Catalog excerpts

Food Program Introduction and Requirements Research Beijing cyberrobot Te c h n o l o g y C o . , L t d .

Open the catalog to page 1

一、Industry Profile 二、Typical Case 三、Major equipment 1.Conveyor 2.Unpacking machine 3.Packing machine 4.Bagging machine 5.Bag folding machine 6.Sealing machine 7.Baler 8.Shrinking machine 四、requesting research

Open the catalog to page 2

Part I Industry Profile ※ Food Industry Profile ※ Food program scope

Open the catalog to page 3

Industry Profile Ø food industry mainly covers the food manufacturing industries such as convenience foods, beverage drinks, dairy products, condiments, baked goods and confectionery. Ø Food automated packaging production lines mainly include: forming, filling, sealing, unpacking, bagging, packing, labeling, coding, banding, palletizing, winding and a series of processes. 2.Project scope Ø "Post-secondary packaging automation equipment" Ø two processes of initial packaging products (hereinafter referred to as single product) and box handling.Details include: upper box blank, box forming,...

Open the catalog to page 4

Part II Typical Cases ※ Analysis of Cases of Typical Automatic Packaging Production Line in Food Industry

Open the catalog to page 5

ispenser kohot palletizing machine Real stack miSW Bottled automatic packaging production line Applicable products: barrels, such as edible oil Folding lid sealing machine heckweighing machine winding machine Applicable products: round, square, oval, shaped bottles, etc

Open the catalog to page 6

Automatic folding seeling machine Automatic stacker mm Bag automatic packaging production line Applicable products: bags, such as puffed foods, seeds, peanuts, sugar, salt, infusion bags and other soft bags. Automatic palletizing machine Automatic box opening machine Automatic packrng machine Pillow type packing machine 6

Open the catalog to page 7

Tray warehouse Bottle automatic packaging production line Applicable products: cans, mineral water, beer, glass bottles, beverages and other bottled products Tablet wrapping machine Shrink packaging machine Automatic palletizing machine Product regular delivery

Open the catalog to page 8

C a s e 4 Box automatic packaging production line Applicable products: boxed products such as biscuits and puffed foods, and large boxed products such as dairy products.。

Open the catalog to page 9

The third part of the main equipment ※ The main equipment introduction and application case in the food program.。

Open the catalog to page 10

Roller conveyor Suitable for cartons, baskets, trays, etc. ••••• _• •_ Belt conveyors Widely applicable; Material: rubber, PVC, PU, etc.; Chain conveyor For trays, etc.

Open the catalog to page 11

Chain conveyor Chain conveyor Suitable for glass bottles, PET bottles, cans, etc.; Suitable for bulk materials, glass bottles, PET bottles, cans, etc.

Open the catalog to page 12

Flexible chain conveyor A. Lightweight combined three-dimensional conveyor system; using aluminum alloy frame, plastic steel conveyor chain. B. Lightweight, compact, standard modular structure; simple installation and disassembly, low noise. C. Smooth and smooth conveying surface, small friction, small turning radius, and strong climbing ability. D. Suitable for all kinds of cans, bottles and all types of carton packaging. 0 r . . -i

Open the catalog to page 13

2.Unpacki n g m a c h i n e A. The automatic box opening machine is an assembly line device used for automatic unpacking of large-volume cartons, automatic folding of lower covers, and automatic sealing of bottom tapes. All the machines use PLC+display control, which is convenient for operation and is an indispensable equipment for automatic scale production. B. It is divided into vertical box opening machine and horizontal box opening machine according to the way of opening box. ※Vertical out of the box process: Vertical box opening speed: 10 boxes/minute; 15 boxes/minute ※Horizontal open...

Open the catalog to page 14

2.Open_box machine (vertical Low speed vertical open box machine Unpacking capacity: 10 cases/minute i Carton temporary storage: 100pcs (1000mm) Carton size: L: 250-450 W: 150-400 H: 100-400mm (Minimum specifications cannot exist together) Power usage: 220V 1$ 200W Required air pressure: 6kg/cm2 Air consumption: 450NL/min Machine size: L2000X W1900XH1450mm Tape size: 48, 60, 75mm Mechanical weight: 450Kg High speed vertical open box machine Unpacking capacity: 15 boxes/minute Carton temporary storage: 100pcs (1000mm) Carton size L: 200~400 W: 150~350 H: 100~350mm (Minimum specifications...

