Catalog excerpts

OUR TECHNOLOGY YOUR SUCCESS FOOD & BEVERAGE CONSUMER PACKAGING INDUSTRIAL PACKAGING TECHNICAL PARTS SOLUTIONS FOR YOUR APPLICATIONS

Open the catalog to page 1

WELCOME TO BEKUM No other company in the world has characterised the developments on the market for blow moulders over the past few decades as much as Bekum. Our family run Company, formed in 1959, is the most experienced company in our industry. We have been able to do well for so long, and have grown to become one of the global market leaders due to our unique product range, our innovative, top-quality machine solutions, and first-rate global service. We are always one step ahead of the rest as evidenced by our introduction of the first “neck calibration” in the year Bekum was formed....

Open the catalog to page 2

Mission & Managment Customer satisfaction is the basis of our business success. Our customers expect and receive quick feedback on their blow moulding challenges. Their requirements motivate us to continuously develop tailor-made machine and service solutions for all their blow moulding needs. The Bekum promise of quality, technology and service provides our customers a decisive competitive advantage in the marketplace. This unique selling point makes Bekum the Industry’s benchmark for blow moulding machinery. Our focus is quality. As a true pioneer in the industry, the Bekum name stands...

Open the catalog to page 3

2019 150 years experience: 60 years Berlin, 50 years Traismauer, 40 years Williamston 2019 Presentation of the new machine generation Concept 808 2019 Plant expansion Bekum America 2018 Plastics Hall of Fame induction of Martin Stark – Chairman Bekum America 2018 First magnetic quick change system for blow moulding machines 2016 New headquarters in Berlin 2015 Production locations focused in Traismauer/Austria 2014 Foundation of Bekum Asia in China 2007 Introduction of the first fully electric blow moulding machine 2010 Patent for the C-frame closing unit for electrical and hydraulic blow...

Open the catalog to page 4

THREE LOCATIONS ONE GOAL BERLIN / GERMANY Since 1959, Berlin is the world headquarters of Bekum and remains the guiding business center of the company today. In our new building complex, development and design of automatic high-performance packaging machines under 20 L in capacity occurs, as well as extruders and extrusion heads. Also located in Berlin are our worldwide sales and service units. TRAISMAUER / AUSTRIA At the Traismauer site, since 1968, in addition to in-house mechanical engineering, we have been developing, constructing, manufacturing, distributing and servicing Bekum...

Open the catalog to page 5

Food & Beverage OPTIMISED FUNCTIONS MINIMUM UNIT COSTS FOOD & BEVERAGE The market for small format drinking bottles of between 50 and 1,500 ml has been enjoying above-average sales growth for several years, including milk-based drinks, fruit juice and functional drinks. In order to do justice to this trend, we have developed high-output solutions and “Tandem Blow” technology, which allows low-cost production at premium quality for extremely large quantities. In addition, we have decades of experience in “sterile blow” moulding for plastic packaging, which meets strict statutory requirements...

Open the catalog to page 6

Food & Beverage THE ADVANTAGES OF OUR HIGHPERFORMANCE BLOW MOULDING MACHINES: PRODUCTION EXAMPLES: Patented C-frame clamping unit guarantees optimised clamping force distribution and high mould platen parallelism agnetic Quick change M for mould and pin Reduced material consumption while optimising the layer thickness distribution and use of recycled material Reproducible article quality Next-generation intuitive control technology Bekum Control 8.0 with Industry 4.0 applications 3 litre container with handle made of highly transparent PET on a xBLOW 607D Bekum extruder, extrusion head and...

Open the catalog to page 7

Pharma / Cosmetics / Chemical SAFE. ECONOMICAL. INDIVIDUAL. PERFORMANCE CHARACTERISTICS FOR THE PRODUCTION OF HIGH QUALITY PHARMACEUTICALS PACKAGING: Fully-electric blow moulding machines for use in clean rooms PHARMACEUTICAL PACKAGING Machines designed to cGMP (FDA) Bekum is the right Company to contact for pharmaceutical packaging with sterile production under clean-room conditions. Our special machine concept for “sterile” blow moulding meets pharmaceutical industry quality requirements. It includes individual, tailor-made machine solutions for hygienic packaging, and our “sterile” blow...

Open the catalog to page 8

Pharma / Cosmetics / Chemical COSMETICS In addition to the functional packaging requirements, cosmetic products also have particular requirements for their look and feel. Our experts are happy to provide you with in-depth advice when developing individual bottle designs which can still be produced economically. Our co-extrusion concept allows the contents to be protected, and also allows smooth surfaces to be produced on the outside of the bottle - which allows optimum brand presentation. Cosmetic products are technically demanding in terms of optic, function and safety. CHEMICAL From...

Open the catalog to page 9

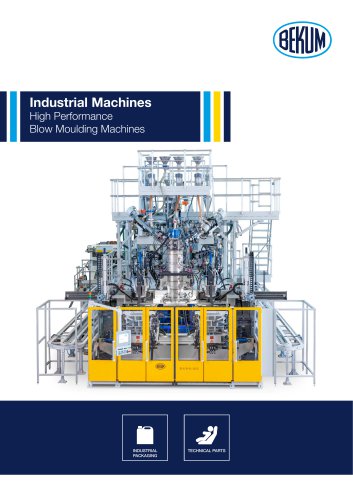

Industrial Packaging BEKUM´S MACHINES OFFER ULTIMATE FLEXIBILITY INDUSTRIAL PACKAGING Bekum’s innovative blow moulding systems are characterised by their practically unlimited flexibility when moulding containers between 5 and 3,000 litres. Opportunities include the standard container shapes, as well as optional transparent visibility stripes or consumer friendly handles, such as the “anti-glug” function, which allows an optimum, constant flow when emptying the container. In addition, our blow moulding systems offer constant high outputs, excellent container quality, and reproducible wall...

Open the catalog to page 10

Industrial Packaging THE COMPACT BEKUM BLOW MOULDING SYSTEM FOR ARTICLES OF UP TO 30 LITRES OFFERS: Special configuration for ultimate production security for 20 to 30 litre container production, using mono extrusion, tri-extrusion and co-extrusion for standard, dual and high-speed production Tried-and-trusted, long-lasting and flexible machine concept et al “top/bottom calibration” Available with energy-efficient electrical and classic hydraulic drive technology Excellent reproducibility in production, thanks to the use of state-of-the-art controls Optional with internal thread and cooling...

Open the catalog to page 11All Bekum Maschinen Fabriken catalogs and technical brochures

-

Packaging Machines

8 Pages

-

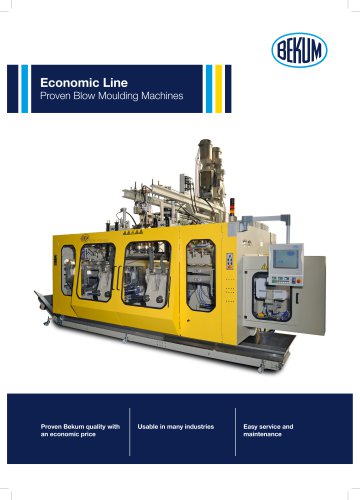

Economic Line

2 Pages

-

Multi-Cavity

2 Pages

-

Industrial Machines

8 Pages

-

Co-Extrusion

12 Pages