Catalog excerpts

MEASUREMENT SOLUTIONS FOR THE SUGAR INDUSTRY Optimize your production process with improved quality and efficiency

Open the catalog to page 1

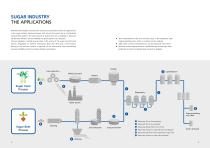

SUGAR INDUSTRY THE APPLICATIONS Berthold Technologies measurement solutions are perfectly tailored for applications in the sugar industry. Renowned sugar mills all over the world rely on the Berthold measurement systems. The vast amounts of systems that are successfully in operation are the best reference for the reliability and good quality of our products. They are applied in multiple process steps in the course of the sugar manufacturing process. Regardless of whether information about the °Brix value, concentration, density or the moisture content is required, all our instruments show...

Open the catalog to page 2

MEASURING °BRIX IN THE EVAPORATION The extracted thin juice passes through multiple effect evaporators which boil off the water and produce syrup known as thick juice. The thick juice which is produced can either be used for immediate crystallization or be stored in large storage tanks. The evaporation process increases the solids content of the juice from 16% to 65%. Typically, the water is boiled off in a number of evaporator vessels. After each stage of evaporation the °Brix content of the sugar juice is measured. The microwave based systems from Berthold provide real-time information on...

Open the catalog to page 3

MEASURING °BRIX IN THE CRYSTALLIZER The thick juice is heated in the crystallization process under vacuum conditions. When a certain concentration is reached, the juice is seeded with tiny sugar crystals to promote the growth of uniform crystals. With the microwave measuring systems from Berthold, the juice concentration (°Brix) is monitored throughout the crystallization process and a precise determination of the seeding point can be determined. The systems are applied in all crystallization stages. Due to the robust device and the superior sensor flushing, the measuring systems have...

Open the catalog to page 4

MEASURING DENSITY OF MILK OF LIME IN THE PURIFICATION PROCESS After extracting the raw juice from sugar beets, the juice passes through a purification stage called carbonation. In this purification process milk of lime is added as a reactant. The quality of the milk of lime has to be monitored in several stages to achieve better purification results and an optimized process. The Berthold measurement system based on microwave technology helps sugar mills worldwide to control the concentration of milk of lime by an online measurement – either in the pipeline or in process tanks like...

Open the catalog to page 5

MEASURING MOISTURE IN SUGAR BEET SLICES AND BAGASSE After sugar extraction, bagasse or beet pulp remains as a by-product. They are further processed either as a source of energy to generate power and heat or to produce feed for dairy cattle and fatlings. Both bagasse and beet pulp contain a certain amount of water, which needs to be measured in order to ensure continuity and high quality of the downstream processes. The Berthold microwave systems are applied to determine moisture online and noncontacting, on conveyor belts or chutes. Thus, the customer receives representative, in-situ...

Open the catalog to page 6

MEASURING THE MASS FLOW RATE OF SUGAR BEETS OR CANE MEASURING MOISTURE IN SUGAR CUBE PRODUCTION The ratio between raw material feed and additives needs to be balanced to ensure smooth and efficient production process. Therefore, the amount of sugar beets or sugar cane is measured as it enters the production site. Typically, a radiometric belt weigher is installed prior to the washing plants. It measures the mass flow of the sugar beets / sugar cane very reliably by using non-contacting, non-intrusive radiometric technology. A further application is found directly after unloading of the...

Open the catalog to page 7

THE BERTHOLD MICROWAVE SYSTEM FOR THE SUGAR INDUSTRY Horn Antenna measurement covers the entire pipe cross-section ■ ominal sizes from DN 50 to DN 150 N ■ ommon connection variants C ■ eplaceable antennas R ■ HEDG E certifictation for the contact with food according to the regulation (EC) No 1935/2004 non-intrusive sensor for conveyor belt and chute installations ■ Optimal focussing of the microwaves ■ Robust design ■ High shock and vibration resistance ■ Easy to install on existing lines, without process downtime ■ No wear and tear Container Probe ■ ensor S for installation on tanks and...

Open the catalog to page 8

Berthold Technologies stands for excellent know-how, high quality and reliability. The customer is always the focus of our solution. We know our business! Using our varied product portfolio, our enormous specialized knowledge and extensive experience, we develop suitable solutions together with our customers for new, individual measurement tasks in a wide variety of industries and applications. Berthold Technologies is specialised in radiometric process measurements for 70 years. More than 30 years ago Berthold expanded their portfolio and introduced microwave technology to the sugar...

Open the catalog to page 9All Berthold Technologies Process Control catalogs and technical brochures

-

Density measurement

5 Pages

-

Continuous level measurement

5 Pages

-

Retrofit

3 Pages

-

Article "Made to measure"

3 Pages

-

Moisture in pasta production

3 Pages

-

Glass level measurement

3 Pages

-

Mould level measurement

4 Pages

-

LB 475 Fracturing system

3 Pages

-

Multiphase level measurement

7 Pages

-

Produkt InlineSENS

4 Pages

-

Industry Sugar

9 Pages

-

LB472 Bulk Flow Meter

12 Pages

-

MEVIS

4 Pages

-

NUMo - LB 134 UMo II

2 Pages

-

Radiation Protection Instruments

12 Pages

-

Micro-Polar

16 Pages

-

DuoSeries Detectors LB 4700

2 Pages

-

Rod Source Shielding

4 Pages

-

Safety Source Capsule SSC

2 Pages

-

Level Switch LB 471

6 Pages