Website:

Bekum Maschinen Fabriken

Website:

Bekum Maschinen Fabriken

Catalog excerpts

Packaging Machines High Performance Blow Moulding Machines FOOD & BEVERAGE CONSUMER PACKAGING

Open the catalog to page 1

ELECTRIC AND HYDRAULIC BLOW MOULDING MATERIAL SAVING AND ENERGY EFFICIENT PACKAGING PRODUCTION Production of up to 2 × 14 articles per cycle with a blow mould width of 1,060 mm are possible on a double-station blow moulding machine of type EBLOW 807D. Our packaging machines for consumer, food & beverage, and pharmaceutical packaging are optionally available as electric or hydraulic single and double station machines for economic, round-the-clock production. Centrepieces of our packaging machines are the clamping unit feature a C-frame, which was developed and patented by our specialists,...

Open the catalog to page 2

Crystal-clear handle containers made of PET are produced reliably and exclusively on Bekum blow moulding machines. Innovative Clamping Unit To meet your production philosophy, we offer either the energy-saving electric or the classic hydraulic blow moulding machines. Both types are based on the same, unique clamping concept – the patented C-frame. The design of the C-frame, which utilizes mould platens that move along precise, low-friction linear guides, enables completely symmetrical clamp force distribution along the entire mould area, while maintaining high parallelism of the mould...

Open the catalog to page 3

FEATURES THAT MAKE THE DIFFERENCE. MORE PACKAGING. MORE FLEXIBILITY. MORE CONTROL. High Output Bekum‘s high-output technologies, “Multi-Cavity”, “Tandem Blow” and “Highspeed” guarantee high output rates and a high overall system efficiency for packaging, bottles and containers of different sizes. When it comes to the Multi-Cavity concept, everything revolves around the maximum number of articles to be produced by each blow mould on our packaging machines. Smaller packaging units can also be manufacturer reliably and in very high volumes of up to 18,000 pcs./hour using the Tandem Blow method...

Open the catalog to page 4

Bekum Control 8.0 ew machine control Bekum Control 8.0 ease the opeN ration of the machine ntuitive user interface I ndustry 4.0 ready I lear and up-to-date information overview in a custoC mizable dashboard isualization of throughput values and energy consumpV tion isplay of electricity, water and air consumption as well D as the pressures of all supplied media enerously dimensioned portrait-oriented 24 „full-HD G touch-screen control unit eduction of switching elements on the control panel R n connection with new control - optional hand operai ting device for quick setup Magnetic Quick...

Open the catalog to page 5

EXTRUSION SYSTEM ACCORDING TO YOUR NEEDS FROM A SINGLE SOURCE. MATCHED. REPRODUCIBLE PRODUCT QUALITY. Bekum is one of the technology leaders in extrusion blow moulding. For this reason, it is important to us to have the core competencies of extrusion for mono, bi-ex and co-extrusion heads and extruders in-house. We develop, design, manufacture and assemble the core components independently. Thus, as with the blow moulding machine, we have a direct influence on the rheological design and manufac- 1. Outer Layer - Virgin and Color 2. Middle Layer - PCR and Regrind 3. Inner Layer - Virgin 1....

Open the catalog to page 6

HiPEx - High Performance Extruder The name HiPEx 36 conceals a completely redeveloped more powerful extruder generation. The main focus lay in the efficiency of the system as a whole. The new HiPEx generation of extruders for the future packaging machine series are characterised by their exceptional process stability, their high maximum throughput capacities and their excellent melt homogeneity. When designing extruders, Bekum places particular emphasis on a high degree of energy efficiency, as extruders are the main energy consumer of blow moulding machines. Thanks to the installation of...

Open the catalog to page 7

Technical Specification Single-‐ and Twin-‐Station Mould length, max. incl. 50 mm overhang (mm) Article Production Possibilities, max. (L) Rights reserved to alterations. Center distance Cavities Bekum Maschinenfabriken GmbH Kitzingstraße 15/19 12277 Berlin

Open the catalog to page 8All Bekum Maschinen Fabriken catalogs and technical brochures

-

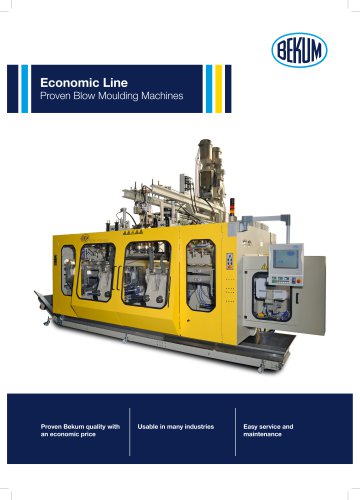

Economic Line

2 Pages

-

Multi-Cavity

2 Pages

-

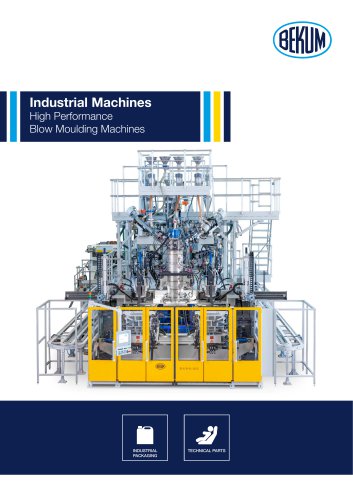

Industrial Machines

8 Pages

-

Co-Extrusion

12 Pages

-

Company Brochure

16 Pages