Website:

Beltron GmbH

Website:

Beltron GmbH

Catalog excerpts

Spot cures The Process Control You Need Without the Added Cost! The Beltron UV-Spot 200 UV curing spot lamp offers the highest intensity and most user-friendly operation in the industry. The new intensity adjustment feature allows users to manually adjust intensity. The patent pen- ding intensity adjustment feature assists users in validating an appropriate intensity range and maintaining that range during production. Intensity measurement Is easily accomplished with the ACCU-CAL 50 radiometer. Scheduled intensity measurements taken during the production process will indicate whether additional intensity adjustments are required. This method of measurement provides the most accurate readings as they are taken through the lightguide In the actual production setting. The Beltron UV-Spot 200 spot lamp primarily emits UVA and blue visible light (300-450 nm) and Is designed for UV curing of adhesives, coatings and encapsulants. It contains an integral shutter which can be actuated by a foot pedal or PLC making it ideal for both manual and automated processes. A universal power Input provides consistent performance at any voltage (90-264V, 47-63 Hz). Beltron also offers a wide range of long-lasting lightguides including liquid/fiber, single/multi-pole and lightguides In various lengths. The Beltron UV-Spot 200 with manual intensity adjustment is the most versatile, user-friendly and reliable UV curing spot lamp available. How Does the Beltron UV-Spot 200 New Intensity Adjustment Feature Work? All bulbs used to power high intensity UV curing spot lamps degrade over time from normal use. This typically results in a gradual decrease In total intensity as the bulb ages (shown in Chart 1), Recognizing this, UV curing processes are usually validated using the lowest acceptable intensity level to maximize bulb life. However, this means that for the majority of the production process, curing is being done with a higher intensity level than is actually necessary, and it can be expected that the intensity will be decreasing over time. With the Beltron UV-Spot 20Q's new intensity adjustment feature, users can maintain the qualified intensity range by manually increasing intensity output to offset this degradation. The adjustment is easily accomplished with the provided adjusting tool or using the removable knob as shown in the photographs below. This feature is useful for both process validation and subsequent process control during production. Prior to production, BELTRON advises customers to conduct testing to determine the exposure time and intensi- ty required to achieve full cure. Validating a UV curing process can be accomplished in one of two ways: Set Exposure Time, Determine Intensity Users can specify a cure time and through empirical testing, determine the intensity required to achieve full cure. Set Intensity, Determine Exposure Time Users can specify intensity (perhaps one that maximizes bulb life) using Table 1. through empirical testing to determine the exposure time required to Note: As with any manufacturing process, it Is advisable to Incorporate a safety factor. UV process validation identifies a minimum acceptable intensity range that ensures complete cure in an accep- table cycle time. Users can choose to operate at full intensity (intensity adjusted to 100%) or maintain a cons- tant intensity (at some lower level) through periodic manual adjustments. The average Beltron UV-Spot 200 bulb will typically degrade < 1% per eight hours of normal use. The good manufacturing practice of routine intensity measurement with a calibrated radiometer will determine when and if any adjustments are required.

Open the catalog to page 1All Beltron GmbH catalogs and technical brochures

-

Electronic Ballast EVG

2 Pages

-

Transformers + Ballast

2 Pages

-

Cold Light Selective Filters

2 Pages

-

UV hand lamp

1 Pages

-

Beltromat 8100

2 Pages

-

LED-UV Integrator

2 Pages

-

Beltrocop S

2 Pages

-

Beltroframe S

1 Pages

-

UV minibridge

1 Pages

-

uv technology

14 Pages

-

Beltron catalog

79 Pages

-

UV-Meter

1 Pages

-

UV-Integrator Typ D

1 Pages

-

Fitted lamps BELTROLUX W

1 Pages

-

Mini copy frame S

1 Pages

-

Beltroquick S

1 Pages

-

Mobile UV bridge

1 Pages

-

LED – UV Chain Conveyor

1 Pages

-

UV dryer Slimsize

1 Pages

-

One-Sided continous-dryers

1 Pages

-

UV dryer

18 Pages

-

UV Compact Modules

1 Pages

-

UV Mini Bridge

1 Pages

-

LED UV dryer BE 7

1 Pages

-

LED UV dryer BE 15

1 Pages

-

LED UV dryer BE 20

1 Pages

-

UV Minidryer

1 Pages

-

UV-IR Laboratory dryer BE 20

1 Pages

-

UV Laboratory dryer BE 20

1 Pages

-

UV-Integrator Typ I

1 Pages

-

IR-Module Ermitters

1 Pages

-

Fitted lamps - BELTROLUX W

1 Pages

-

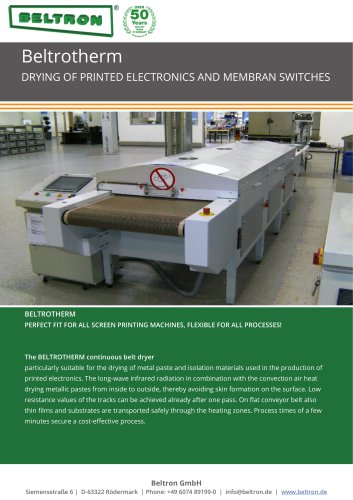

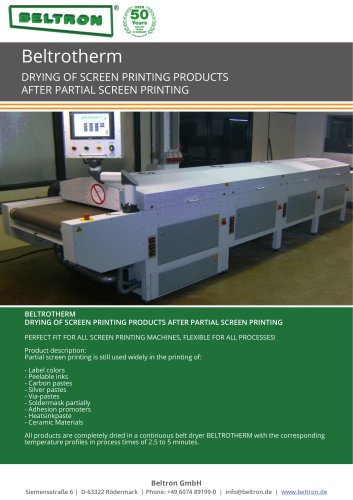

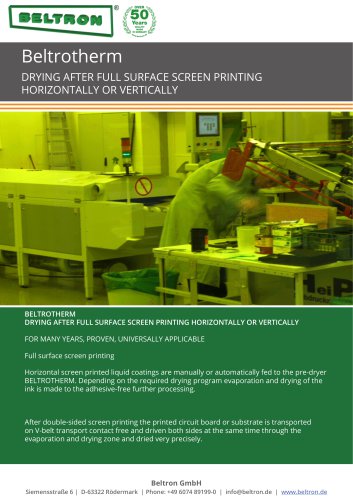

Thermo-Dryer BELTROTHERM

4 Pages

-

UV Chamber

1 Pages

-

UV dryer with Edge Conveyor

1 Pages