Catalog excerpts

lightweight connec The I coupling meets the requirements of the following codes: ASME Boiler and Pressure Vessel Code, Section VIE IQBETEQ U A L ASME B31.1, Code for Pressure Piping S en onni <>iWi ASME B31.3, Code for Process Piping f m m™m ®2004 BETE Fog Nozzle, Inc., all rights reserved

Open the catalog to page 1

Compact Pipe Coupling DUR O LOK® Materials • Carbon steel • Stainless steel - 304, 316, 321 • Other materials available • Material traceability available DUR O LOK® Quality • Designed to ASME B&PV Code Section VIII, ASME B31.1 and ASME B31.3 • Quality assurance to ISO 9001:2000 DUR O LOK® Pipe Couplings - Dimensions (inches), Ratings (PSI), and Assumed Moments (ft-lb) Data provided below is for the o-ring design. Similar information is available upon request for the high temperature gasket seal design. Pipe Sched. “C” Tapered Ring length *DUR O LOK® Pipe Couplings - Note: Values for...

Open the catalog to page 2

Save Time and Money with Fast, ® Simple, Lightweight DUR O LOK Pipe Couplings Tapered I.D. Hub Split Coupler O-Ring or High Temperature Gasket Wedge Shaped Teeth Split Coupler The DUR O LOK® wedge system The heart of the DUR O LOK® design is the system of wedge-shaped, circumferential teeth located on the outside diameter of the hubs and on the inside diameter of the mating split coupler. The wedging action of the teeth compresses the gasket and brings the hub ends into contact with each other. The outside diameter of the split coupler is tapered. A ring with a tapered inside diameter...

Open the catalog to page 3

The Light Weight, Threadless, Boltless Coupling Alternative The performance superiority, space, and weight provided by DUR O LOK® couplings make them the preferred choice in many pipeconnecting applications. DUR O LOK® couplings are all-purpose, lightweight connectors designed to replace standard ANSI flanges. The design of DUR O LOK® couplings ensures reliable operation over a wide range of temperatures. DUR O LOK® couplings have been used in refinery applications for many years and are specified by UOP for use in CCRTM PlatformingTM, OleflexTM and SorbexTM processing units, as well as in...

Open the catalog to page 4

Heavy Duty Couplings Don DUR O LOK® / Flange - Weight and Dimension Comparison DUR O LOK® Pipe Size 1 1.25 1.5 2 2.5 3 3.5 4 6 8 Weld Neck Flanges Overall Overall Approx Pipe Diameter Length Weight Schedule (in.) (in.) (lb.) 80 80 XXS 80 160 80 80 160 80 80 www.durolok.com ®2004 BETE Fog Nozzle, Inc., all rights reserved

Open the catalog to page 5

Don’t Have to Weigh a Ton www.durolok.com ®2004 BETE Fog Nozzle, Inc., all rights reserved

