Website:

BETE

Website:

BETE

Catalog excerpts

NOZZLES FOR BOTTLE, DRUM, AND TANK WASHING Manual No. 105.2TW

Open the catalog to page 1

Choosing the Best Nozzles Important Design Features to Consider When Choosing the Best Nozzle for Your Washing Needs Adequate coverage and effective scrubbing are of prime importance in bottle, drum, and tank washing. Choosing from the variety of nozzles, both stationary and rotary can be confusing. In selecting BETE nozzles you should consider the following vessel characteristics and nozzle design criteria: size and shape of vessel to be cleaned; vessel opening; type of material to be removed; and spray coverage. Size and Shape of Vessel to be Cleaned BETE’s tank washing nozzles can be...

Open the catalog to page 2

for Bottle, Drum and Tank Washing Type of Material to be Removed Another concern in choosing the correct nozzle should be the viscosity and the tenacity of the material to be removed within the vessel. Sticky viscous substances require greater scrubbing. This is most often accomplished with high impact sprays.* For high impact scrubbing a rotary nozzle, the RTW or ScrubMateTM, will provide greater cleaning power if the vessel is not too large (see chart, on right). Less viscous material can be removed by washing and rinsing with lower impact, finer sprays. Liquids such as: fruit juices,...

Open the catalog to page 3

Stationary Tank Washing Nozzles cooling and fume absorption • Best rinsing performance moderate sized vessels CLUMP series • Symmetrical spray make them more suited to short tanks, full 360° washing • Very large free passage • Rinsing of containers under used in narrow- necked container rinsing omni- directional spray. The spray is relatively low impact, with individual spray cones producing good rinsing in tar- geted areas. Typically the LEMs perform This series, as well as the CLUMP series, creates sym- metrical spray, "a wet puff- ball," and is best suited to tanks whose width exceeds...

Open the catalog to page 4

HydroWhirl™ Orbitor tank cleaning machine is ideal for high impact cleaning The HydroWhirl™ Orbitor is a versatile tank cleaning machine designed to meet the high standards required in the food, brewing, beverage, dairy, and chemical industries combining high performance cleaning efficiency with extended operating life and reduced life cycle costs. Advantages of the HydroWhirl Orbitor tank cleaning machine. • The HydroWhirl Orbitor can be stripped, maintained, and rebuilt in less than 15 minutes. • The HydroWhirl Orbitor is self cleaning and self • Enhanced external cleaning with dedicated...

Open the catalog to page 5

Hydro Whirl Orbitar High Impact Rotary Tank Cleaning Machine DESIGN FEATURES • Reduced operating costs • Minimum moving parts = reduced life- cycle costs • Self cleaning; self lubricating = no process contamination • High-impact jets; orbital wash pattern = high efficiency cleaning • Compact design • 2 or 4 nozzle configurations = wash pattern variable up to super intense • Male or female connections SPRAY CHARACTERISTICS • Variable cycle times • High impact cleaning Bushings/Seals: Carbon Filled PTFE Minimum opening size is 125 mm (5") standard-capacity model. spray pattern spray pattern...

Open the catalog to page 6

HydroWhirl Poseidon spray nozzles for quick, efficient tank cleaning The HydroWhirl Poseidon tank-washing nozzle directs the cleaning water through a rotating head at the tip of the spray assembly. This produces a slow-moving, high-impact spray action against internal surfaces of the tank. The HydroWhirl Poseidon nozzle head uses impact and repetition to quickly break up and wash away contamination. The combination of the spray pattern and slow rotation of the HydroWhirl Poseidon tank-washing nozzle is especially effective at removing scum rings or tougher, stuck-on material. Poseidon™...

Open the catalog to page 7

Tank Washing - PTFE Spray Nozzle DESIGN FEATURES • Cleans more quickly, and uses less water and lower pressure than static tank washers • PTFE construction: - Ideal for harsh chemical environments - Corrosion resistant • Three connections: pipe, tube, or DIN clip-on. Threaded connections available upon request. • Made from FDA-approved materials for use in SPRAY CHARACTERISTICS • Slow spinning, longer spray dwell time on the target surface increases impact over conventional rotating designs spray pattern Minimum Tank Opening: Threaded connections available upon request Dimensions are...

