Catalog excerpts

rodicon** benzlers* with you at every turn with you at every turn Series BS Compact Worm Gear

Open the catalog to page 1

PRODUCTS IN THE RANGE Serving an entire spectrum of mechanical drive applications from food, energy, mining and metal; to automotive, aerospace and marine propulsion, we are here to make a positive difference to the supply of drive solutions. Series A Worm Gear units and geared motors in single & double reduction types Series BD Screwjack worm gear unit Series BS Worm gear unit Series C Right angle drive helical worm geared motors & reducers Series F Parallel angle helical bevel helical geared motors & reducers Series G Helical parallel shaft & bevel helical right angle drive gear units...

Open the catalog to page 2

Total compliance with the ATEX Directive safeguarding the use of industrial equipment in potentially explosive atmospheres is assured for users of our geared products. Certification is available for standard gearboxes and geared motors with badging displaying the CE Mark and the Ex mark, name and location of the manufacturer, designation of series or type, serial number, year of manufacture, Ex symbol and equipment group/category. ATEX directive 94/9/EC (also known as ATEX 95 or ATEX 100A) and the CE Marking Directive are enforced in all EC member states. Compliance is compulsory for...

Open the catalog to page 3

Technical information ___________________________________________________________ Selection of worm gears and worm geared motors ____________________________________ Mounting positions _____________________________________________________________ Worm Geared Motors Power ratings - Output speeds ___________________________________________________ Worm Gears Power ratings - Output speeds ___________________________________________________

Open the catalog to page 5

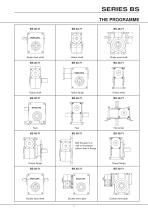

Single input shaft Hollow shaft Single input shaft Output shaft Hollow shaft Bolt the gear to a wall or foundation Double input shaft Double worm gear Double worm gear

Open the catalog to page 6

Benzlerworm gears BS 40-71 have a symmetrical gear-housing manufactured in aluminium. BS 88 and 112 have a gearhousing of cast-iron. The worm wheel is made of centrifugal cast tinbronze and the worm screw is case-hardened and ground. All motor connections are according to lEC-standard and for BS 40-112 with elastic coupling. This means • The worm screw is mounted with two separate bearings and are not connected with the motor bearings. This means longer lifetime and a smoother drive.. • Soft start and stop with elastic coupling for size • Possibility to change motor without dismounting •...

Open the catalog to page 7

Power and torque ratings for gears on page 40-47 apply to service factor 1.0. Service factor for geared motors can be found after the output speeds. Service factor 1.0 is valid for continous operation 8 hours/ day without shocks and with 10-200 starts per hour. The inertia of the driven machine is less than 20% of the electric motor. Occasional shock loads may not exceed 1.8 times the gear rating at service factor 1.0. 1. Determine the demand power or torque, Pe or T2b ratio (i) or output speed (n2). 2. Based on type of load/driven machine, operating hours/day and number of starts/hour,...

Open the catalog to page 8

Overhung load If a sprocket, gearwheel or pulley is mounted on a shaft, a load check must be made. The overhung load in middle of the shaft may not exceed values shown in tables below. For calculation of minimum permissible diameter the following formula should be Max overhung load in the middle of input shaft (N) Ff2 = Permissible overhung load (N) fb = Service factor (tables page 7) Dmin = Minimum permissible diameter (mm)

Open the catalog to page 10

Benzlers Worm gear BS, Wormwheel and Wormscrew data z = Starts of worm shaft

Open the catalog to page 11

To specify a drive precisely certain data are essential. The most important questions are listed in the table below. If you do not have the required data available in this form, we advice you to use a technical handbook or other suitable documentation. Should you have any question, please do not hesitate to contact us, Benzlers specialists will be pleased to assist you. Load designation Output power (kW): Pe at nmax at nmjn Motor Output speed (RPM): nemax nemin Operating voltage motor (V) brake (V) frequency (Hz) Output torque (Nm): Te at nmax at nmjn Overhung load (N): Fr2e at output shaft...