Open the catalog to page 6All BETE catalogs and technical brochures

-

WL metric

1 Pages

-

PJ metric

1 Pages

-

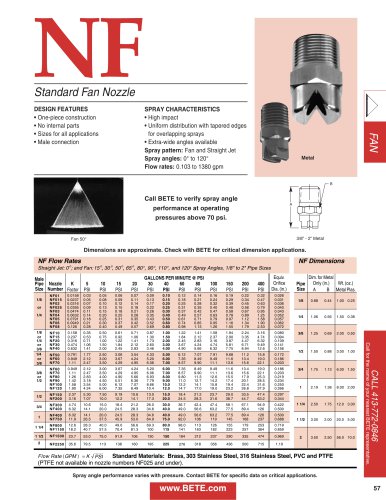

NF

1 Pages

-

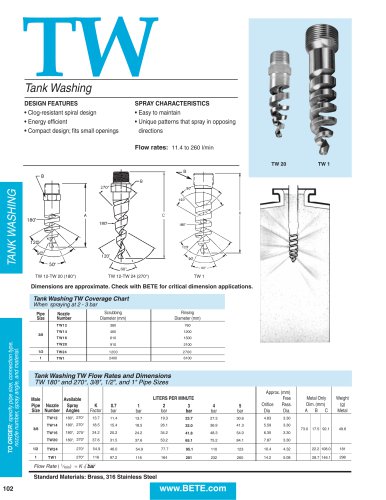

TW metric

1 Pages

-

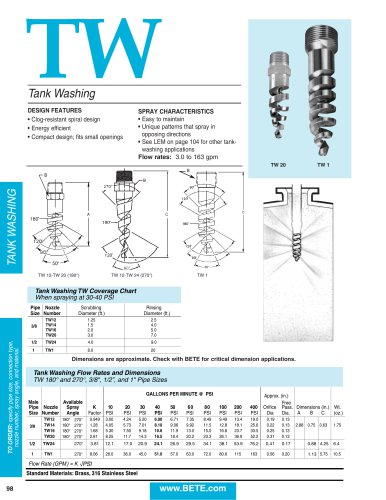

TW

1 Pages

-

AFF metric

1 Pages

-

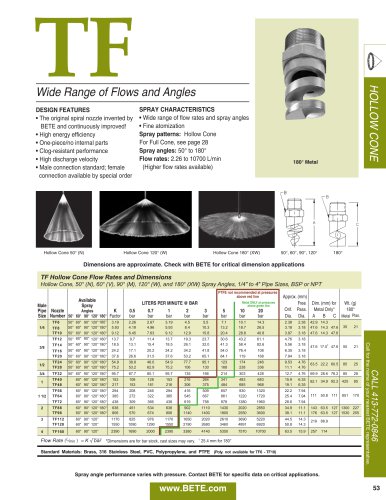

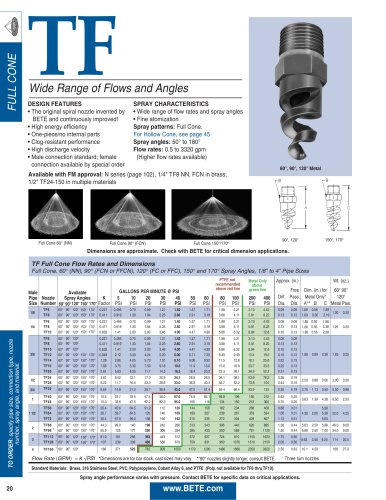

TF10-170

1 Pages

-

TF24

1 Pages

-

TF FM Approved

1 Pages

-

TF metric

1 Pages

-

MaxiPass®

2 Pages

-

HydroClaw®

2 Pages

-

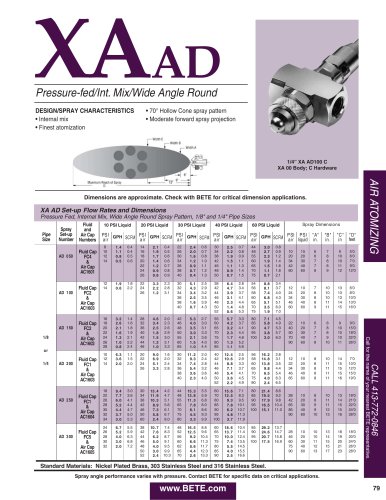

XAAD

1 Pages

-

ST

1 Pages

-

XA Components & Options

1 Pages

-

Engineering Information

9 Pages

-

Custom In-House Fabrications

2 Pages

-

BETE Spray Nozzle Catalog

134 Pages

-

Line Card

2 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

BETE Metric Catalog

