Catalog excerpts

Global supplier of intelligent storage and information system integration

Open the catalog to page 1

Three-dimensional storage development history 1.World history • The production and development of stereoscopic warehouses after the Second World War was the result of production and technological development. • In the early 1950s, a solid warehouse with bridge-type stacking cranes emerged in the United States. • 50's and early 60's, drivers appeared to operate a three-dimensional warehouse for stacking cranes.。 www.cyb-bo

Open the catalog to page 2

Ill • In 1963, the United States took the lead in the use of computer control technology in elevated warehouses and established the first computer-controlled warehouse. Since then, automated warehouses have been rapidly developed in the United States and Europe, and special disciplines have been formed. • In the mid-1960s, Japan began to establish physical warehouses, and the pace of development grew faster and faster, becoming one of the countries with the most automated warehouses in the world today. www.cyb-bot.com

Open the catalog to page 3

Three-dimensional storage development history 2.Domestic history • In 1963, it developed the first bridge-type stacker crane—Beijing Lifting and Transportation Machinery Research Institute. • In 1973, it began to develop China's first computer-controlled automated three-dimensional warehouse (15 meters high, responsible for lifting the Ministry of Machinery) and was put into operation in 1980 (Zhengzhou Textile Machinery Factory). • The main industries for automated overhead warehouse applications include machinery, metallurgy, chemical industry, aerospace, electronics, medicine, food...

Open the catalog to page 4

[([Three-dimensional storage development history 2.Domestic history

Open the catalog to page 5

Three-dimensional storage development history Cyb-Bat sism • In 2003, about 30 to 40 seats of automated three-dimensional libraries were contracted. Among them, the independent AS/RS automated threedimensional library accounts for about 90% of the total, and it accounts for about 10% of other logistics systems such as logistics distribution centers. • The total volume of automated library construction in 2005 was basically the same as in 2004. According to incomplete statistics, more than 40 automated three-dimensional libraries were built throughout the year. The total output value is...

Open the catalog to page 6

Three-dimensional storage development history 3.Domestic Development Status • At the end of 2007, there were more than 600 stores in the country's automated warehouse. In 2007, about 100 automated warehouses were built in China. • In 2010, there were nearly 200 autostereoscopic libraries built in China, and more than 1,000 different types of railroad track stacker products were produced. The total output value of autostereoscopic libraries exceeded RMB 1.5 billion. By the end of 2010, nearly 2,000 automated threedimensional libraries had been built across the country, and more than 1,500...

Open the catalog to page 7

Three-dimensional storage development history 4.Domestic development forecast (1)Demand trends: The market demand for military, dairy, tobacco, low-temperature food, railway, subway, manufacturing and other industries increased. Foreign companies such as India and Thailand started to import Chinese stereoscopic warehouses. This has created opportunities for domestic companies.。 (2)Demand background: The country has determined the red line of land of 1.5 million mu of land per million mu of cultivated land. Under this major policy, due to the high storage rate of solid libraries, the demand...

Open the catalog to page 8

Three-dimensional storage development history 4.Domestic development forecast (4)Large-scale production of large manufacturing enterprises, the necessity of inventory adjustment in production leads to the necessity of the development of threedimensional library. (5)Enterprises that seek to minimize the number of employees in their enterprises will accelerate the change in labor-intensive production methods. An automated warehouse can save 30% - 90% of the management staff, and at the same time help solve employees' insurance benefits, labor disputes and other issues. (6)Information...

Open the catalog to page 9

The composition of an automated warehouse

Open the catalog to page 10

The composition of an automated warehouse The overall composition of an automated warehouse

Open the catalog to page 11

The composition of an automated warehouse Automated warehouse hardware composition 1 Civil Engineering and Auxiliary Facilities. According to the scale of the warehouse and the functional requirements of the warehousing system, the architects should design according to the relevant national standards according to the geological situation. 2 Auxiliary Facilities - Lighting In order for the management, operation and maintenance personnel in the warehouse to perform normal production activities, there must be a better lighting system, especially in the peripheral work area and auxiliary area....

