Website:

BETE

Website:

BETE

Catalog excerpts

NOZZLES FOR CHEMICAL PROCESSING

Open the catalog to page 1

Choosing the Best Nozzles BETE innovations provide solutions to problems encountered with traditional nozzle designs. Choosing the correct nozzle for your chemical processing application is critical. BETE’s experience as the creator of the original spiral nozzle has put us in the unique position of understanding the best methods of producing very finely atomized spray. When we design a nozzle, we begin by understanding what specific spray atomization characteristics are necessary for a particular chemical process to succeed. We then engineer a nozzle that performs to those characteristics....

Open the catalog to page 2

For Your Chemical Process Gas Conditioning/Humidification: Maximizing gasliquid contact is the primary concern, nozzle selection focuses on the atomization and drop size characteristics of the spray nozzle design. Air Atomizing, Spiral, and Impingement nozzle designs are usually recommended. See page 4. Distribution/ Mixing: The nozzle characteristics of greatest interest for distributing and mixing should be flow rate and a non-clogging design. Whirl nozzles are most commonly used. See page 5. Pollution Control: There are many areas of pollution control. A brief summary is given here; for...

Open the catalog to page 3

Gas Conditioning, Humidification Drying Kilns, Curing Rooms, Electro-static Precipitators BETE nozzles are frequently used to control static electricity in processing lines. BETE’s superior drip-resistant air atomizing nozzles easily humidify ducts, kilns, and curing rooms. When air lines are not available, use BETE directpressure impingement nozzles. At higher flow rates, when clogging is a problem, or when greater coverage is needed, spiral nozzles may be used. IS Specialty • Specialty fan design produces a rectangular pattern when mounted in pairs. • Lower-to-moderate flow rates 0.5 to...

Open the catalog to page 4

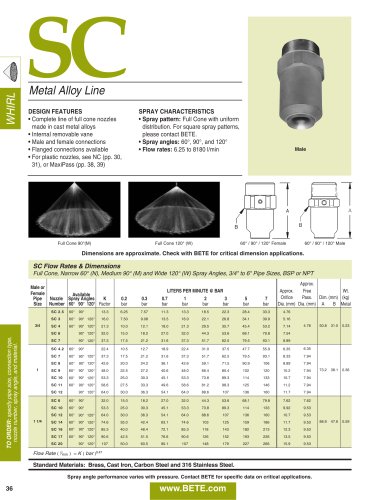

Distribution, Mixing Distribute Liquids on Packing, Horticultural Beds, Mixing BETE’s nozzles are designed to handle many types of mixing and distribution, including FCCU feed distribution nozzles, distributing liquids onto packed beds or mixing chemical compounds. Distribution nozzles usually feature wide spray angles, high through-put, medium-to-coarse atomization, and moderate operating pressures. BETE has many unique designs specially developed for these applications. NC and SC Whirl • Full cone nozzles available in a variety of plastic (NC), or metals (SC) • Large range of flow rates...

Open the catalog to page 5

Pollution Control Scrub Gases, Evaporate Ponds, and Suppress Dust BETE is a world leader in nozzle design for pollution control and denoxification. BETE nozzles are used for quencher, pre-scrubber, absorber, direct contact, open tower, and mist eliminator washing applications. Water Pollution TF, TFXP, and MaxiPass nozzles give optimum performance in wastewater aeration in meeting EPA oxygen content requirements. ST, STXP Spiral • Full cone spiral nozzles produce the best atomization and clog resistance of any direct pressure nozzle. • Standard two- or three-piece construction with no...

Open the catalog to page 6

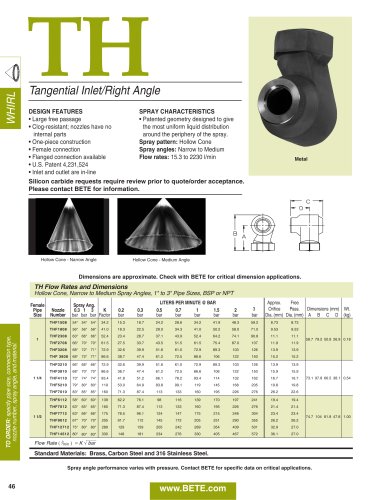

Evaporative Cooling Cooling Flue Gases, Temperature Sensitive Equipment TF and TFXP Spiral • One-piece spiral construction • Very large free passage for greater clog resistance • Spray angles available from 50° to 180° • Produces high percentage of droplets in the 100 1,000 micron range • Direct pressure nozzle • Excellent when used for evaporative disposal with dirty, stringy liquids • Fine atomization TH Tangential Whirl • Right-angle mounting • No internal parts • Most even distribution of any hollow cone whirl in the industry • Large range of flow rates: 5 to 1500 gpm (19 to 5677 L/min)...

