Catalog excerpts

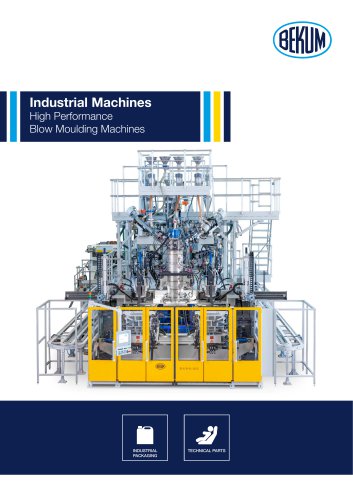

Industrial Machines High Performance Blow Moulding Machines INDUSTRIAL PACKAGING TECHNICAL PARTS

Open the catalog to page 1

HIGH-SPEED PRODUCTION OF INDUSTRIAL BLOW MOULDED PRODUCTS COMPACT MACHINES FOR FLEXIBLE CONFIGURATION The Industrial Machines of Bekum are considered the most reliable industrial packaging machines available worldwide. They form the benchmark with their output capacity and production flexibility for canisters, small drums, liners and water containers. With an energy-efficient drive technology, Bekum offers its customers the optimum conditions for high-performance production of industrial blow moulded products. In particular, these machines are distinguished by diverse and reliable...

Open the catalog to page 2

20 L canister produced with chalk (Tri-Extrusion) BA 34.2D Tri-Extrusion of canister with view strip The advantages of the electric EBLOW 37 at a glance: Features of both drive concepts for EBLOW 37 & BA 34.2/D: High energy efficiency Increased Productivity to 50 % energy savings on the blowing machine Up compared to conventional hydraulic systems to 15 % increase in output, which yields production Up of up to 240 canisters per hour 20 litre lightweight energy required to maintain the clamping pressure No Variable setting of clamping movement and speed on the operating panel Unique...

Open the catalog to page 3

FLEXIBLE BLOW MOULDERS FOR TWO OPERATIONS FOR HOLLOW BODIES UP TO 120 L AND TECHNICAL PARTS The BA 62S large blow moulding system is a veritable all-rounder for most popular applications range from 60 litre canisters to 120 litre wide-neck drums, special parts for air conveyance and spoilers for the automobile industry, as well as a diverse range of technical parts. It is available in a range of designs such as single and double-station and shuttle-machines with mobile clamping units and offers equipment to enable the optimal changing of moulds and dies. The combination of tie rods (bars)...

Open the catalog to page 4

Bottom calibration with parison spreading device Other features Excellent flexibility Continuous and discontinuous (accumulator head) extrusion Article take-out can be done to the left or right, both across and along the extruder axis Production options with view stripe Coupled tiebars for long parts and engineering plastics with low material viscosity Monolayer, tri-and co-extrusion with regrind material and chalk processing Generous clamping plates for a double production Interface for process robots for insertion and removal Good accessibility for process setting and...

Open the catalog to page 5

EXTRUSION SYSTEM ACCORDING TO YOUR NEEDS FROM A SINGLE SOURCE. MATCHED. REPRODUCIBLE PRODUCT QUALITY. Bekum is one of the technology leaders in extrusion blow moulding. For this reason, it is important to us to have the core competencies of extrusion for mono, bi-ex and co-extrusion heads and extruders in-house. We develop, design, manufacture and assemble the core components independently. Thus, as with the blow moulding machine, we have a direct influence on the rheological design and manufac- 1. Outer Layer - Virgin and Color 2. Middle Layer - PCR and Regrind 3. Inner Layer - Virgin 1....

Open the catalog to page 6

HiPEx - High Performance Extruder The name HiPEx 36 conceals a completely redeveloped more powerful extruder generation. The main focus lay in the efficiency of the system as a whole. The new HiPEx generation of extruders for the future packaging machine series are characterised by their exceptional process stability, their high maximum throughput capacities and their excellent melt homogeneity. When designing extruders, Bekum places particular emphasis on a high degree of energy efficiency, as extruders are the main energy consumer of blow moulding machines. Thanks to the installation of...

Open the catalog to page 7

Technical Specification Single-‐ and Twin-‐Station Article Production Possibilities, max. (L) Technical Parts Bekum Maschinenfabriken GmbH Kitzingstraße 15/19 12277 Berlin sales@bekum.com www.bekum.com

Open the catalog to page 8All Bekum Maschinen Fabriken catalogs and technical brochures

-

Packaging Machines

8 Pages

-

Economic Line

2 Pages

-

Multi-Cavity

2 Pages

-

Co-Extrusion

12 Pages

-

Company Brochure

16 Pages