Catalog excerpts

FOR CONTINUOUS BULKING AND SHRINKAGE IHE.MA.TliX Biellci ITfllV

Open the catalog to page 1

D e s i gn e d f or continuous bulki n g an d shrin kag e ELECTRONIC CONE WINDING MACHINE mod. VA-2 Designed for continuous bulking and shrinkage of acrylic yarns, high bulk blends, elastomers and pre-dyed yarns. Exit packages can be produced with even density and accurate measured length, for use in dyeing operations or waxed for knitting purposes, or any other subsequent application. Easy to optimize the working parameters, such as the dwell time into the heating chamber or the temperature of the oven, giving a minimum Electronic yarn feeder - New version residual retraction.

Open the catalog to page 2

- Length of the inner heated chamber 450 mm Easy and quick cleaning with access from the front of the oven, can be vacuumed without removing the coiler group. - Hank circumference 1100 mm, yarn positioned onto the 4 belts by a rotating nozzle with ceramic guidance. The belt moves in increments of 1,5 mm as each coil is wound. - Programmable take-up speed from 250 to 900 mpm. - Dwell time of the yarn inside the heating chamber ranges from 20 to 60 seconds, programmable with the winding speed. - Maximum temperature of the heating chamber 160° C. - Individual stainless steel spindle chambers,...

Open the catalog to page 3

D e s i gn e d f or continuous bulki n g an d shrin kag e DESCRIPTION of the package formation Traverse 6” (152 mm) – biko type for dyeing Gas controlled arm pressure to accurately control the package density, tailstock with spring for axial compensation. Electronic yarn feeder with adjustable overfeeding from 1% to 50% to reduce and keep the yarn’s tension even at t

Open the catalog to page 4

Optical fibres yarn detection sensor at the coiler’s end - Stop / start button - Temperature warning light - Self-cleaning motorized yarn tensioner - Optical yarn detection sensor - Micrometric slub catcher (optional) - Counter rotating driven waxing device for wax disc with square hole

Open the catalog to page 5

D e s i gn e d f or continuous bulki n g an d shrin kag e DESCRIPTION OF THE CONTROL PANEL - Programmable control unit with digital display, showing production and machine operational data and self-diagnosis of eventual anomalies. Possibility to program up to 3 different working speeds and to run simultaneously 3 different lots of yarn. PROGRAMMABLE PARAMETERS FROM THE CONTROL PANEL - Take-up speed. - Anti patterning. - Yarn overfeeding, with percentage adjustment on feed and delivery. - Electronic high precision meter counter with 6 independent programs. - Feed speed increase. -...

Open the catalog to page 6

Cones conveyor belt

Open the catalog to page 7

D e s i gn e d f or continuous bulki n g an d shrin kag e DESCRIPTION OF THE AUXILIARY MOTORS Feed creel with top and tail system Trolley for the coiler removal Fume evacuation with dust filter A Overfeed motor at take-up, with setting adjustment percentage from +1% to +50% B Coiler motor B C Fan motor for the ventilation of the heating chamber

Open the catalog to page 8

The machine can be equipped with the following optional devices: Electro-Jet trolley blower, ATS Mesdan splicer installation

Open the catalog to page 9

D e s i gn e d f or continuous bulki n g an d shrin kag e Detail of the front and back view of the bulking and shrinkage winder

Open the catalog to page 10

Biella rmiv uuujuj.bemQtex-ncuj.com HEADQUARTERS 13855 VALDENGO (Biella) ITALY Via Quintino Sella, 50 Tel. +39 015 882110 r.a. PRODUCTION SITE 13885 SALUSSOLA (Biella) ITALY S.S. 143 Via Biella, 44 Tel. e fax +39 0161 993758 www.bematex-new.com www.bematex.com bematex@bematex.com

Open the catalog to page 12All BE.MA.TEX catalogs and technical brochures

-

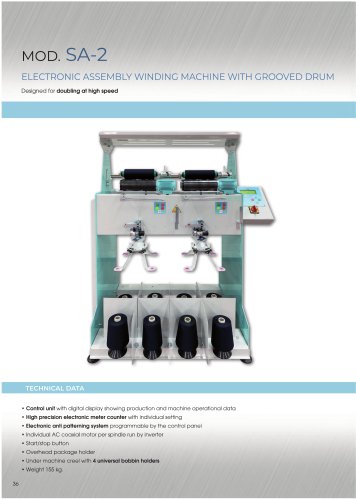

MOD SA-2

2 Pages

-

MOD CA-2 CA-4

2 Pages

-

MOD.PE

6 Pages

-

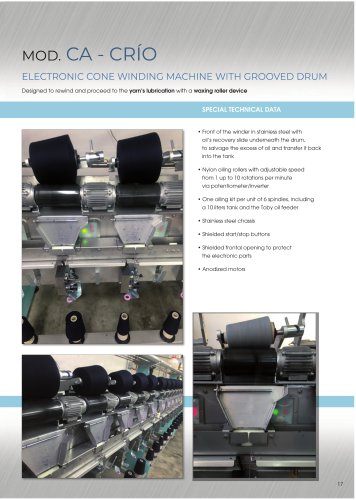

MOD CA - CRÍO

1 Pages

-

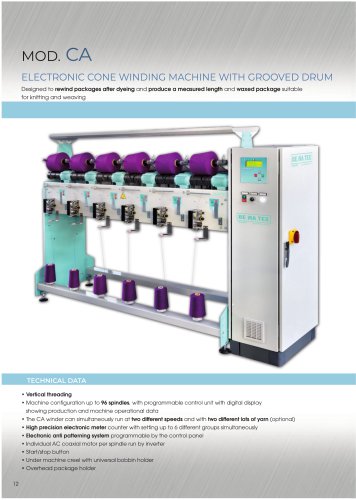

MOD CA

8 Pages

-

MOD. BU

8 Pages

-

MOD.CA-2 CA-4

2 Pages

-

MOD. PE

2 Pages

-

MOD.SA

4 Pages

-

MOD.BU

4 Pages

-

MOD.CA

4 Pages