Open the catalog to page 7

BETE FOG NOZZLE, INC. 50 GREENFIELD STREET GREENFIELD, MA 01301 TEL: 413- 772-0846, FAX: 413-772-6729 www.bete.com, email: sales@bete.com ©2011 BETE Fog Nozzle, Inc. All rights reserved. BETE is a registered trademark of BETE Fog Nozzle, Inc. MaxiPass and SpiralAir are trademarks of BETE Fog Nozzle, Inc.

Open the catalog to page 8All BETE catalogs and technical brochures

-

WL metric

1 Pages

-

PJ metric

1 Pages

-

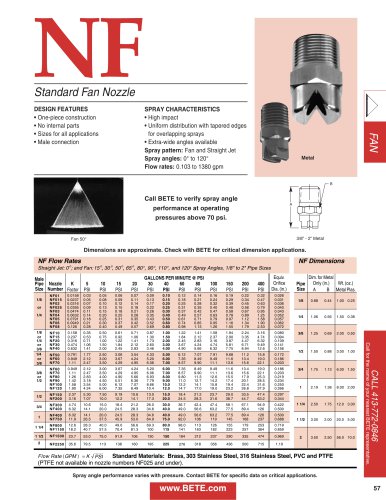

NF

1 Pages

-

SpiralAir

2 Pages

-

TW metric

1 Pages

-

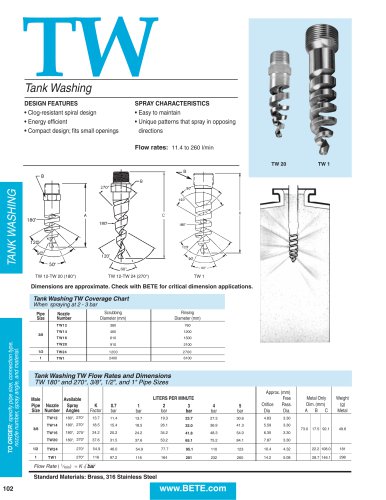

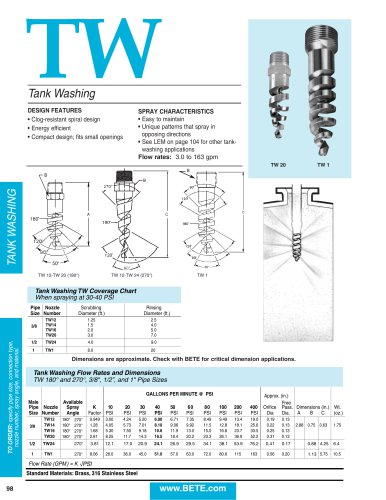

TW

1 Pages

-

AFF metric

1 Pages

-

TF10-170

1 Pages

-

TF24

1 Pages

-

TF FM Approved

1 Pages

-

TF metric

1 Pages

-

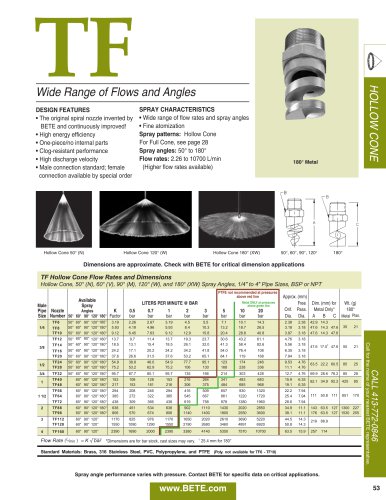

TF

1 Pages

-

TF

1 Pages

-

MaxiPass®

2 Pages

-

HydroClaw®

2 Pages

-

