Website:

Beltron GmbH

Website:

Beltron GmbH

Catalog excerpts

uv technology sustained • efficient and save • for a clean future Over 50 years - Quality „Made in Germa

Open the catalog to page 1

Beltron GmbH over 50 years Quality „Made in Germany“ BELTRON produces high quality machinery and equipment for many applications and markets. Generally our partners are from the graphic industry as well as from other industrial applications. Besides the printing and reproduction market and the electronic industry, the bran “BELTRON” has been approved in many other fields, such as solar industry, nano technology, uv-hardening of glue, medical industry, glass industry, automobile industry, production of furniture or other wood based applications, manufacturing of concrete plates, are just a...

Open the catalog to page 2

Application: For drying and polymerization of uUV screen inks, UV adresives, for printed circuit boards, laminated materials, plastic, paper, glass, metal and other printed materials in flow process. Machines of BE type can be delivered with working width of 35 to 260 cm and lamp power of 80 to 120 W/cm and can be equipped with 1 to 3 bulps. Design: Compact, space saving steel construction, belt speed 0,5 – 12 m/min stepless controllable (other ranges possible), electronical lamp cooling system, easy and fast lamp exchange, alu lamp casing with uv bulp with 120 W/cm caspacity, stepless...

Open the catalog to page 3

Application: Uv curing and uv post-polymerisation of photoimageable soldermask on printed circuit boards and flex-boards. Ausführung: The developed soldermask will be final UV cured in addition to the final thermal curing process. The post- polymerisation process improves the surface characteristics of the solder mask regarding resistance to chemicals in the nickel gold bath, during hot air leveling, in chemical or galvanic tin bath along with the electric surface properties. Exposure time can be reduced to a minimum because the final properties are realized by UV polymerisation. Technical...

Open the catalog to page 4

Applictaion: The Slimsize UV dryer is ideal for use in existing systems and is suitable for products such as paper, cardboard, foil, glass, circuit boards, plastics, wood and metal. Due to its overall width of only 600 mm it can be integrated in any system concept (also later on). The UV-dryer is available with one UV lamp or as double-sided UV dryer with one UV lamp above and 1 below the product. Design: Steel structure in Slimsize version, belt speed in the range 1:10 infinitely adjustable, electronically controlled cooling system, radiator power continuously variable 30-100%, simple and...

Open the catalog to page 5

Application: For uv curing of conformal coatings and solvent-free thick film lacquers on pcbs or other 3D objects such as: uv thick film lacquers TWIN CURE ® from Peters Lackwerke or Dymax Corp. and other uv products. Design: PFT-conveyor belt with suction/cooling system, max. working width 350 mm, max. working height adjustable between 25 and 95 mm, belt speed adjustable in the range of 1:10, i.e. 2-20 m/min, belt speed 0,5 – 12 m/min stepless controllable (other ranges possible), stepless power control in the range of 30 - 100% for optimal UV radiation,easy and fast replacement of UV...

Open the catalog to page 6

edge conveyor Application: UV drying and curing of all UV reactive materials, i.e. conformal coatings, adhesives, resins and UV inks. Useable for stand alone and inline production. Design: The continuously adjustable power control of the lamps between 40 and 100 % UV output enables an optimal adjustment of the UV power ( 500–5000 mJ/cm² ) to the belt speed ( 0,3 to 3,0 m/min ). Advantages: UV-cross linking during fast horizontal transport, controlled UV dose on substrates, flexible adaptation to different process requirements, program storage in the PLC control. Technical Information UV...

Open the catalog to page 7

Application: For drying and polymerization of inks, coatings and adhesives for printed circuit boards, laminated materials, plastic, paper, glass, metal and other printed materials in flow process. The lamp power lasts from 80 to 120 W/cm and the machines are equipped with 1 or 2 UV lamps. This UV dryers are used for laboratory operation or small size production. Design: Teflon belt (PTFE-coated), with maintenance-free adjustable belt drive 0,5—12 m/min (optional other range), belt width 220 mm with 1 or 2 UV lamp units, with special aluminum reflectors or (upon request) with selective...

Open the catalog to page 8

UV-IR dryer Application: For drying and polymerization of uv screen inks, uv adhesives for printed circuit boards, laminated materials, plastic, paper, glass, metal and other printed materials in flow process. The lamp power lasts from 80 to 120 W/cm and the machines are equipped with 1 to 3 uv lamps. As well as up to 3 IR modules. This UV-IR dryers are used for laboratory operation or small size production. Design: Teflon belt (PTFE-coated) or stainless steel belt, belt width 200 mm with uv lamps , with special aluminum reflectors mit or (upon request) with selective filters for...

