Catalog excerpts

Series M Helical In-Line Technical Up to - 120 HP / 97,500 lb.in Geared Motors CM-2.00US1211

Open the catalog to page 1

PRODUCTS IN THE RANGE Serving an entire spectrum of mechanical drive applications from food, energy, mining and metal; to automotive, aerospace and marine propulsion, we are here to make a positive difference to the supply of drive solutions. Series A Worm Gear units and geared motors in single & double reduction types Series BD Screwjack worm gear unit Series BS Worm gear unit Series C Right angle drive helical worm geared motors & reducers Series F Parallel angle helical bevel helical geared motors & reducers Series G Helical parallel shaft & bevel helical right angle drive gear units...

Open the catalog to page 2

SERIES M CONTENTS General Description Unit Designations Explanation and use of Ratings and Service Factors Selection Procedure For Motorized Units Output Options MOTORIZED Motor Details Motorized Backstop Module Reduction Ratings Thermal Power Ratings Reducer Backstop Module

Open the catalog to page 3

SERIES M GENERAL DESCRIPTION Series M inline geared motors and reducers provide a accumulated design expertise, together with the use result is a series of speed reducing and geared mo- mounted motorized - Base Mounted - B5 (D) Flange Mounted M - Motorized with IEC standard motor mounted motorized mounted motorized * Design Features Include quired. motors. major manufacturers. * fan. As improvements in design are being made continu- in detail and drawings and capacities are subject to sent on request. 1

Open the catalog to page 4

SERIES M UNIT DESIGNATIONS Geared Motor Power Mounting Position Output Shaft Unit Version Revision Version Motor Codes 20 - Additional Gearbox Features 19 - Additional Motor Features 4 - No of Reductions 2 6, 7, 8 - Nominal Overall Ratio eg Base Mounted on Flange Diameter 2 Pole Dual speed or special motor 15, 16, 17 - Geared Motor Powers Motor Power Required M - Motorized with IEC standard motor (IE2) 12 - Motor Adaptor For Unit Types Column 10 Entries M, N, H, E, G or A R - Reducer unit S - Reducer unit with fan kit

Open the catalog to page 5

SERIES M EXPLANATION & USE OF RATINGS & SERVICE FACTORS to calculate an equivalent load to compare with catalogue ratings. Mechanical ratings and service factors Fm and Fs uniform load conditions. The unit selected must therefore have a catalogue rating at least equal to half maximum overload. our application engineers. Table 1. Mechanical Service Factor (Fm) Duration of service- Prime mover Moderate mass acceleration factor < 3 mass acceleration factor < 10 Electric motor, steam tur- Uniform mass acceleration factor < 0.2 Mass acceleration factor = all external moments of inertia * moment...

Open the catalog to page 6

SERIES M LOAD CLASSIFICATION BY APPLICATIONS Driven Machine Driven Machine Cranes main hoists U = Uniform load planer feed chains planer tilting hoist Crusher M = Moderate shock load = Refer to Application Engineering small waste Pumps centrifugal proportioning reciprocating single acting; 3 or small waste maneuvering winches pumps Machine tools rotating, swing or slew tracking, drive wheels Rubber and plastics industries Elevators Blowers centrifugal centrifugal discharge escalators freight pug mill Compressors centrifugal Conveyors-uniformly loaded or fed apron Feeders apron non-reversing...

Open the catalog to page 7

SERIES M SELECTION PROCEDURE FOR MOTORIZED UNITS 1 Mounting position Running time (%) Uniform load Electric motor, Therefore mechanical service factor (Fm) Motor Frame Size Base Mount Unit Overhung Load Service Factor Motor Frame Size Fm Base Mount Unit Overhung Load Output Speed Service Factor Output Speed Output Torque

Open the catalog to page 8

If sprocket, gear, etc is mounted on the outputshaft then refer to Overhung Loads Procedure, page 62, and compare with Fm Base Mount Unit Mass acceleration factor > 10 6 Motor Frame Size Base Mount Unit Motor Frame Size Overhung Load Motor Frame Size Base Mount Unit Overhung Load Service Factor Output Torque Overhung Load Service Factor Output Torque Output Speed Service Factor Output Torque Output Speed Output Speed SELECTION PROCEDURE FOR MOTORIZED UNITS