132 Pages

-

NFH

1 Pages

-

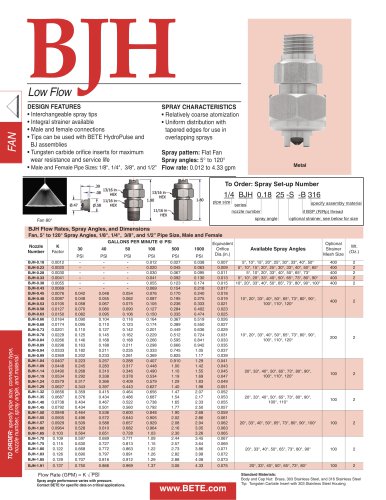

BJH

1 Pages

-

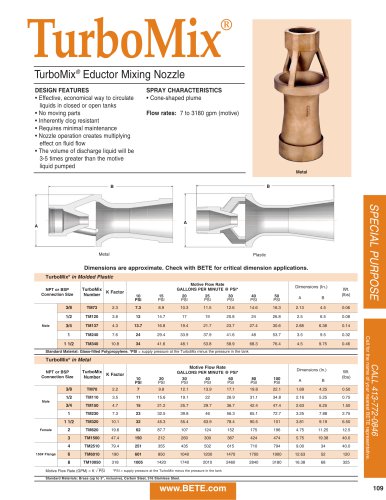

TurboMix

1 Pages

-

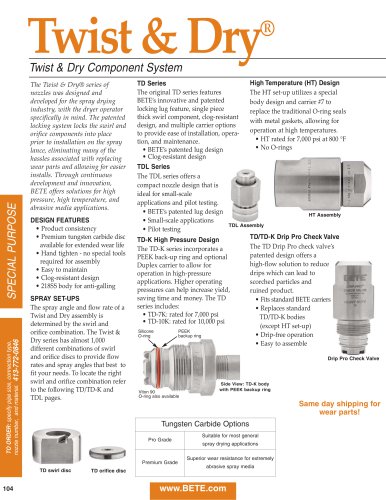

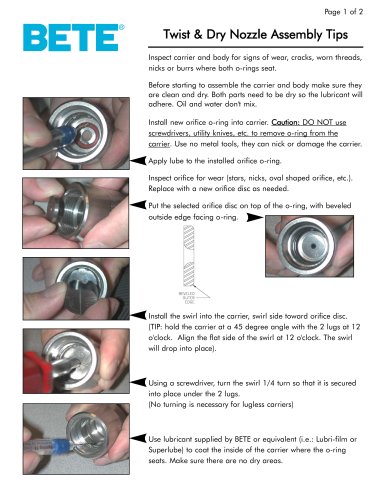

Twist & Dry

5 Pages

-

TF29

1 Pages

-

N fire protection

1 Pages

-

AFF

1 Pages

-

LEM

1 Pages

-

CLUMP

1 Pages

-

HydroWhirl Orbitor

2 Pages

-

HydroWhirl ® Poseidon

1 Pages

-

HydroWhirl S

1 Pages

-

SAM

2 Pages

-

XA Accessories

4 Pages

-

XA

7 Pages

-

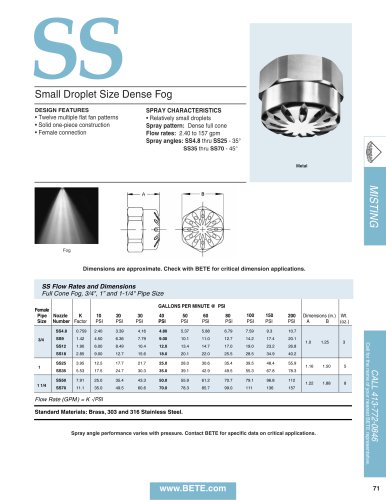

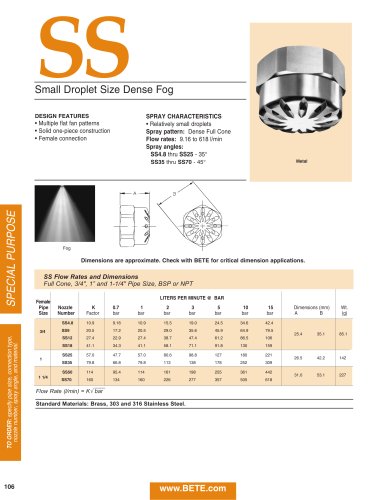

SS

1 Pages

-

UltiMist

1 Pages

-

L

1 Pages

-

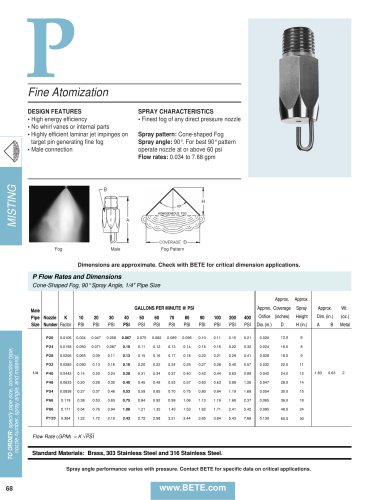

p

1 Pages

-

PJ

1 Pages

-

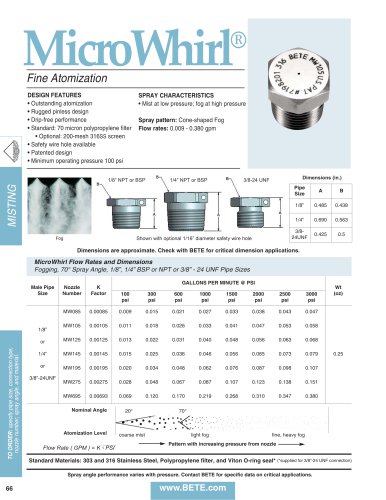

MicroWhirl

1 Pages

-

SPN

1 Pages

-

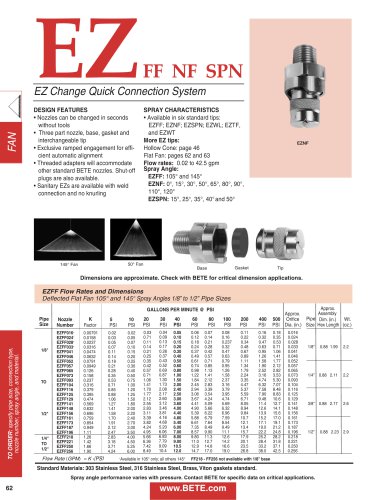

EZ FF NF SPN