Open the catalog to page 9

UV minidryer Application: For drying and polymerization of UV screen inks, UV adhesives for printed circuit boards, laminated materials, plastic, paper, glass, metal and other printed materials in flow process. Design: Unit ready for operation with one uv lamp unit. The electric control is located in the transportation device, designed for uninterrupted operation in drying of small sized materials. The uv bulb is located in an air-cooled casing with aluminum reflector, with counter for operation hours, power switch, lamp ON/OFF, 100%/50% lamp power and stepless speed control (approx. 2 - 27...

Open the catalog to page 10

UV chamber Application: Applications of the UV-chamber are numerous. Besides the standard tasks such as curing and glueing, the chamber may be used for material testing and radiation for chemical and biolegical applications. Design: UV-chamber for laboratory and manual production, various UV emission spectra are possible due to combination of UV lamps and UV filter, manual lamp shutter or optional as automatic electric shutter with timer, high safety by interlocking the door during UV exposure resp. the shutter can not be opened while the door is open, equipped with operating hours counter...

Open the catalog to page 11All Beltron GmbH catalogs and technical brochures

-

Electronic Ballast EVG

2 Pages

-

Transformers + Ballast

2 Pages

-

Cold Light Selective Filters

2 Pages

-

UV hand lamp

1 Pages

-

Beltromat 8100

2 Pages

-

LED-UV Integrator

2 Pages

-

Beltrocop S

2 Pages

-

Beltroframe S

1 Pages

-

UV minibridge

1 Pages

-

Beltron catalog

79 Pages

-

UV-Meter

1 Pages

-

UV-Integrator Typ D

1 Pages

-

Fitted lamps BELTROLUX W

1 Pages

-

Mini copy frame S

1 Pages

-

Beltroquick S

1 Pages

-

Mobile UV bridge

1 Pages

-

LED – UV Chain Conveyor

1 Pages

-

UV dryer Slimsize

1 Pages

-

One-Sided continous-dryers

1 Pages

-

UV dryer

18 Pages

-

UV Compact Modules

1 Pages

-

UV Mini Bridge

1 Pages

-

LED UV dryer BE 7

1 Pages

-

LED UV dryer BE 15

1 Pages

-

LED UV dryer BE 20

1 Pages

-

UV Minidryer

1 Pages

-

UV-IR Laboratory dryer BE 20

1 Pages

-

UV Laboratory dryer BE 20

1 Pages

-

UV-Integrator Typ I

1 Pages

-

IR-Module Ermitters

1 Pages

-

Fitted lamps - BELTROLUX W

1 Pages

-

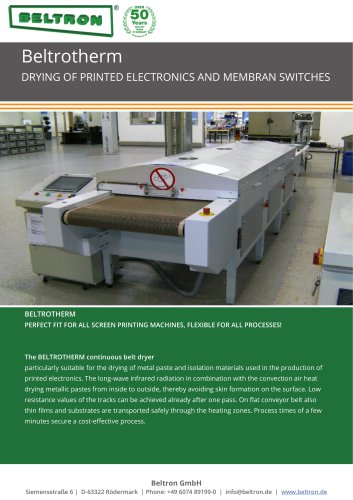

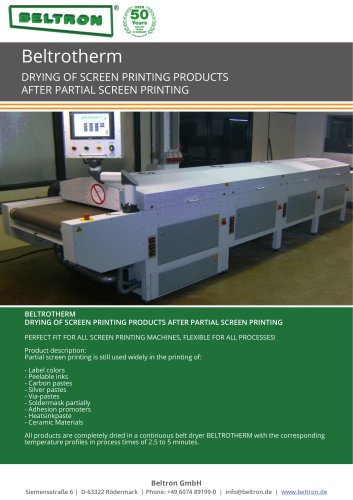

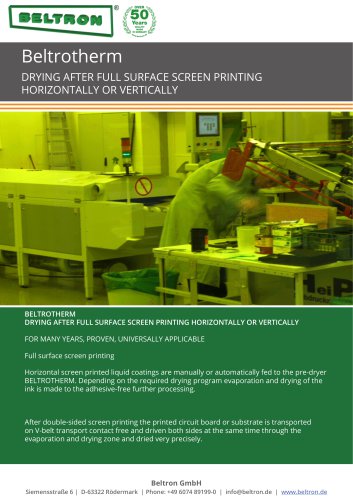

Thermo-Dryer BELTROTHERM

4 Pages

-

UV Chamber

1 Pages

-

UV dryer with Edge Conveyor

1 Pages