Open the catalog to page 15

(horizontal type) Low-speed horizontal open box machine Unpacking capacity: 30 boxes/minute Carton temporary storage: 80pcs (800mm) Carton size: L:240-510 W:190-400 H:120-400mm (Minimum specifications cannot exist together) Power usage: 380V 3$ 746W Required air pressure: 5kg/cm2 High-speed h°riz°ntal open box machine Air consumption: 300NL/min Unpacking speed: 50 boxes/minute Machine size: L2372XW1210XH1820mm Carton temporary storage: 8°pcs (1000mm) Tape Size: 2”, 2.5” Carton temporary storage: L: 250-450x W: 150-400x H: (Minimum specifications cannot exist together) Power usage:...

Open the catalog to page 16

3.Packing machine AA. A boxing machine is a device that semi-automatically or automatically loads a product into a shipping package. B. Its working principle is to put the product into the box according to a certain arrangement and quantity (corrugated cardboard boxes, plastic baskets, trays, etc.). C. In the rear automatic packaging line, the packing machine is the core of the entire line system operation. D. According to the different packing methods, there are generally five types: catch, clamp, suction, drop, and push.

Open the catalog to page 17

3.Packing machine (falling type packing machine) a) Packing speed: 10-15 boxes/minute b) Packing Type: 3X4 (customized according to customer's requirements) c) Packaging material: corrugated boxes d) Carton size: L200-500X W150-400XH100-300mm e) Suitable products: glass bottles, plastic bottles, soft bags f) Power supply: 380 V 50Hz, 20KW g) Air pressure and air consumption: 0.6Mpa, 800L/min The drop type packing machine has a mesh belt conveyor to arrange the bottles neatly, and is divided into six rows, five rows or four rows (according to the different packing methods), the...

Open the catalog to page 18All Beijing Cyberrobot Technology Co. catalogs and technical brochures

-

Automatic Pallet Repository

2 Pages

-

Pallet Conveyor

2 Pages

-

Climbing Conveyor

2 Pages

-

Curve Conveyor

2 Pages

-

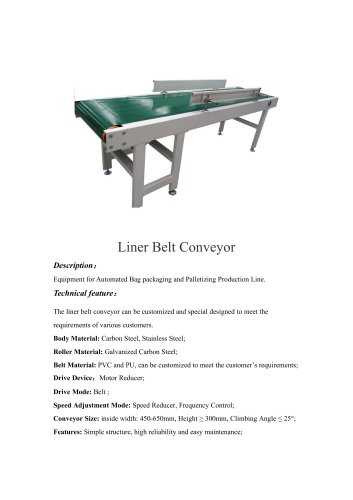

Liner Belt Conveyor

2 Pages

-

Liner Roller Conveyor

2 Pages

-

Weighing Scale

3 Pages

-

Automatic Labeling Machine

2 Pages

-

Metal Detector

2 Pages

-

Automatic Carton Sealer

2 Pages

-

Automatic Bagging Machine

2 Pages

-

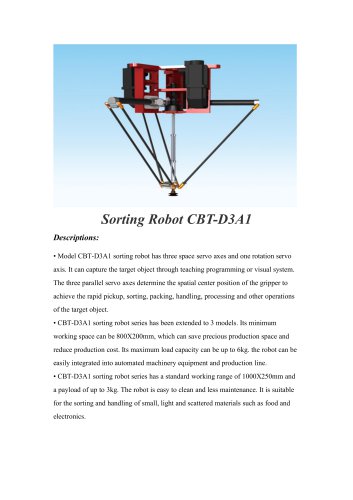

sorting robot CBT-D3A1

3 Pages

-

sorting robot CBT-D2A3

2 Pages

-

Sorting robot CBT-C4A1

3 Pages

-

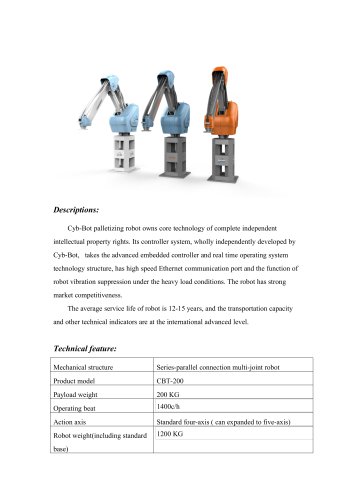

Palletizing robot CBT-200

3 Pages

-

Palletizing robot CBT-90

3 Pages

-

Cyb-Bot 7

42 Pages

-

Cyb-Bot 5

46 Pages

-

Cyb-Bot 4

1 Pages

-

Cyb-Bot 3

1 Pages

-

Cyb-Bot 2

49 Pages

-

Cyb-Bot

16 Pages