2 Pages

-

FF

2 Pages

-

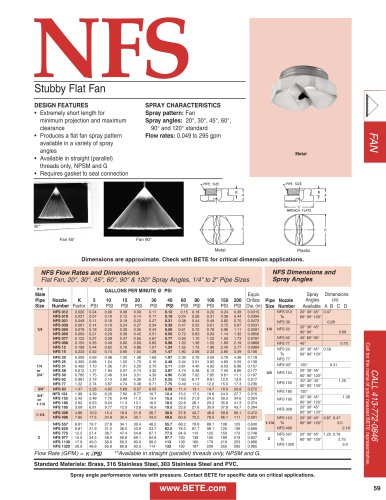

nfs

1 Pages

-

NFD

1 Pages

-

NF

1 Pages

-

NFV

1 Pages

-

HydroPulse

4 Pages

-

BJ

2 Pages

-

Spillback

2 Pages

-

THW

2 Pages

-

NCJ

1 Pages

-

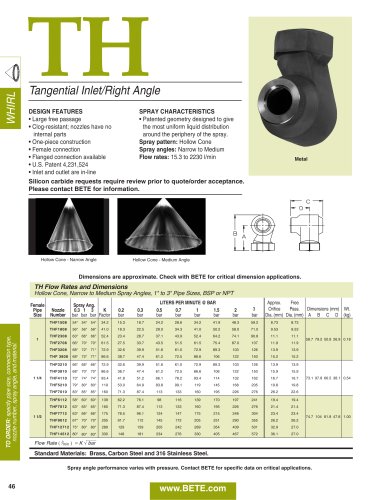

TH

2 Pages

-

WTX

2 Pages

-

WT

2 Pages

-

TC

1 Pages

-

NCFL

1 Pages

-

NCK

1 Pages

-

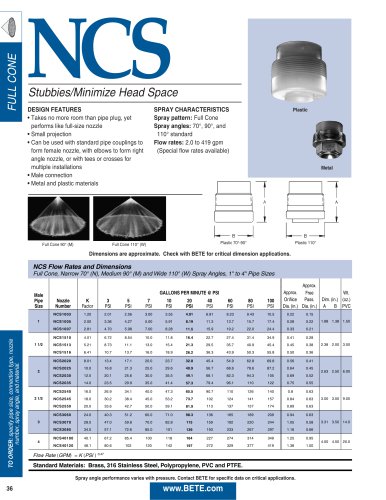

NCS

1 Pages

-

NC

2 Pages

-

SF

3 Pages

-

EZFF

2 Pages

-

WTZ

1 Pages

-

CW

2 Pages

-

WL

1 Pages

-

STXP

1 Pages

-

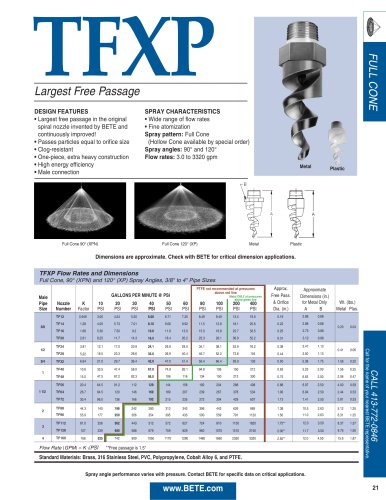

TFXP

1 Pages

-

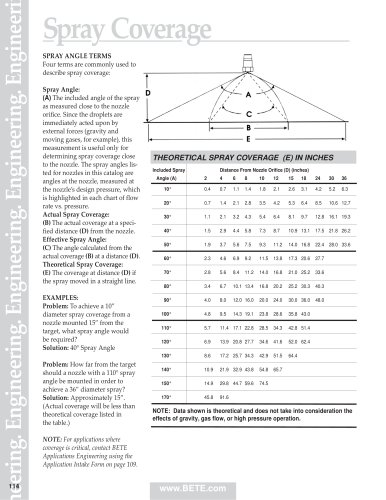

Spray Coverage

1 Pages

-

Bete accessories

1 Pages

-

MATERIALS

1 Pages

-

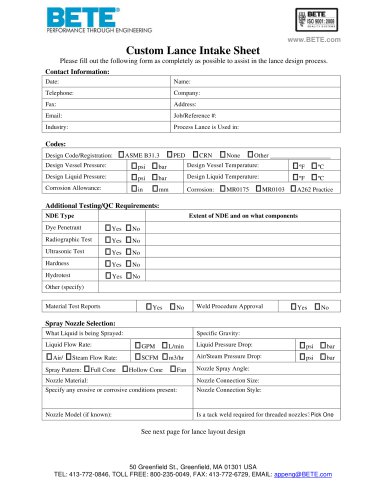

Custom Lance Intake Sheet

2 Pages

-

Pollution Control

8 Pages

-

Food Industry

