Website:

BESTACT SOLUTIONS INC.

Website:

BESTACT SOLUTIONS INC.

Group: YASKAWA

Catalog excerpts

Carry Current Contact Capacity Insulation Resistance

Open the catalog to page 1

• What is the High-Power Reed Switch “Bestact®”? • Features of “Bestact®” contact • Examples of products incorporating Bestact® and its advantages • Examples of inductive load equipment that can be controlled by Bestact® • Performance comparison between the relay with other companies’ equivalent products • Differences between Bestact® and general reed switches YASKAWA © 2025 BESTACT SOLUTIONS I

Open the catalog to page 2

What is the High-Power Reed Switch “Bestact®*"? Among reed switches, Bestact® is classified as a heavy-duty reed switch and is defined in the IEC standard as follows. “Reed switch, in which greater switching capacity is achieved.” “Blades having additional contact tips or a contact tip and spring which separate the magnetic path and electric path are typical examples of techniques to increase switching capacity.” From IEC 62246-1-1 High-Power Reed Switch Backstop Mechanism Return Spring Magnetic Members Inert Gas Contact Parts Glass Tube Contact Chip High-performance contact due to unique...

Open the catalog to page 3

Features of “Bestact®” contact The Contact that Enables both High Power and Small Size High Carry Current: 13A ・Enables 13A Carry Current, the largest value in dry reed switches, 2 to 5 times greater* than competitors. ・Even if several contacts are used to carry more than 10A, Bestact® allows you to use only one Bestact® instead, enabling you to downsize your devices and reduce costs. Large Contact Capacity and High Insulation Resistance in a Small Size ・Maximum Contact capacity of 150W, insulation resistance of 10¹³Ω, and approximately 18% smaller* than competing products with the same...

Open the catalog to page 4

Resistive Switching voltage 300 Load Switching current 3 Switching current Carry current Breakdown voltage Contact resistance Insulation resistance Capacitance Electrical life Pull in range Drop out Operate time Release time Vibration Shock Operate temperature Storage temperature Lead tensile strength Soldering temperature Please inquire as it depends on load. Test coil is of 3000 turns, 33.5mm long, 10.5mm I.O. with 0.2mm dia. wire Please contact us for quotes, free samples and detailed specifications, etc. Let us know if you have any requests for high withstand voltage type or inductive...

Open the catalog to page 5

RoHS COMPLIANT RoHS COMPLIANT Appearance YASKAWA © 2025 BESTACT SOLUTIONS INC.

Open the catalog to page 6

Examples of products incorporating Bestact® and its advantages Power Relays • Large contact capacity and high insulation resistance in a small size. • Enables over 10A carry current in a small size and lower cost. • Simplifies the circuit by switching inductive loads without protection circuits. • Long life even with inductive load switching reduces maintenance costs. • Simplifies the circuit by switching inductive loads without protection circuits. • Long life even with inductive load switching reduces maintenance costs. • Can also be used for micro loads. • Resistant to adverse...

Open the catalog to page 7

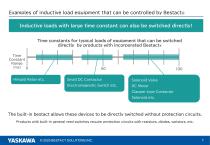

Examples of inductive load equipment that can be controlled by Bestact® Inductive loads with large time constant can also be switched directly! Time constants for typical loads of equipment that can be switched directly by products with incorporated Bestact® Time Constant Range (ms) 0 Solenoid Valve DC Motor Clapper type Contactor Solenoid etc. The built-in bestact allows these devices to be directly switched without protection circuits. Products with built-in general reed switches require protection circuits with resistors, diodes, varistors, etc.

Open the catalog to page 8

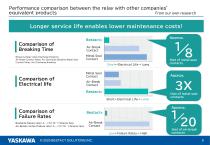

Performance comparison between the relay with other companies’ From our own research equivalent products Longer service life enables lower maintenance costs! Approx. Comparison of Breaking Time Bestact® Relay: Glow Discharge Breaking Air-Break Contact Relay: Arc Discharge Breaking Metal Seal Contact Relay: Arc Discharge Breaking Comparison of Electrical life Air-Break Contact Metal Seal Contact Short←Electrical Life→ Long Metal Seal Contact Air-Break Contact Bestact® Short←Electrical Life→ Long Comparison of Failure Rates Bestact® failure rate=λ₆₀=5×10⁻⁹(/time)or less Air-Break contact...

Open the catalog to page 9

Differences between Bestact® and general reed switches Separation of magnetic contact part and electric contact part enables stable operation! General Reed Switch Magnetic and electrical circuits are same Magnetic and electrical circuits are separated Magnetic Circuit Electrical Circuit

Open the catalog to page 10

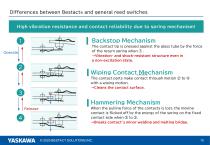

Differences between Bestact® and general reed switches High vibration resistance and contact reliability due to spring mechanism! YASKAWA © 2025 BESTACT SOLUTIONS INC. | Backstop Mechanism The contact tip is pressed against the glass tube by the force of the return spring when ® . -^Vibration- and shock-resistant structure even in a non-excitation state. The contact parts make contact through motion ® to ® with a wiping motion. ^Cleans the contact surface. When the pulling force of the contacts is lost, the moving contact is flicked off by the energy of the spring on the fixed contact side...

Open the catalog to page 11

The Contact that Enables both High Power and Small Size Worth a try and you will surely feel its quality. Contact us for quotes and detailed specifications, etc. https://www.bestact.co.jp/gl/contact Available for online purchase from around the world.

Open the catalog to page 12All BESTACT SOLUTIONS INC. catalogs and technical brochures

-

Medium-power reed switch

2 Pages

-

High-power reed switch

2 Pages

-

Railway with Bestact

12 Pages

-

Bestact Digest

5 Pages

-

Bestact Technical catalogue

94 Pages