Catalog excerpts

Polypropylene is one of the most preferred thermoplastics in different industries, especially in the automotive sector. However, high level of reinforcement was always a problem in filament making. PP GF30 contains special glass fibers that are designed for filament making and 3D printing. This will ensure the printed objects are functionally working, under certain temperature and mechanical loads. Thanks to its UV-resistance, it is more suitable than any other PP based filament for applications that are directly exposed to sunlight. PP inherently uptake lower moisture than PA. In combination with high level of glass fiber reinforcement, PP GF30 is a filament of selection for exceptional working environments. PP GF30 combines great features that couldn’t be combined before: printing stiffer parts with UV resistance is now possible. PP GF30 is ideal when extreme stiffness is required in humid environments.

Open the catalog to page 1

PPGF30 - Technical information including: GUIDELINE FOR PRINT SETTINGS Nozzle temperature Fiber reinforced PP strapping tape (e.g. Scotch Extreme) Layer height Shell thickness Print speed Additional information Hardened or Ruby nozzle, diameter ≥ 0.6 recommended Settings are based on a 0.6 mm nozzle MATERIAL PROPERTIES Test Method Melt temperature Glass transition temperature Water solubility Mechanical Properties / TENSILE TEST / IMPACT TEST / FLEXURAL TEST Infill

Open the catalog to page 2All Bcn3d catalogs and technical brochures

-

PAHT-CF15

2 Pages

-

BCN3D Sigma D25

3 Pages

-

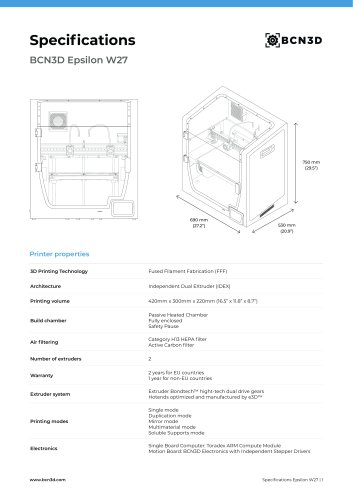

BCN3D Epsilon W27

3 Pages

-

BCN3D Epsilon W50

3 Pages