Open the catalog to page 12

BS (Worm gear and worm geared motor) Other combinations and sizes can be achieved. Check with Benzlers. See picture *For execution - code 2 and 3 state flange size, for example M=115, see page 55. VM = distance ring for different position of terminal box KEB = coupling/brake unit (specify type and voltage) DP = double input shaft 2 = free high speed shaft (no motor or flange for 3 = prepared for motor (specify flange and shaft diametres or I EC-standard size) FS = Fitted with forced cooling Motor sizes * = Can be changed to 0 with distance ring, VM + = Distance ring to be mounted on gear

Open the catalog to page 13

SERIES BS WORM GEARED MOTORS 0.12 kW Permissable overhung load Fr2 kN

Open the catalog to page 14

SERIES BS WORM GEARED MOTORS 0.18 kW Permissable overhung load Fr2 kN

Open the catalog to page 15

SERIES BS WORM GEARED MOTORS 0.25 kW Permissable overhung load Fr2 kN

Open the catalog to page 16

SERIES BS WORM GEARED MOTORS 0.37 kW Permissable overhung load Fr2 kN

Open the catalog to page 17

SERIES BS WORM GEARED MOTORS 0.55 kW Permissable overhung load Fr2 kN

Open the catalog to page 18

SERIES BS WORM GEARED MOTORS 0.55 kW Permissable overhung load Fr2 kN

Open the catalog to page 19

SERIES BS WORM GEARED MOTORS 0.75 kW Permissable overhung load Fr2 kN

Open the catalog to page 20

SERIES BS WORM GEARED MOTORS 1.1 kW Permissable overhung load Fr2 kN

Open the catalog to page 21

SERIES BS WORM GEARED MOTORS Output speed n2 rpm 14.76 Permissable overhung load Fr2 kN

Open the catalog to page 22

SERIES BS WORM GEARED MOTORS 3 kW Permissable overhung load Fr2 kN

Open the catalog to page 23

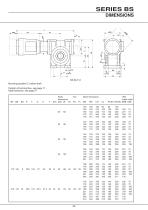

Worm geared motors BS40-112 Shaftmounted Mounting position O, hollow shaft Position of terminal box, see page 11 Shaft tolerance, see page 57 Motor- Motor dimensions Gear unit dimensions

Open the catalog to page 24

Mounting position O, hollow shaft Position of terminal box, see page 11 Shaft tolerance, see page 57

Open the catalog to page 25

Worm geared motors BS40-112 Footmounted Position of terminal box, see page 11 Shaft tolerance, see page 57 Motor- B14 B5 Gear unit dimensions size Motor dimensions

Open the catalog to page 26

Position of terminal box, see page 11 Shaft tolerance, see page 57 Shaft- Fan Motor With dimensions dimensions brake motor

Open the catalog to page 27All BENZLERS catalogs and technical brochures

-

Series X Flexible Couplings

36 Pages

-

SERIES M

94 Pages

-

Roloid Gear Pump

17 Pages

-

Series P Planetary

100 Pages

-

Benzlers Screw Jacks

69 Pages

-

Series J Shaft Mounted Gearbox

73 Pages

-

Series P

4 Pages

-

Series E

4 Pages

-

Compact Motor

4 Pages

-

Series J

4 Pages

-

Series G flyer

4 Pages

-

Benzlers Product Brochure

8 Pages

-

BR Cone Ring Couplings

16 Pages

-

BR Series X Couplings

36 Pages

-

BR Series H

123 Pages

-

BR Series G

71 Pages

-

BR Compact Motors

64 Pages

-

BR Series M

120 Pages

-

BR Series C

106 Pages

-

BR Series K

90 Pages

-

BR Series F

117 Pages

-

Series BD Screw Jacks

58 Pages

-

Elflex Flexible Couplings

8 Pages

-

Elign Gear Couplings

17 Pages

-

Series X

64 Pages

-

Series G

71 Pages

-

Geared Motor Series M

120 Pages

-

Geared Motor Series C

120 Pages

-

Geared Motor Series K

90 Pages

-

Geared Motor Series F

119 Pages