Open the catalog to page 8

Tank Washing - PTFE Spray Nozzle Flow Rate vs Pressure Flow Rate vs Pressure Threaded connections may restrict the flow. Contact BETE for more information.

Open the catalog to page 9

slotted rotating quick, efficient tank The HydroWhirl™S nozzle directs the cleaning water through a rotating w head at the tip of the spray assembly. This produces a vigorous moving spray action against all areas of the walls of a tank. The spray pattern from the HydroWhirl S head uses impact and repetition to quickly wash the tank. This spray pattern is especially effective at breaking up and removing contaminants. rotary spray nozzle. • Cleans more quickly, but uses less water and lower pressure than static tank washers • Lower flow and pressure mean smaller pump size resulting in lower...

Open the catalog to page 10

Tank Washing - Slotted Spray Nozzle DESIGN FEATURES • Cleans more quickly, but uses less water and lower pressure than static tank washers • Surface finish ideal for sanitary applications • Orbital welded design - durable • Stainless steel construction - corrosion • Three connections - threaded, clip-on • Made from FDA approved materials for SPRAY CHARACTERISTICS • Self-cleaning bearings • Vigorous moving spray action • Complete 360° omnidirectional coverage Dimensions are approximate. Check with BETE for critical dimension applications. Not recommended for applications over 60 psi....

Open the catalog to page 11

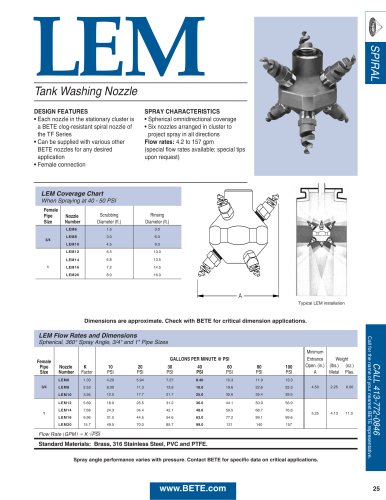

Tank Washing Nozzle DESIGN FEATURES • Each nozzle in the stationary cluster is a BETE clog-resistant spiral nozzle of • Can be supplied with various other BETE nozzles for any desired • Female connection SPRAY CHARACTERISTICS • Spherical omni-directional coverage • Six nozzles arranged in cluster to pro- ject spray in all directions (special flow rates available, special tips upon request) LEM Flow Rates and Dimensions Spherical, 360° Spray Angle, 3/4" and 1 " Pipe Sizes, BSP or NPT Flow Rate (GPM) =KiPSI Flow Rate (l/min) =Kybar Standard Materials: Brass, 316 Stainless Steel, PVC and PTFE.

