Catalog excerpts

Automated Warehouse

Open the catalog to page 2

The automated three-dimensional warehouse, also known as automated three-dimensional storage, is a new concept emerging in logistics and warehousing. Through the management system to coordinate and control the storage equipment, the high-level space utilization of the warehouse can be rationalized, and the automation of outbound and outbound operations can be achieved. In the application of the storage system, the land cost be saved, the cost of human resources can be reduced, and the storage automation, intelligentization, and information management can be realized, aims. ^Information...

Open the catalog to page 3

Product display Smart Factory Industrial Internet+: Remote Monitoring, Big Data, Cloud Computing, Remote Upgrade; Smart Transport, Intelligent Storage

Open the catalog to page 4

\W Automated Warehouse Automated warehouse, also known as automatic storage picking system A system for depositing and withdrawing materials using mechanical facilities apj computer management controP ^sterns. High-level shelves, stacker cranes, shuttles, automatic sorting systems, automatic transfer systems into and out of libraries, and peripheral -facilities-andequipment.V

Open the catalog to page 6

Make full use of the vertical space of the warehouse, so that the storage capacity per unit area is much larger than the ordinary single-storey warehouse, generally 4 to 7 times that of a single-storey warehouse. The world's tallest warehouse can reach more than 40 meters, more than 100,000 cargo spaces

Open the catalog to page 7

Automated warehouse features The three-dimensional warehouse adopts a roadway stacker (shuttle), and the traveling speed is high. With the help of computer control, the cargo handling in the cargo warehouse can be completed without errors. The efficiency of cargo handling is much higher than that of general warehouses, o Roadway stacker travel speed is 80~120M/min, lifting speed is 15~25m/min •••••

Open the catalog to page 8

Disadvantages of automated warehouses A. The structure is complex, there are many supporting facilities, and the investment in infrastructure and equipment required is large; B. Shelf installation accuracy is high, construction is difficult, and construction period is long; C. The variety of stored goods is subject to certain restrictions. Different types of shelves are only suitable for different storage items. Therefore, once the automated warehouse is completed, it is difficult to update the system.

Open the catalog to page 9

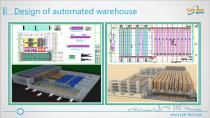

Design of automated warehouse

Open the catalog to page 10

Automated warehouse evaluation

Open the catalog to page 11

Automated warehouse manufacturing

Open the catalog to page 12

Automated warehouse installation

Open the catalog to page 13

Single machine equipment for automated warehouse 5 ed utomat A use Wareho •堆垛机系统 •立库货架系统 •库端输送系统 •电气控制系统 •管理软件WMS Logistics delivery system •链条输送机 •辊道输送机 •皮带输送机 •升降移载机 •伸缩皮带机 •AGV/RGV •其它输送设备 Various types of hoist •C型提升机 •Z型提升机 •E型提升机 •

Open the catalog to page 14

Automated Warehouse gf-m Wlnh t^y misw Using automated warehouses can produce huge social and economic benefits. High shelf storage Using high-level shelf storage, the storage area can greatly expand to high altitude, making full use of the floor and space of the warehouse, thus saving floor space and improving space utilization. 2. Automatic access AS/RS uses mechanical and automation equipment to run and process quickly, improving labor productivity and reducing the labor intensity of operators. 3. Computer control Computers can reduce errors in cargo handling and information processing,...

Open the catalog to page 15

Pallet type roadway stacker Main specifications 1.height track Upper beam Cargo loading platform (vertical) Fork (left and right) Motor reducer Lower beam ØManual, semi-automatic, stand-alone automatic, online automatic Note: Tailored

Open the catalog to page 16

Box type roadway stacker Main specifications 1.高度

Open the catalog to page 17

Railroad Roadway Stacker The fork mechanism is mounted on the cargo platform and completes the picking and delivery operations through the telescopic movement The device consists of three sections of forks and accessory followers and guides. The gears include gears, racks, sprockets, chains, etc. to ensure smooth picking of goods and prevent damage caused by impact.

Open the catalog to page 18

Railroad Roadway Stacker communication method: As a wireless communication device for a stacker controller and a ground controller or a computer system, infrared signals are transmitted/received. It consists of a pair of two. One is installed LEUZE(德国) on the ground at the origin and the other is mounted on the end of the lower beam of the stacker. The supplier is: LEUZE (Germany)

Open the catalog to page 19

Railroad Roadway Stacker Targeting: Automatic addressing of automated warehouses is to automatically find the location for storing/extracting goods. The address of the space in the same lane is composed of three parameters: the first row of shelves, the first few floors, the left side or the right side. When the automatic warehouse receives the access instruction and access address of the upper management machine, it runs in the direction of the designated location. During operation, sensors installed on the stacker constantly monitor the position information and calculate whether the...