Open the catalog to page 9

SERIES M UNIT VERSIONS UNIT VERSIONS, COLUMN 9 ENTRY - Base Mounted Flange Mounted Flange Diameter Base and Flange Mounted Flange Diameter Flange Diameter Unit Size Triple Unit Size Triple Flange Diameter

Open the catalog to page 10

SERIES M OUTPUT SHAFT OPTIONS OUTPUTSHAFT OPTIONS L11* therefore no ‘L11’ dimension is required. OUTPUTSHAFT OPTIONS - double, triple, quadruple and quintuple reduction Inch * Standard Inch * Standard Inch * Standard Inch * Standard Inch * Standard Inch * Standard Inch * Standard Inch * Standard Inch * Standard Inch * Standard Inch * Standard

Open the catalog to page 11

SERIES M MOTOR ADAPTERS NEMA & IEC DOUBLE REDUCTION UNITS NEMA Flanges C Face - Column 12 Entry For Unit Types Column 10 Entries A, E and N Only IEC Flanges B14 - Column 12 Entry For Unit Types Column 10 Entries G, H and M Only IEC Flanges B5 - Column 12 Entry For Unit Types Column 10 Entries G, H and M Only

Open the catalog to page 12

SERIES M MOTOR ADAPTERS NEMA & IEC TRIPLE REDUCTION UNITS NEMA Flanges C Face - Column 12 Entry For Unit Types Column 10 Entries A, E and N Only IEC Flanges B14 - Column 12 Entry For Unit Types Column 10 Entries G, H and M Only IEC Flanges B5 - Column 12 Entry For Unit Types Column 10 Entries G, H and M Only

Open the catalog to page 13

SERIES M MOTOR ADAPTERS NEMA & IEC QUADRUPLE REDUCTION UNITS NEMA Flanges C Face - Column 12 Entry For Unit Types Column 10 Entries A, E and N Only IEC Flanges B14 - Column 12 Entry For Unit Types Column 10 Entries G, H and M Only IEC Flanges B5 - Column 12 Entry For Unit Types Column 10 Entries G, H and M Only

Open the catalog to page 14

SERIES M MOTOR ADAPTERS NEMA & IEC QUINTUPLE REDUCTION UNITS NEMA Flanges C Face - Column 12 Entry For Unit Types Column 10 Entries A, E and N Only IEC Flanges B14 - Column 12 Entry For Unit Types Column 10 Entries G, H and M Only IEC Flanges B5 - Column 12 Entry For Unit Types Column 10 Entries G, H and M Only

Open the catalog to page 15

TABLE 1 OIL GRADES TEMPERATURE LIMITATIONS TABLE 2 Lubrication Quantity Gallons (US)

Open the catalog to page 16

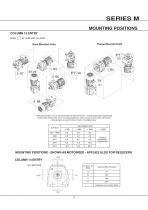

SERIES M MOUNTING POSITIONS COLUMN 13 ENTRY Flange Mounted Units Base Mounted Units Unit Size MOUNTING POSITIONS - SHOWN AS MOTORIZED - APPLIES ALSO FOR REDUCERS 270 o COLUMN 14 ENTRY Terminal Box Position

Open the catalog to page 17All BENZLERS catalogs and technical brochures

-

Series X Flexible Couplings

36 Pages

-

Roloid Gear Pump

17 Pages

-

Series P Planetary

100 Pages

-

Benzlers Screw Jacks

69 Pages

-

Series J Shaft Mounted Gearbox

73 Pages

-

Series P

4 Pages

-

Series E

4 Pages

-

Compact Motor

4 Pages

-

Series J

4 Pages

-

Series G flyer

4 Pages

-

Benzlers Product Brochure

8 Pages

-

BR Series BS

60 Pages

-

BR Cone Ring Couplings

16 Pages

-

BR Series X Couplings

36 Pages

-

BR Series H

123 Pages

-

BR Series G

71 Pages

-

BR Compact Motors

64 Pages

-

BR Series M

120 Pages

-

BR Series C

106 Pages

-

BR Series K

90 Pages

-

BR Series F

117 Pages

-

Series BD Screw Jacks

58 Pages

-

Elflex Flexible Couplings

8 Pages

-

Elign Gear Couplings

17 Pages

-

Series X

64 Pages

-

Series G

71 Pages

-

Geared Motor Series M

120 Pages

-

Geared Motor Series C

120 Pages

-

Geared Motor Series K

90 Pages

-

Geared Motor Series F

119 Pages