Open the catalog to page 12All BETE catalogs and technical brochures

-

WL metric

1 Pages

-

PJ metric

1 Pages

-

NF

1 Pages

-

SpiralAir

2 Pages

-

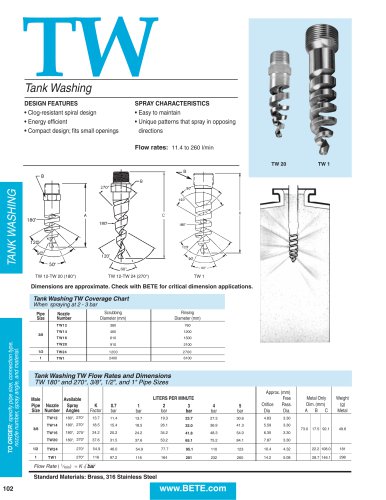

TW metric

1 Pages

-

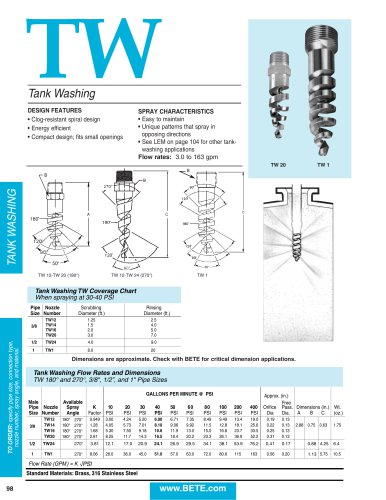

TW

1 Pages

-

AFF metric

1 Pages

-

TF10-170

1 Pages

-

TF24

1 Pages

-

TF FM Approved

1 Pages

-

TF metric

1 Pages

-

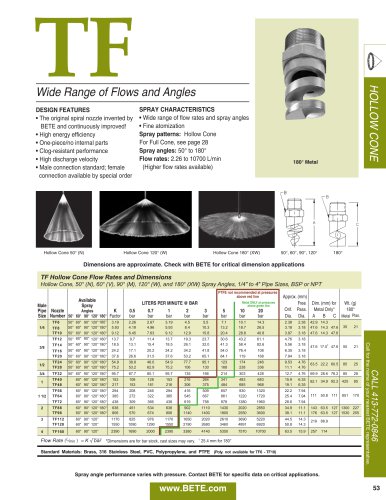

TF

1 Pages

-

TF

1 Pages

-

MaxiPass®

2 Pages

-

HydroClaw®

2 Pages

-

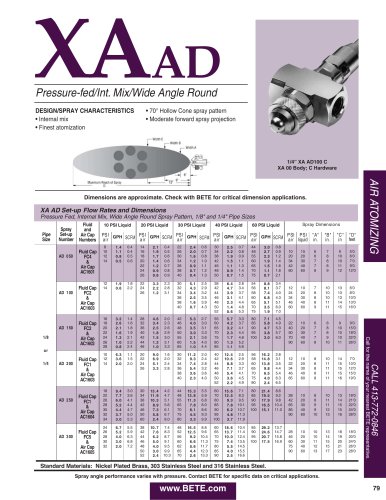

XAAD

1 Pages

-

ST

1 Pages

-

XA Components & Options

1 Pages

-

Engineering Information

9 Pages

-

Custom In-House Fabrications

2 Pages

-

BETE Spray Nozzle Catalog

134 Pages

-

Line Card

2 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

