Website:

Beltron GmbH

Website:

Beltron GmbH

Catalog excerpts

Double-Sided continous-dryers Application: Uv curing and uv post-polymerisation of photoimageable soldermask on printed circuit boards and flex-boards. Advantages: The developed soldermask will be final uv cured in addition to the final thermal curing process. The postpolymerisation process improves the surface characteristics of the solder mask regarding resitance to chemicals in the nickel gold bath, during hot air levelling, in chemical or galvanic tin bath along with the electric surface properties. Exposure time can be reduced to a minimum because the final properties are realized by uv polymerisation. Technical Data: 2 Medium pressure uv lamps, 800 mm active length 1 uv lamp below and 1 uv lamp above the conveyer system Uv energy 2000 mJ/cm² +/- 5 % at 1,7 m/min conveyor speed Conveyor speed: Conveyor speed 1,0 to 6,0 m/min adjustable Dimensions of PCB: Width: 100 up to 720 mm Length: 100 up to 760 mm Thickness: 0,4 up to 5,0 mm Panel warpage: max. +/- 6mm Dimension of the machine: Lenght: 1500 mm Height: 1160 mm Width: 1300 mm Air cooling approx. 30 m³/min. Electrical supply: 400 V / 50 Hz / 3~, 20 kW, 3 x 50 A CE-Sign Beltron GmbH 63322 Rödermark Telefon: 06074-89199-0 Telefax: 06074-89199-29 Email: info@beltron.de Internet: www.beltron.de

Open the catalog to page 1All Beltron GmbH catalogs and technical brochures

-

Electronic Ballast EVG

2 Pages

-

Transformers + Ballast

2 Pages

-

Cold Light Selective Filters

2 Pages

-

UV hand lamp

1 Pages

-

Beltromat 8100

2 Pages

-

LED-UV Integrator

2 Pages

-

Beltrocop S

2 Pages

-

Beltroframe S

1 Pages

-

UV minibridge

1 Pages

-

uv technology

14 Pages

-

Beltron catalog

79 Pages

-

UV-Meter

1 Pages

-

UV-Integrator Typ D

1 Pages

-

Fitted lamps BELTROLUX W

1 Pages

-

Mini copy frame S

1 Pages

-

Beltroquick S

1 Pages

-

Mobile UV bridge

1 Pages

-

LED – UV Chain Conveyor

1 Pages

-

UV dryer Slimsize

1 Pages

-

One-Sided continous-dryers

1 Pages

-

UV dryer

18 Pages

-

UV Compact Modules

1 Pages

-

UV Mini Bridge

1 Pages

-

LED UV dryer BE 7

1 Pages

-

LED UV dryer BE 15

1 Pages

-

LED UV dryer BE 20

1 Pages

-

UV Minidryer

1 Pages

-

UV-IR Laboratory dryer BE 20

1 Pages

-

UV Laboratory dryer BE 20

1 Pages

-

UV-Integrator Typ I

1 Pages

-

IR-Module Ermitters

1 Pages

-

Fitted lamps - BELTROLUX W

1 Pages

-

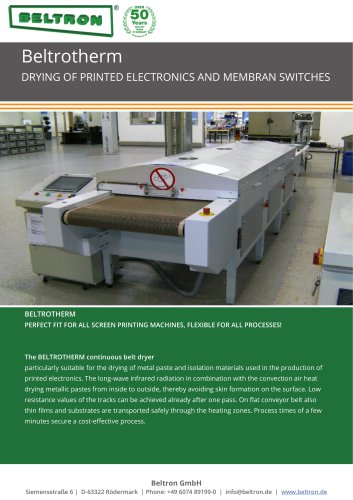

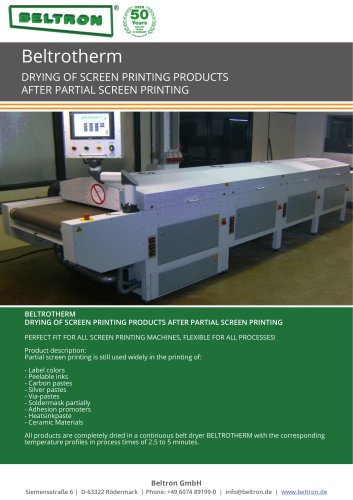

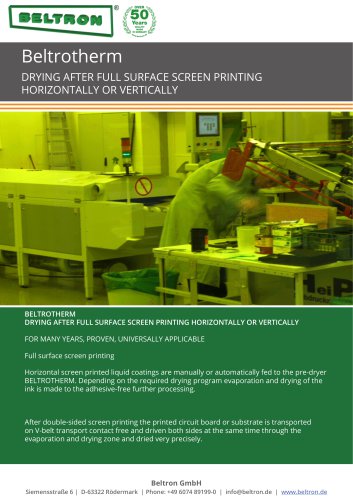

Thermo-Dryer BELTROTHERM

4 Pages

-

UV Chamber

1 Pages

-

UV dryer with Edge Conveyor

1 Pages