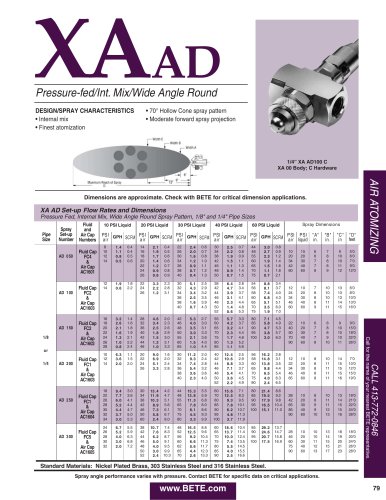

XAAD

1 Pages

-

ST

1 Pages

-

XA Components & Options

1 Pages

-

Engineering Information

9 Pages

-

Custom In-House Fabrications

2 Pages

-

BETE Spray Nozzle Catalog

134 Pages

-

Line Card

2 Pages

-

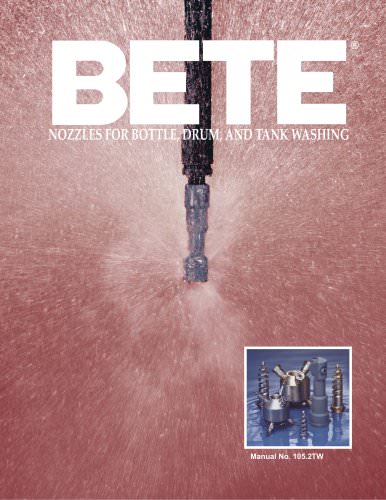

Bottle, Drum & Tank Washing

16 Pages

-

BETE Metric Catalog

132 Pages

-

NFH

1 Pages

-

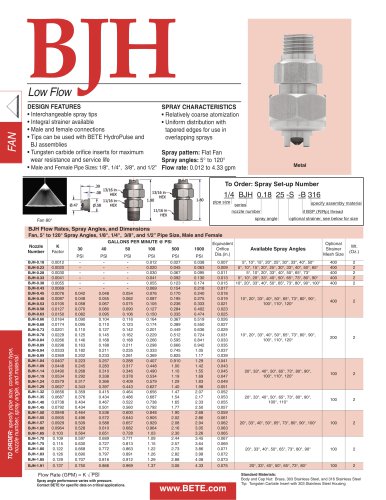

BJH

1 Pages

-

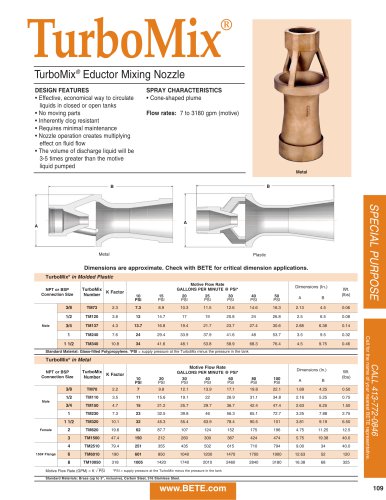

TurboMix

1 Pages

-

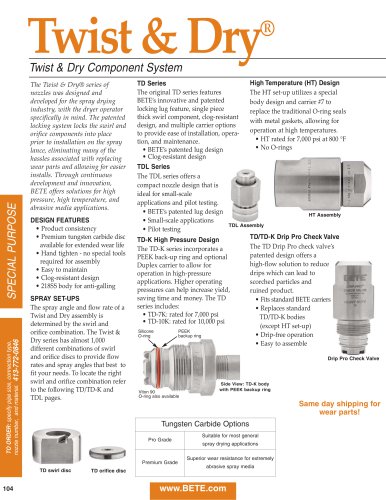

Twist & Dry

5 Pages

-

TF29

1 Pages

-

N fire protection

1 Pages

-

AFF

1 Pages

-

LEM

1 Pages

-

CLUMP

1 Pages

-

HydroWhirl Orbitor

2 Pages

-

HydroWhirl ® Poseidon

1 Pages

-

HydroWhirl S

1 Pages

-

SpiralAir

2 Pages

-

SAM

2 Pages

-

XA Accessories

4 Pages

-

XA

7 Pages

-

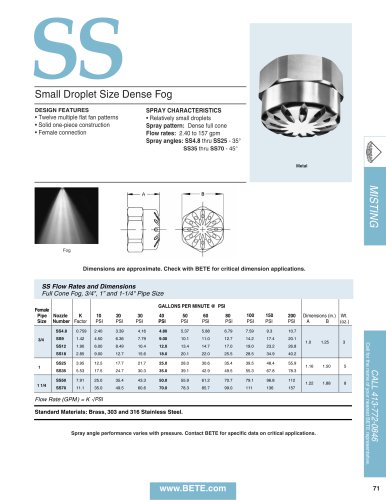

SS