BETE Metric Catalog

132 Pages

-

NFH

1 Pages

-

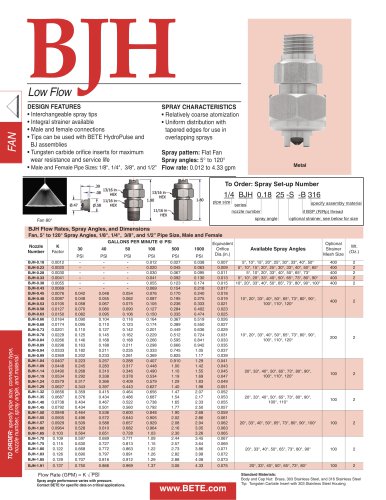

BJH

1 Pages

-

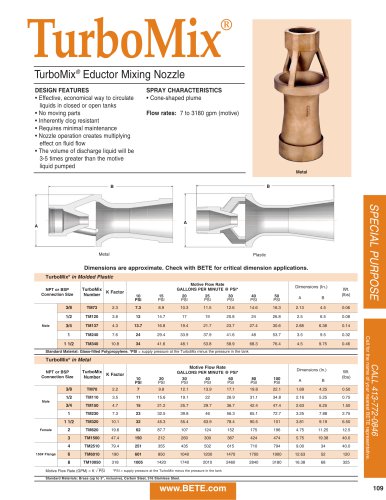

TurboMix

1 Pages

-

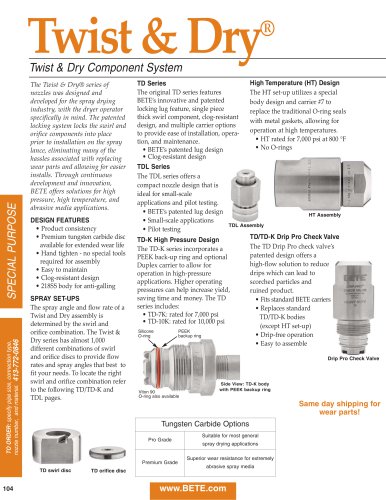

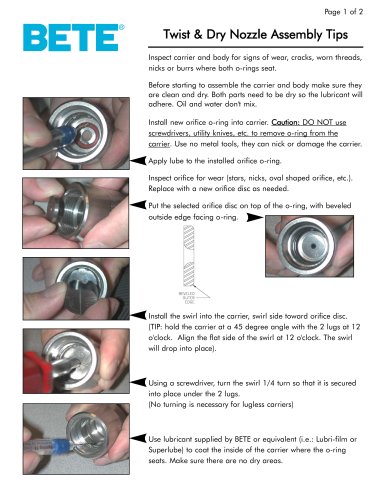

Twist & Dry

5 Pages

-

TF29

1 Pages

-

N fire protection

1 Pages

-

AFF

1 Pages

-

LEM

1 Pages

-

CLUMP

1 Pages

-

HydroWhirl Orbitor

2 Pages

-

HydroWhirl ® Poseidon

1 Pages

-

HydroWhirl S

1 Pages

-

SpiralAir

2 Pages

-

SAM

2 Pages

-

XA Accessories

4 Pages

-

XA

7 Pages

-

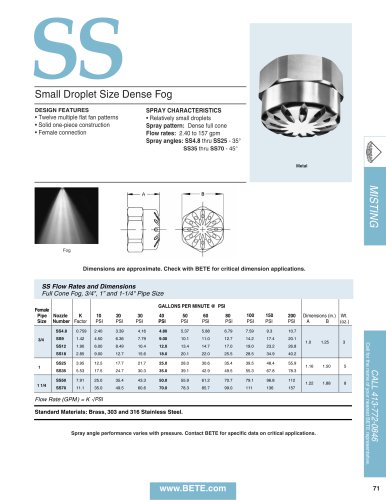

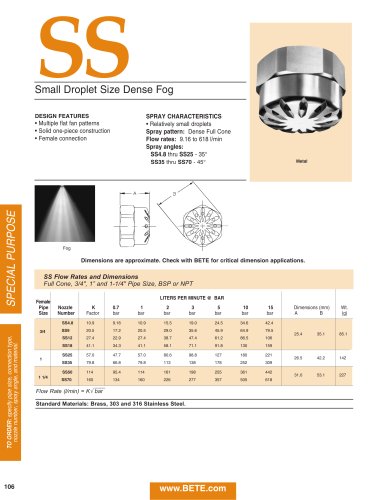

SS

1 Pages

-

UltiMist

1 Pages

-

L

1 Pages

-

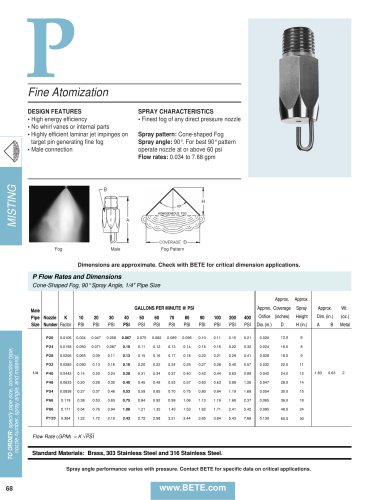

p

1 Pages

-

PJ

1 Pages

-

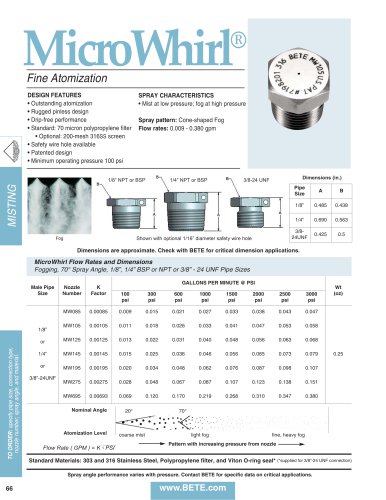

