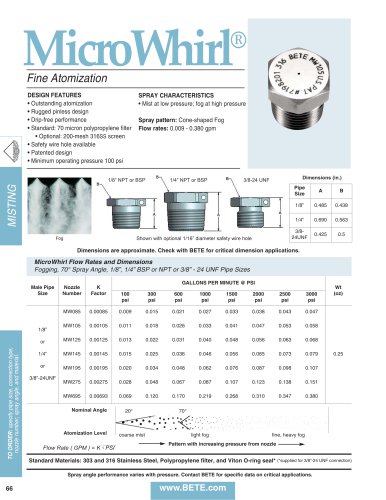

MicroWhirl

1 Pages

-

SPN

1 Pages

-

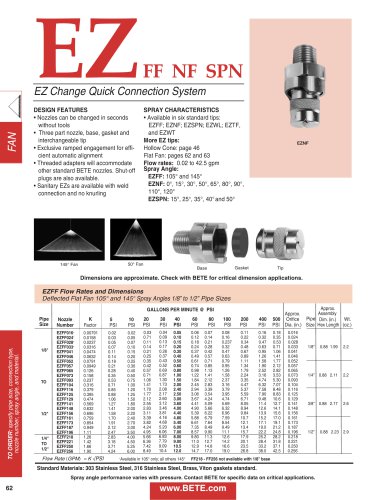

EZ FF NF SPN

2 Pages

-

FF

2 Pages

-

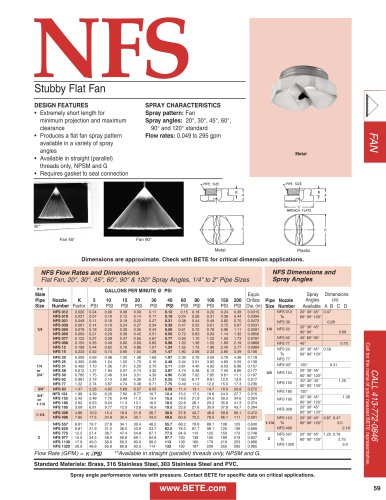

nfs

1 Pages

-

NFD

1 Pages

-

NF

1 Pages

-

NFV

1 Pages

-

HydroPulse

4 Pages

-

BJ

2 Pages

-

Spillback

2 Pages

-

THW

2 Pages

-

NCJ

1 Pages

-

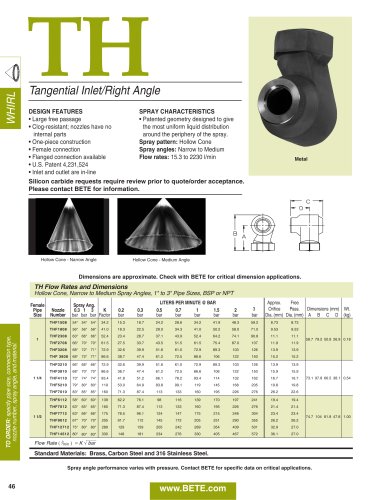

TH

2 Pages

-

WTX

2 Pages

-

WT

2 Pages

-

TC

1 Pages

-

NCFL

1 Pages

-

NCK

1 Pages

-

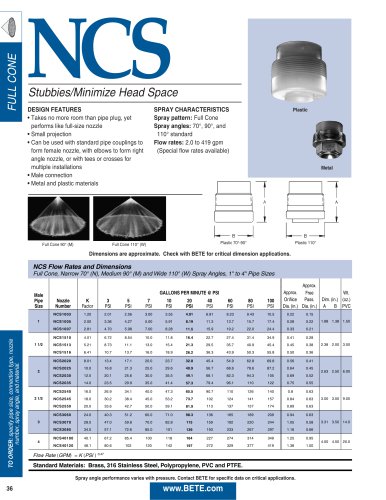

NCS

1 Pages

-

NC

2 Pages

-

SF

3 Pages

-

EZFF

2 Pages

-

WTZ

1 Pages

-

CW

2 Pages

-

WL

1 Pages

-

STXP

1 Pages

-

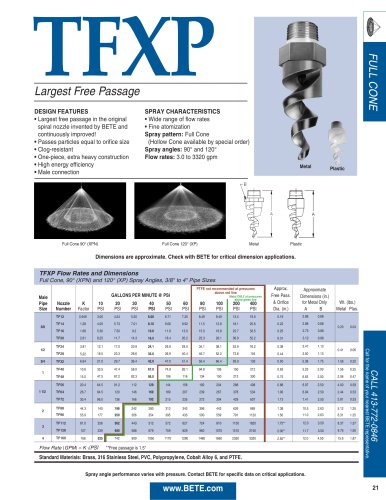

TFXP

1 Pages

-

TF

2 Pages

-

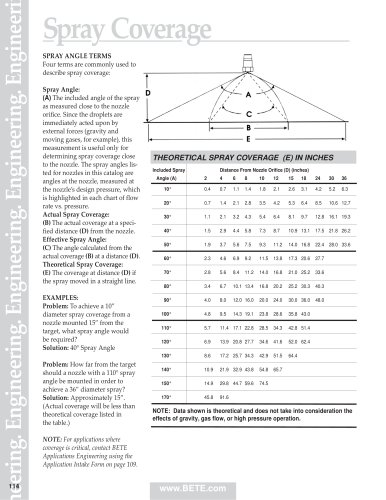

Spray Coverage

1 Pages

-

Bete accessories

1 Pages

-

MATERIALS

1 Pages

-