1 Pages

-

UltiMist

1 Pages

-

L

1 Pages

-

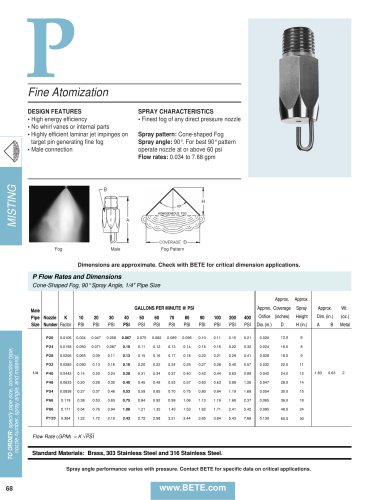

p

1 Pages

-

PJ

1 Pages

-

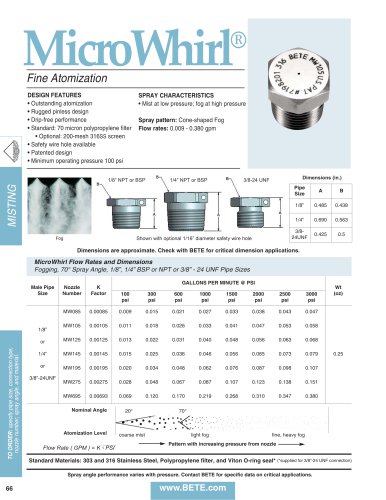

MicroWhirl

1 Pages

-

SPN

1 Pages

-

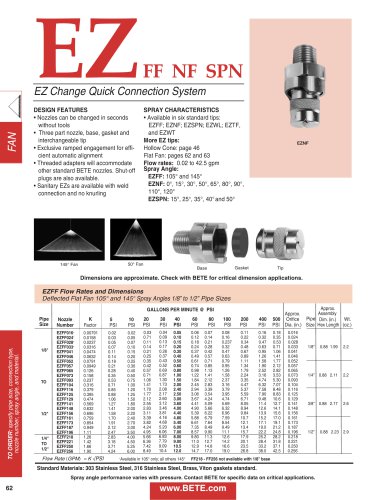

EZ FF NF SPN

2 Pages

-

FF

2 Pages

-

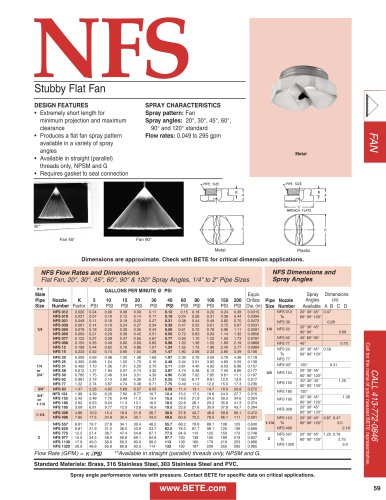

nfs

1 Pages

-

NFD

1 Pages

-

NF

1 Pages

-

NFV

1 Pages

-

HydroPulse

4 Pages

-

BJ

2 Pages

-

Spillback

2 Pages

-

THW

2 Pages

-

NCJ

1 Pages

-

TH

2 Pages

-

WTX

2 Pages

-

WT

2 Pages

-

TC

1 Pages

-

NCFL

1 Pages

-

NCK

1 Pages

-

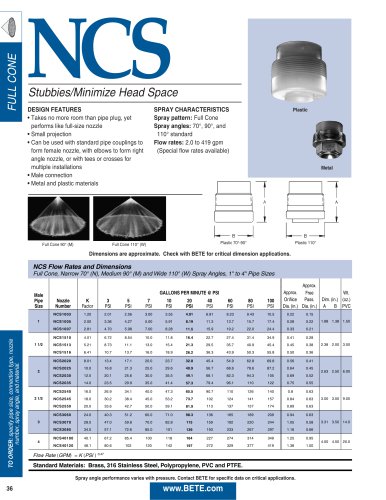

NCS

1 Pages

-

NC

2 Pages

-

SF

3 Pages

-

EZFF

2 Pages

-

WTZ

1 Pages

-

CW

2 Pages

-

WL

1 Pages

-

STXP

1 Pages

-

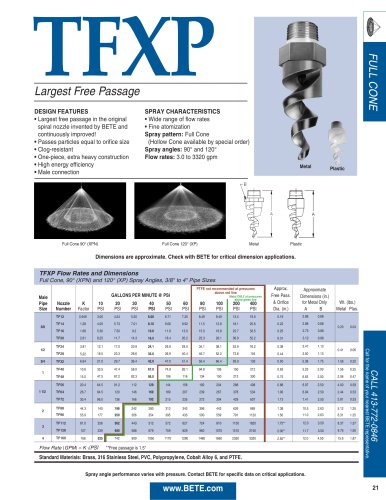

TFXP

1 Pages

-

TF

2 Pages

-

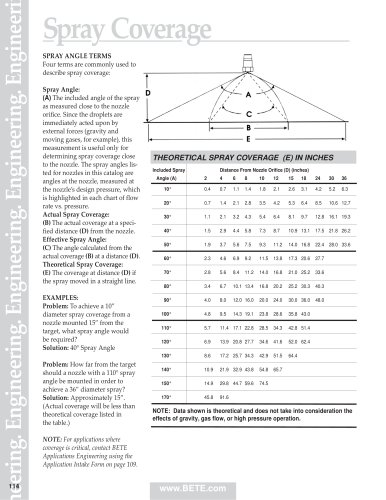

Spray Coverage