MicroWhirl

1 Pages

-

SPN

1 Pages

-

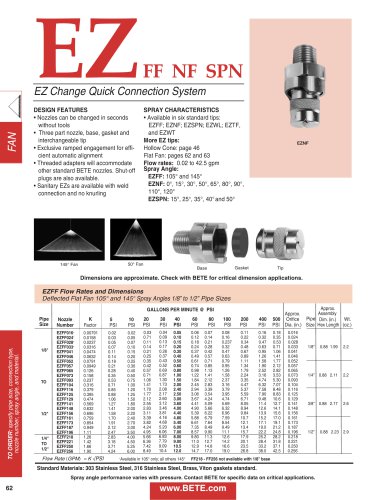

EZ FF NF SPN

2 Pages

-

FF

2 Pages

-

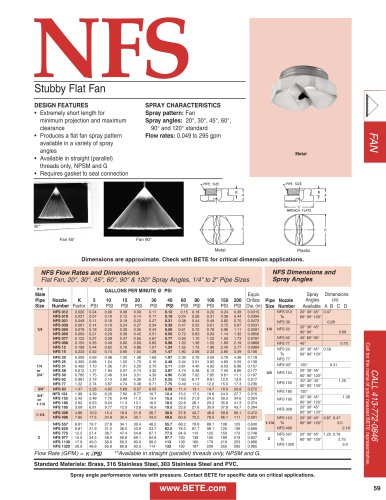

nfs

1 Pages

-

NFD

1 Pages

-

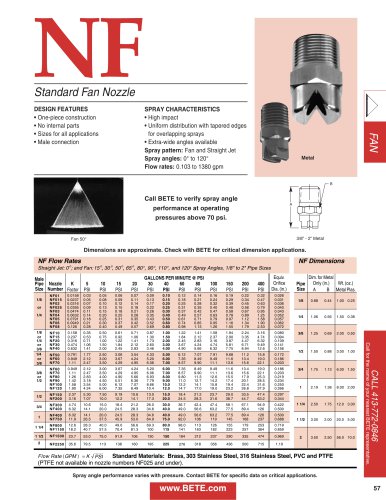

NF

1 Pages

-

NFV

1 Pages

-

HydroPulse

4 Pages

-

BJ

2 Pages

-

Spillback

2 Pages

-

THW

2 Pages

-

NCJ

1 Pages

-

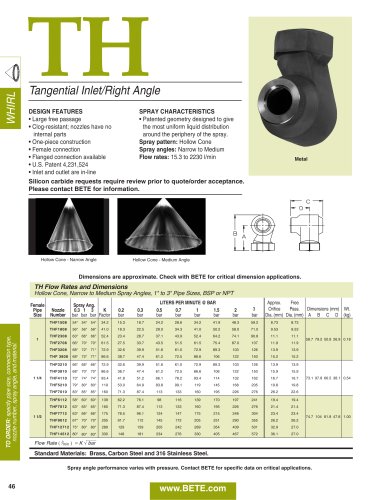

TH

2 Pages

-

WTX

2 Pages

-

WT

2 Pages

-

TC

1 Pages

-

NCFL

1 Pages

-

NCK

1 Pages

-

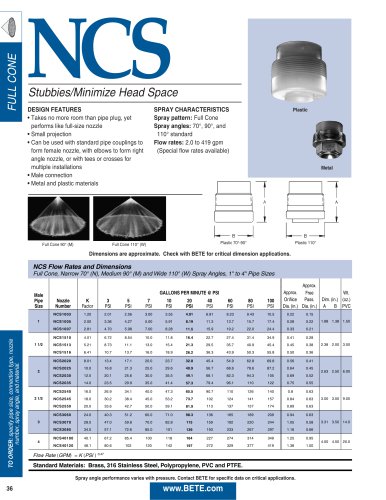

NCS

1 Pages

-

NC

2 Pages

-

SF

3 Pages

-

EZFF

2 Pages

-

WTZ

1 Pages

-

CW

2 Pages

-

WL

1 Pages

-

STXP

1 Pages

-

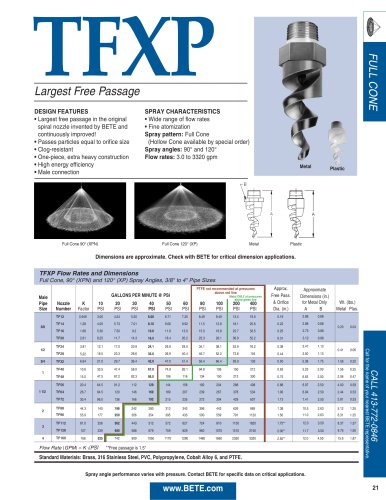

TFXP

1 Pages

-

TF

2 Pages

-

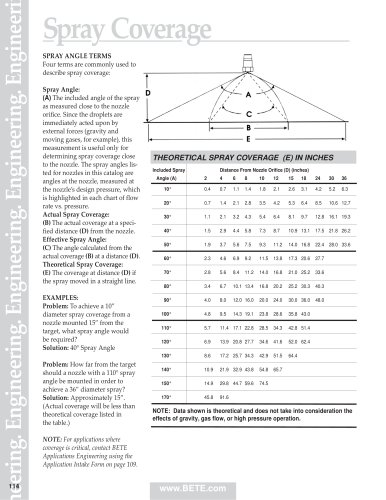