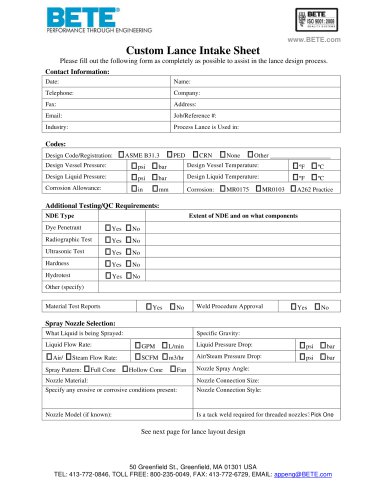

Custom Lance Intake Sheet

2 Pages

-

Pollution Control

8 Pages

-

Food Industry

8 Pages

-

Fire Protection

8 Pages

-

DUR O LOK®

6 Pages

-

Chemical Processing

8 Pages

-

Spray Nozzle Catalogs

127 Pages

-

MaxiPass ® L

1 Pages

-

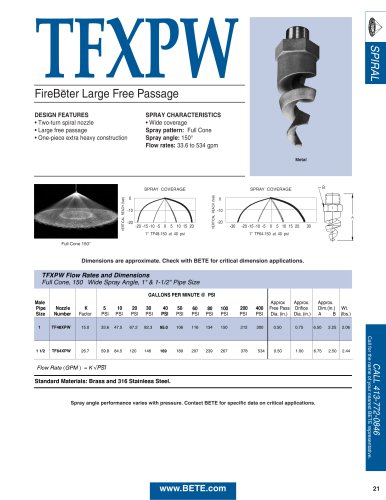

TFXPW

1 Pages

-

N

2 Pages

-

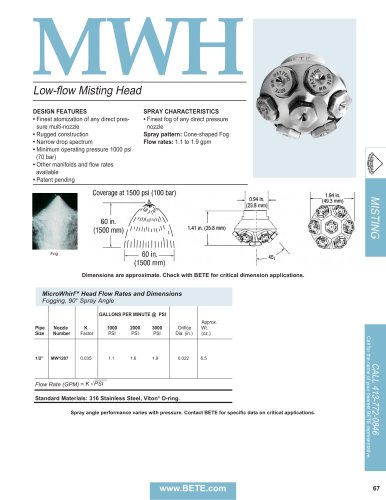

MicroWhirlTM Head (MWH)

1 Pages

-

MaxiPassTM Low Flow (MPL)

1 Pages

-

MaxiPassTM (MP)

2 Pages

-

LP

1 Pages

-

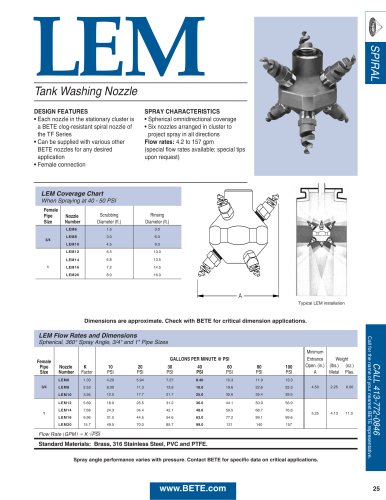

LEM

1 Pages

-

IS

1 Pages

-

FluidBed

1 Pages

-

Spray Drying

11 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

TD/TD-K

4 Pages

-

FINZTM

1 Pages

-

SpiralAirTM

2 Pages

-

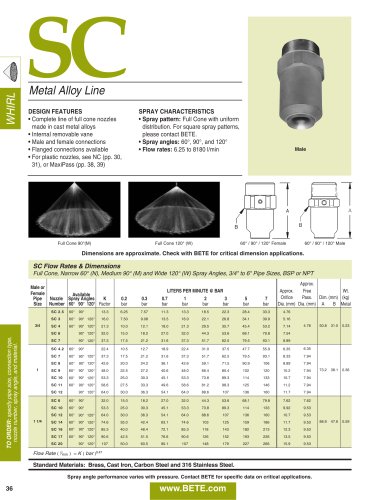

SC

2 Pages

Archived catalogs

-

N Fire Protection

2 Pages

-

TW

1 Pages

-

Spray dry manual

25 Pages