1 Pages

-

Bete accessories

1 Pages

-

MATERIALS

1 Pages

-

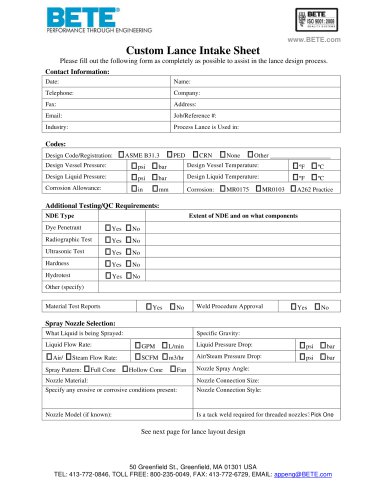

Custom Lance Intake Sheet

2 Pages

-

Pollution Control

8 Pages

-

Food Industry

8 Pages

-

Fire Protection

8 Pages

-

DUR O LOK®

6 Pages

-

Spray Nozzle Catalogs

127 Pages

-

MaxiPass ® L

1 Pages

-

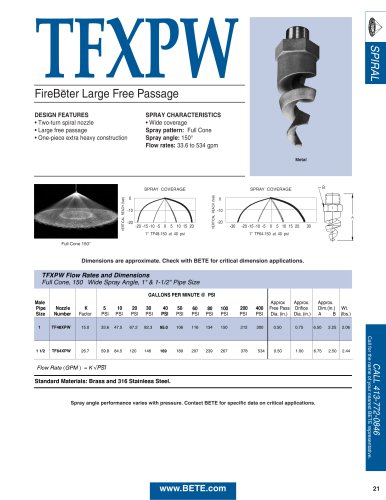

TFXPW

1 Pages

-

N

2 Pages

-

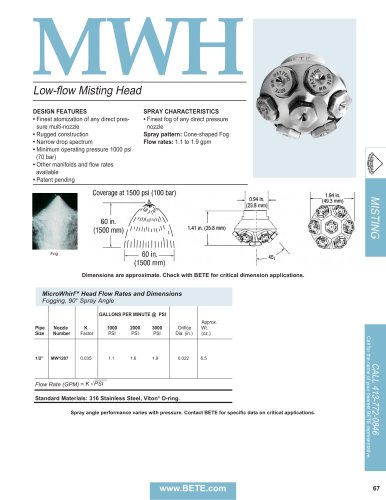

MicroWhirlTM Head (MWH)

1 Pages

-

MaxiPassTM Low Flow (MPL)

1 Pages

-

MaxiPassTM (MP)

2 Pages

-

LP

1 Pages

-

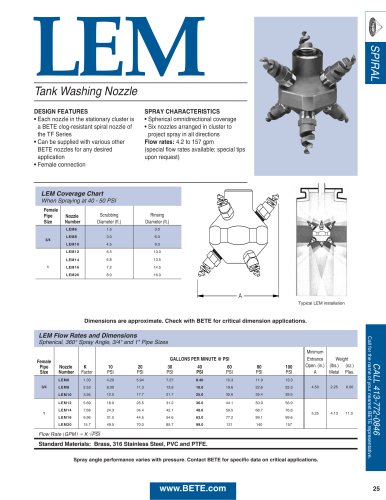

LEM

1 Pages

-

IS

1 Pages

-

FluidBed

1 Pages

-

Spray Drying

11 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

TD/TD-K

4 Pages

-

FINZTM

1 Pages

-

SpiralAirTM

2 Pages

-

SC

2 Pages

Archived catalogs

-

N Fire Protection

2 Pages

-

TW

1 Pages

-

Spray dry manual

25 Pages