8 Pages

-

Fire Protection

8 Pages

-

Chemical Processing

8 Pages

-

Spray Nozzle Catalogs

127 Pages

-

MaxiPass ® L

1 Pages

-

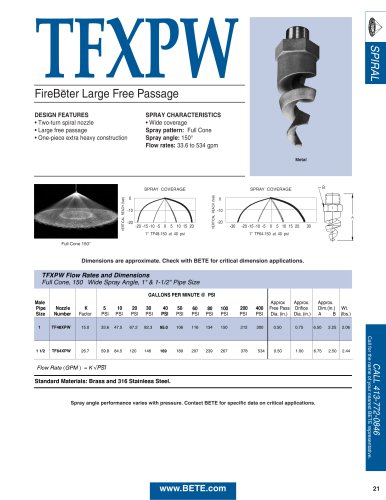

TFXPW

1 Pages

-

N

2 Pages

-

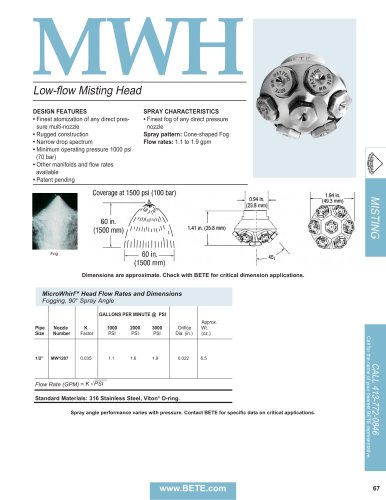

MicroWhirlTM Head (MWH)

1 Pages

-

MaxiPassTM Low Flow (MPL)

1 Pages

-

MaxiPassTM (MP)

2 Pages

-

LP

1 Pages

-

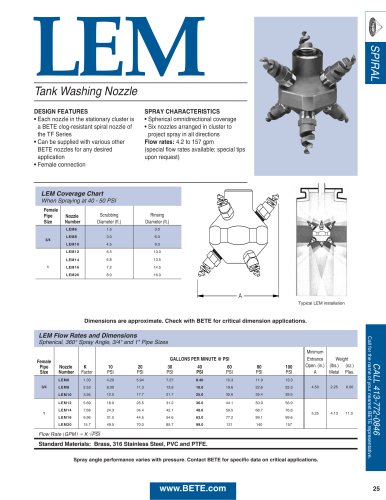

LEM

1 Pages

-

IS

1 Pages

-

FluidBed

1 Pages

-

Spray Drying

11 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

TD/TD-K

4 Pages

-

FINZTM

1 Pages

-

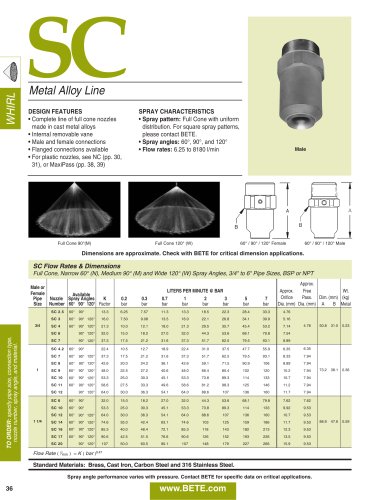

SC

2 Pages

Archived catalogs

-

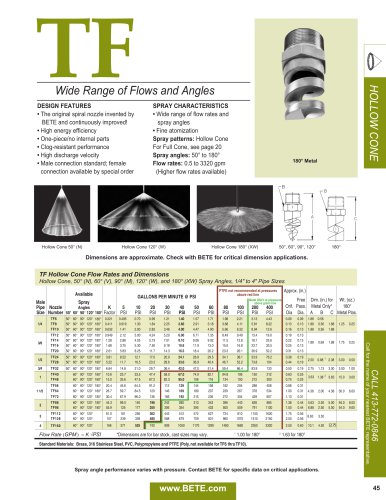

TF_2021

1 Pages

-

TF

1 Pages

-

SpiralAir

2 Pages

-

N Fire Protection

2 Pages

-

TW

1 Pages

-

SpiralAirTM

2 Pages

-

Spray dry manual

25 Pages