Catalog excerpts

STANDARD EQUIPMENT ENGINE ■ Engine, HINO J08E, Diesel engine with turbocharger and intercooler ■ Automatic engine deceleration Auto Idle Stop (AIS) ■ Batteries (2 x 12V - 96Ah) ■ Starting motor (24V - 5 kW), 50 amp alternator ■ Removable clean-out screen for radiator ■ Automatic engine shut-down for low engine oil pressure ■ Engine oil pan drain valve ■ Double element air cleaner CONTROL ■ Working mode selector (H-mode and S-mode) ■ Power Boost SWING SYSTEM & TRAVEL SYSTEM ■ Swing rebound prevention system ■ Straight propel system ■ Two-speed travel with automatic shift down ■ Sealed & lubricated track links ■ Grease-type track adjusters ■ Automatic swing brake HYDRAULIC ■ Arm regeneration system ■ Auto warm up system ■ Aluminum hydraulic oil cooler MIRRORS & LIGHTS ■ Two rearview mirrors ■ Two front working lights Wide range of buckets Various optional arms Wide range of shoes Additional track guide CAB & CONTROL ■ Two control levers, pilot-operated ■ Tow eyes ■ Horn, electric ■ Integrated left-right slide-type control box ■ Cab, all-weather sound suppressed type ■ Cab light (interior) ■ Luggage tray ■ Large cup holder ■ Detachable two-piece floor mat ■ 7-way adjustable suspension seat ■ Retractable seatbelt ■ Headrest ■ Handrails ■ Heater and defroster ■ Intermittent windshield wiper with double-spray washer Skylight ■ Tinted safety glass ■ Pull-type front window and removable lower front window ■ Easy-to-read multi-display monitor ■ Automatic air conditioner ■ Emergency escape hammer ■ Travel alarm Additional hydraulic circuit Arm rest Additional counterweight Multi-control valve Note: This catalog may contain attachments and optional equipment that are not available in your area. And it may contain photographs of machines with specifications that differ from those of machines sold in your areas. Please consult your nearest KOBELCO distributor for those items you require. Due to our policy of continuous product improvements all designs and specifications are subject to change without advance notice. Copyright by K0BELC0 C0NST00CTI0N MACHINERY CO., LTD. r without notice. WeQaveYouFuel Achieving a Low-Carbon Society

Open the catalog to page 1

The SK Series Concept of Beautiful Performance. The Power Wave of Change When we set out to design our new hydraulic excavators, we kept our eyes on the big picture. Of course we wanted machines with greater diggin capacity. But they also had to be fuel-efficient andeconomical, while imposing less of a burden on the local and global environments. Applying our advanced technologies, we developed SK series, an entirely new kind of excavator that beautifully balances all the demands of today’s construction industry. Lean and efficient with capacity to spare, these sleek powerhouses bring a...

Open the catalog to page 2

Efficient Performance! NEXT-3E Technology Next-Generation Electronic Engine Control The high-pressure, common-rail fuel-injection engine features adjustable control to maximize fuel efficiency and provide powerful medium/low-speed torque. The result is a highly fuel-efficient engine. Amazing Productivity with a 27 % Increase in Work Volume and “Top-Class” Cost-Performance Work Volume * For heavy duty when a higher H-Mode performance level is required. increase in work volume using the same amount of fuel. (H-Mode) Fuel Consumption* decrease in fuel consumption even when performing more work...

Open the catalog to page 3

Reliability, Durability, Environmental Responsibility The Value and Quality of Sturdy Construction! Designed for the Environment and the Future! Emergency Acceleration (Dial) Permits Continued Operation in the Unlikely Event of Malfunction Stable Attachment Strength If unexpected trouble is experienced with the ITCS mechatronic control system, the machine can still be operated using the emergency acceleration system. Digging modes are also automatically relayed to an emergency system so that digging can continue temporarily until a service person arrives to repair the primary system. Forged...

Open the catalog to page 4

left side cover Highly Durable Super-fine Filter The high-capacity hydraulic oil filter incorporates glass fiber with superior cleaning power and durability. With a replacement cycle of 1,000 hours and a construction that allows replacement of the filter element only, it’s both highly effective and highly economical. Parallel Cooling Units Are Easy to Clean Comfortable "On the Ground" Maintenance The machine layout was designed with easy inspection and maintenance in mind. Super-fine filter Double-Element Air Cleaner as Standard Oil cooler right side cover A new fuel filter has been...

