Catalog excerpts

Serving an entire spectrum of mechanical drive applications from food, energy, mining and metal; to automotive, aerospace and marine propulsion, we are here to make a positive difference to the supply of drive solutions. Series A Worm Gear units and geared motors in single & double reduction types Series BD Screwjack worm gear unit Series BS Worm gear unit Series C Right angle drive helical worm geared motors & reducers Series F Parallel shaft helical geared motors & reducers Series G Helical parallel shaft & bevel helical right angle drive gear units Series H Large helical parallel shaft &...

Open the catalog to page 2

Total compliance with the ATEX Directive safeguarding the use of industrial equipment in potentially explosive atmospheres is assured for users of our geared products. Certification is available for standard gearboxes and geared motors with badging displaying the ATEX zone, name and location of the manufacturer, designation of series or type, serial number, year of manufacture, Ex symbol and equipment group/category. ATEX directive 94/9/EC (also known as ATEX 95 or ATEX 100A) enforced in all EC member states. Compliance is compulsory for designers, manufacturers or suppliers of electrical...

Open the catalog to page 3

*HQHUDO 'HVFULSWLRQ BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB /XEULFDWLRQ BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

Open the catalog to page 5

GENERAL DESCRIPTION The range of Series P Planetary units has 10 sizes with ratio coverage from 3.6:1 to 3200:1 providing an efficient and compact drive solution to meet power requirements up to 90kW and 65000 Nm torque capacity. The range takes advantage of many years of accumulated design expertise, together with the use of high quality materials and components, the end result is a high quality series of planetary gear reducers and geared motors offering a high load carrying capacity, high efficiency, quiet running and reliable drive solution. Standard unit versions available: Parallel...

Open the catalog to page 6

Frl Input Shaft Radial Load Capacity (N) fs Starting Frequency Factor i Actual Transmission Ratio = nl M2 Output Torque (Nm) = Pe x 9550 n2 n2*h Output Speed (rpm) x Operating Hours Pt Thermal Rating (when t = 20 °C) fm Mechanical Service Factor Fr2 Output Shaft Radial Load Capacity (N) iN Nominal Transmission Ratio T2 Rated Output Torque (Nm) T2a Required Rated Torque (Nm) = M2 x f h Lifetime (hours) fw Thermal Rating Modifying Factor Thermal Modifying Factor fw Ambient Temperature Starts (or Stops) per Hour

Open the catalog to page 7

Load Classification U Uniform Load M Moderate Shock Load H Heavy Shock Load t Consult our Engineers Dredgers Conveyors Cutter head drive Pumps Screen Drive Stackers Winches Machine Tools Bending roll Punch press Notching press Plate planer Other machine tools Main drive Aux drive Agitators Pure liquids Liquids and solids Liquids variable density Blowers Centrifugal Lobe Vane Elevators Bucket - Uniform load Bucket - Heavy load Bucket - Continuous Centrifugal discharge Escalators Freight Gravity discharge Passenger Lifts Metal mills U Carriage / Main drive M Draw bench Brewing & distilling...

Open the catalog to page 8

1. Determine Service Factor - f Refer to: Mechanical Service Factor Table fm Starting Frequency Factor Table fs Starts (or Stops) per Hour SELECTION EXAMPLE Absorbed Power (Pe) = 4.5 kW nl = 1450 rpm, n2 = 22 rpm Required Ratio (/) = 1450 = 66:1 22 Ambient Temperature (t) = 30°C Moderate Shock Loading -1 start / hour 8 hours / day - Continuous Operation Expected Service Life 20,000 hours Use the n2*h column that is both nearest and greater than the required n2*h value. The required n2*h = 400,000 hours - The nearest n2*h column is 500,000 hours Select the nearest gear unit with a rated...

Open the catalog to page 9

SELECTION EXAMPLE MOTORISED UNIT Parallell Unit Type PL Absorbed Power (Pe) = 1.3 kW Motor Power = 1.5 kW nl = 1450 rpm, n2 = 16.0 rpm Required Ratio (/) = 1450 = 90.6:1 16 Ambient Temperature (t) = 40°C Moderate Shock Loading -1 start / hour 1. Determine Service Factor - f Refer to: Mechanical Service Factor Table fm Starting Frequency Factor Table fs Select the Gear Unit Refer to: Motorised Selection Tables (Select a motor power greater than the absorbed power) Unit Designation Motor Frame Unit selected: PL0130 Actual Ratio i = 93.77:1 i N = 90 Check the Required Service Factor f (1.25)...