Spray Coverage

1 Pages

-

Bete accessories

1 Pages

-

MATERIALS

1 Pages

-

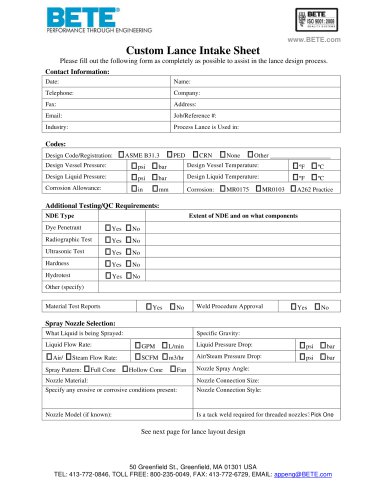

Custom Lance Intake Sheet

2 Pages

-

Pollution Control

8 Pages

-

Food Industry

8 Pages

-

Fire Protection

8 Pages

-

DUR O LOK®

6 Pages

-

Chemical Processing

8 Pages

-

Spray Nozzle Catalogs

127 Pages

-

MaxiPass ® L

1 Pages

-

TFXPW

1 Pages

-

N

2 Pages

-

MicroWhirlTM Head (MWH)

1 Pages

-

MaxiPassTM Low Flow (MPL)

1 Pages

-

MaxiPassTM (MP)

2 Pages

-

LP

1 Pages

-

LEM

1 Pages

-

IS

1 Pages

-

FluidBed

1 Pages

-

Spray Drying

11 Pages

-

TD/TD-K

4 Pages

-

FINZTM

1 Pages

-

SpiralAirTM

2 Pages

-

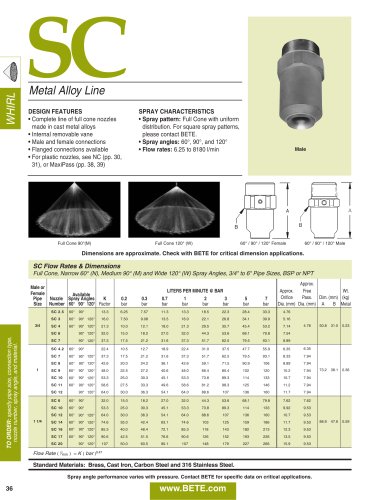

SC

2 Pages

Archived catalogs

-

N Fire Protection

2 Pages

-

TW

1 Pages

-

Spray dry manual

25 Pages