Open the catalog to page 5

Designed from the Operator’s Point of View Newly Designed Information Display Prioritizes Visual Recognition The analog gauge provides information that’s easy to read regardless of the operating environment. The information display screen has been enlarged, and a visor is attached to further enhance visibility. Imagining Possible Scenarios and Preparing in Advance Bracket for Attaching a Head Guard Provided as Standard Equipment A bracket is provided as standard equipment that allows the optional head guard to be simply bolted on. Wide Field of View Liberates the Operator The front field of...

Open the catalog to page 6

Working Ranges •Previous indication Travel motors: Hydraulic System Swing System Swing motor: All-weather, sound-suppressed steel cab mounted on the silicon-sealed viscous mounts and equipped with a heavy, insulated floor mat. Operating Weight & Ground Pressure

Open the catalog to page 7

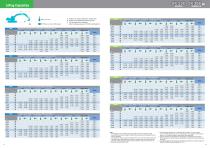

Rating over front A- Rating over side or 360 degrees A - Reach from swing centerline to bucket hook B - Bucket hook height above/below ground C - Lifting capacities in kilograms • Max. discharge pressure: 37.8 MPa (385 kgf/cm2) Standard Arm: 3.3 m Bucket: 1.4 m3 ISO heaped 1,070 kg Shoe: 600 mm 4. The above lifting capacities are in compliance with ISO 10567. They do not exceed 87% of hydraulic lifting capacity or 75% of tipping load. Lifting capacities marked with an asterisk (*) are limited by hydraulic capacity rather than tipping load. 5. Operator should be fully acquainted with the...

Open the catalog to page 8All Bell Equipment Co SA catalogs and technical brochures

-

5th Wheel Conversion

2 Pages

-

B25D

2 Pages

-

ADT

2 Pages

-

B25D Hooklift Truck

2 Pages

-

220E

2 Pages

-

924J

4 Pages

-

914J

4 Pages

-

Versa Truck

3 Pages

-

E-series Water Tankers

16 Pages

-

G series

20 Pages

-

SK850LC

8 Pages

-

Hydraulic Excavators SK500HD

8 Pages

-

Hydraulic Excavators SK380HD

8 Pages

-

Hydraulic Excavators

8 Pages

-

ACERA GEOSPEC SK125SR/SK135SR-2

16 Pages

-

SK75R

9 Pages

-

Mini excavator sk55SRX

6 Pages

-

E-series 4*4

12 Pages

-

Rigid Hauler Tractors

11 Pages

-

11 Cube Dumper Trailer

2 Pages

-

Loaders Wheeled loader

28 Pages

-

B33L LOW PROFILE 4X4

4 Pages

-

B30L LOW PROFILE 4X4

4 Pages

-

Dozer 850J

4 Pages

-

315SL

12 Pages

-

B33L

4 Pages

-

2306D 5th Wheel Conversions

2 Pages

-

bell tractor

11 Pages

-

125A Tri-wheeler

4 Pages

-

9 Cube Dumper

2 Pages

-

315SK

8 Pages

-

120A Forklift

12 Pages

-

C-1550 Cone Crusher

8 Pages

-

G-Series Motor Grader

20 Pages

-

I-130RS Impact Crusher

12 Pages

-

J-750 Jaw Crusher

12 Pages

-

225A Crank Boom

4 Pages

-

TH302 Hauler

3 Pages

-

L1004E Wheeled Loader

4 Pages

Archived catalogs

-

E-series

28 Pages

-

E-Series_2013

28 Pages

-

L705E Wheeled Loader

4 Pages

-

1226A & 1226AF Rigid Tractor

4 Pages

-

Product Range

48 Pages

-

Backhoe Loader

4 Pages

-

Single Drum Compactor

4 Pages

-

Motor Grader 670D

6 Pages

-

Bulldozer 850J

4 Pages

-

Articulated Dump Truck B50D

6 Pages

-

Crawler Excavator B215CDLC

9 Pages

-

Crawer Excavator HD2045

8 Pages

-

Wheel Loader

48 Pages