Open the catalog to page 10

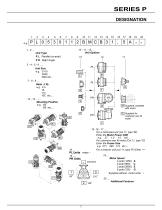

For a reducer unit (col 11, type R) Enter — Motor Speed 4 pole (1450) A 6 pole (960) C 2 pole (2900) E 8 pole (725) G Supplied without motor enter - Additional Features

Open the catalog to page 11

NOMINAL TORQUE

Open the catalog to page 12

NOMINAL TORQUE

Open the catalog to page 13

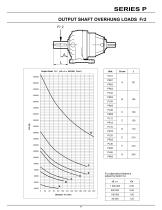

For alternative lifetime's adjust by factor Co n2 x h

Open the catalog to page 15

_SERIES PPL MOTORISED RATINGS Unit Designation Motor Frame PT(kW) PT (kW) Type B Type F PL01 PL01 PL01

Open the catalog to page 38

_SERIES PPL MOTORISED RATINGS Unit Designation PL034016C -M--- .18 PL034018C -M--- .18 PL034020C -M--- .18 PL034022C -M--- .18 Motor Frame PT(kW) PT (kW) Type B Type F 63 7.0 6.8

Open the catalog to page 39

_SERIES PPL MOTORISED RATINGS Unit Designation PL124018C - M — .25 PL124020C - M — .25 PL124025C - M — .25 Motor Frame PT(kW) Type B

Open the catalog to page 40

_SERIES PPL MOTORISED RATINGS Unit Designation

Open the catalog to page 41

Motor Frame PT(kW) Type B PT (kW)

Open the catalog to page 42

_SERIES PPL MOTORISED RATINGS Unit Designaltion PL054010C -M--- .75 PL054011C -M--- .75 PL054012C -M--- .75 PL054014C -M--- .75 Motor Frame PT(kW) PT (kW) Type B Type F Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A M--- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75 A Mt-t-t- .75...

Open the catalog to page 43

_SERIES P PL MOTORISED RATINGS Unit Designation Motor

Open the catalog to page 46

Frame PT(kW)

Open the catalog to page 47

_SERIES P PL MOTORISED RATINGS Unit Designaltion Motor

Open the catalog to page 48

_SERIES P PL MOTORISED RATINGS Unit Designation PL1230250 -M--- 3.0 PL1230280 -M--- 3.0 PL1230360 -M--- 3.0 Motor Frame PT(kW)

Open the catalog to page 49

_SERIES PPL MOTORISED RATINGS Unit Designation PL0330112 -M--- 4.0 PL0330125 -M--- 4.0 PL0330140 -M--- 4.0 PL0330160 -M--- 4.0 Motor Frame PT(kW) PT (kW) Type B Type F

Open the catalog to page 50All BENZLERS catalogs and technical brochures

-

Series X Flexible Couplings

36 Pages

-

SERIES M

94 Pages

-

Roloid Gear Pump

17 Pages

-

Benzlers Screw Jacks

69 Pages

-

Series J Shaft Mounted Gearbox

73 Pages

-

Series P

4 Pages

-

Series E

4 Pages

-

Compact Motor

4 Pages

-

Series J

4 Pages

-

Series G flyer

4 Pages

-

Benzlers Product Brochure

8 Pages

-

BR Series BS

60 Pages

-

BR Cone Ring Couplings

16 Pages

-

BR Series X Couplings

36 Pages

-

BR Series H

123 Pages

-

BR Series G

71 Pages

-

BR Compact Motors

64 Pages

-

BR Series M

120 Pages

-

BR Series C

106 Pages

-

BR Series K

90 Pages

-

BR Series F

117 Pages

-

Series BD Screw Jacks

58 Pages

-

Elflex Flexible Couplings

8 Pages

-

Elign Gear Couplings

17 Pages

-

Series X

64 Pages

-

Series G

71 Pages

-

Geared Motor Series M

120 Pages

-

Geared Motor Series C

120 Pages

-

Geared Motor Series K

90 Pages

-

Geared Motor Series F

119 Pages