Open the catalog to page 12

The composition of an automated warehouse Automated warehouse hardware composition 1.Auxiliary facilities - fire fighting According to China's "Code for Fire Protection in Architectural Design" (GB 50016-2014), the design is based on the nature of the items stored, and specific fire protection plans and measures are determined. www.cyb-bot.com

Open the catalog to page 13

The composition of an automated warehouse Cyb-Bot sism Most automated fire protection systems in automated warehouses use automatic fire protection systems. Automatic fire control system can be divided into direct control type and distributed control type according to different topological structures. The basic composition and working principle are shown in the figure:

Open the catalog to page 14

n The composition of an automated warehouse Automated warehouse hardware composition 1. auxiliary facilities - ventilation and heating protection The requirements for ventilation and heating are based on the conditions of the stored items. The temperature inside the automated warehouse is generally -5° C to 45 ° C. It is usually implemented by roofs and side fans, top and side ventilation windows, central air conditioning, and heating. Requires environmental protection for storage of warehouses that emit hazardous gas products, and appropriate treatment of harmful gases before discharging...

Open the catalog to page 15All Beijing Cyberrobot Technology Co. catalogs and technical brochures

-

Automatic Pallet Repository

2 Pages

-

Pallet Conveyor

2 Pages

-

Climbing Conveyor

2 Pages

-

Curve Conveyor

2 Pages

-

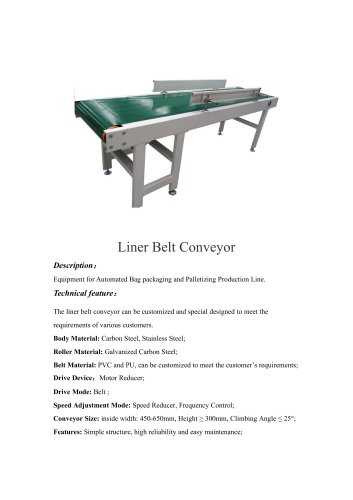

Liner Belt Conveyor

2 Pages

-

Liner Roller Conveyor

2 Pages

-

Weighing Scale

3 Pages

-

Automatic Labeling Machine

2 Pages

-

Metal Detector

2 Pages

-

Automatic Carton Sealer

2 Pages

-

Automatic Bagging Machine

2 Pages

-

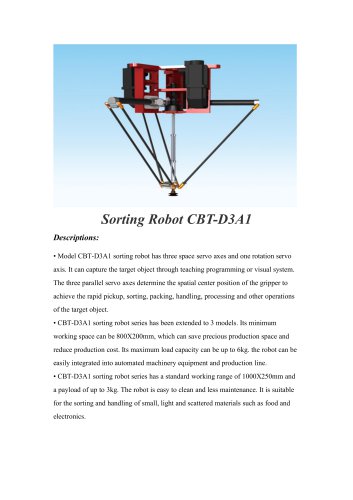

sorting robot CBT-D3A1

3 Pages

-

sorting robot CBT-D2A3

2 Pages

-

Sorting robot CBT-C4A1

3 Pages

-

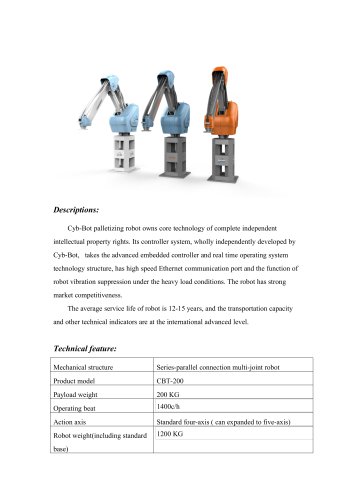

Palletizing robot CBT-200

3 Pages

-

Palletizing robot CBT-90

3 Pages

-

Cyb-Bot 7

42 Pages

-

Cyb-Bot 6

30 Pages

-

Cyb-Bot 4

1 Pages

-

Cyb-Bot 3

1 Pages

-

Cyb-Bot 2

49 Pages

-

Cyb-Bot

16 Pages