Open the catalog to page 20

Wm-Krm Service

Open the catalog to page 21

仓库管理系统基本模块 帐户、角色、权限、日志、备份与还原、 初始化管理、历史数据清理 物料、托盘、仓库、货位、批号、条码设置、 安全库存、有效期、部门、公司、质检状态 设置 入库单、入库组盘、

Open the catalog to page 22

仓库管理系统特点 友好的人机汉化界面、操作简捷直观、易学,大大降低了用户的培训和支持成本 提供权限控制及日志记录,为系统的安全及追溯提供支持 货位分配支持用户指定、紧急优先、先进先出、先近后远、先低后高、巷

Open the catalog to page 23

Automated warehouse racking 1 Beam type combination shelf Loft shelf 1 st m-ttUBi -mm . «ui it bi mi mm\ m SjJJ fltf'jfw MVT^;f9ViVf n?TijJSSf?! combination shelf Automated warehouse racking 2 • < www.cyb-bot.com

Open the catalog to page 24

► The drive unit is an integrated motor speed reducer • Outgoing/incoming storage conveyors are equipped with contours and tray overload detection devices in place • The frame is welded or bent from cold-rolled steel or better material Q235-C • All devices have manual, online and online automatic control • All devices are equipped with leveling and locking devices > Key part with shape detection device

Open the catalog to page 25

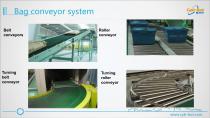

Bag conveyor system Belt conveyors Turning belt conveyor Roller conveyor Turning roller conveyor

Open the catalog to page 27All Beijing Cyberrobot Technology Co. catalogs and technical brochures

-

Automatic Pallet Repository

2 Pages

-

Pallet Conveyor

2 Pages

-

Climbing Conveyor

2 Pages

-

Curve Conveyor

2 Pages

-

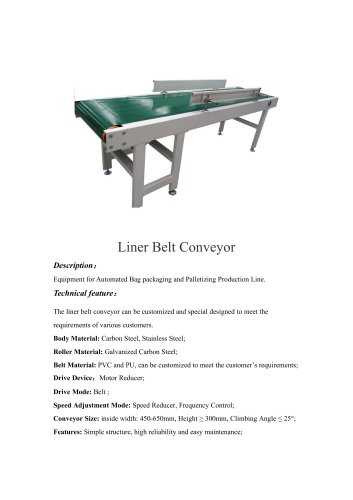

Liner Belt Conveyor

2 Pages

-

Liner Roller Conveyor

2 Pages

-

Weighing Scale

3 Pages

-

Automatic Labeling Machine

2 Pages

-

Metal Detector

2 Pages

-

Automatic Carton Sealer

2 Pages

-

Automatic Bagging Machine

2 Pages

-

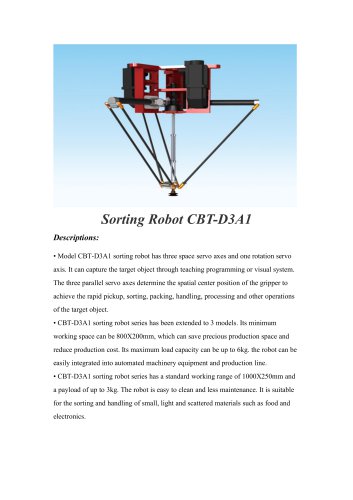

sorting robot CBT-D3A1

3 Pages

-

sorting robot CBT-D2A3

2 Pages

-

Sorting robot CBT-C4A1

3 Pages

-

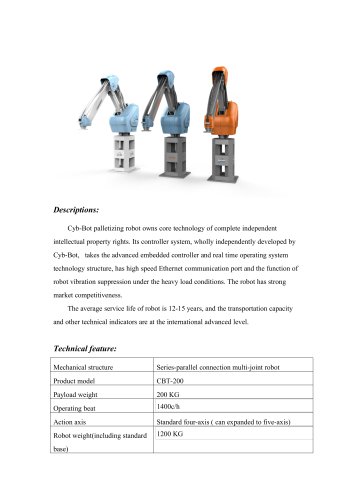

Palletizing robot CBT-200

3 Pages

-

Palletizing robot CBT-90

3 Pages

-

Cyb-Bot 6

30 Pages

-

Cyb-Bot 5

46 Pages

-

Cyb-Bot 4

1 Pages

-

Cyb-Bot 3

1 Pages

-

Cyb-Bot 2

49 Pages

-

Cyb-Bot

16 Pages