Catalog excerpts

Direct Drives be in motion

Open the catalog to page 1

Datei Ansichten t Darstellung |*' Konfigorationsdaten § mfe

Open the catalog to page 2

Added value for our customers Our goal is to enable more flexibility in your machine design and ensuring your machine users the necessary productivity and efficiency in production, thereby giving your machines a competitive edge. That is why the focus of our development is not just the entire system of a machine, but also the added value that we make available to our customers with the modularization of machines, the scalability of components and flexible technology blocks. www.baumueller.com

Open the catalog to page 3

With a torque of up to 32,000 Nm, the DST range from Baumuller meets the highest demands in direct-drive technology. The high-torque servo motor is therefore ideally suited for applications such as: © Plastics machines © Rotary tables or swivel axis © Printing machines © Press technology © Winders © Wire-drawing machines © Stretching units © Machine tools © Woodworking machines © Special machines © Ship propulsion

Open the catalog to page 4

Baumüller is a pioneer in the field of direct drive technology and has been a major player on this market since 1991. With over 40 subsidiaries worldwide, Baumüller is always close by, no matter where your machine is to be installed. Conventional solution Make the most of the flexibility and innovation that our experts at Baumüller offer for customizing system concepts to meet your requirements. These offerings include the suitable water-cooled servo drives, thrust bearings, and appropriate shaft options — everything from one single source. Direct drive technology Pulley Standard motors /...

Open the catalog to page 5

Direct drive technology compared to the combined motor/gearbox Combined motor/gearbox Direct drives solution

Open the catalog to page 6

Many market leaders rely on high-torque motors with an integrated thrust bearing from Baumuller as the drive for their extruder screw. This integrated drive approach provides many advantages for the mechanical engineer with regard extrusion technology requirements. Reduction of operating and energy costs © No gearbox losses © Gearbox maintenance no longer necessary © Close adding of drives possible Your advantage Increased cost-efficiency due to improvement in overall economic and ecological benefits. Improved power density Less installation space required due to high integrated design...

Open the catalog to page 8

DST motors for injection molding machines Many leading manufacturers of injection molding machines are increasingly replacing their hydraulics with direct drive solutions from Baumüller. Baumüller draw from our extensive experience in your market segment and develop, together with you, systems with very high energy efficiency and productivity. Increased productivity and reduced energy costs No system losses due to hydraulic fluids that are converted into wasted heat No heating of the system, meaning there is no need to use a fan motor for temperature control Your advantage Lower energy...

Open the catalog to page 9

Comparison of energy flow in injection moulding Fully hydraulic machines Torque motor Plastic melt Servo controller Reduction of cycle times Due to limited performance capability of the hydraulic system, unlocking can not begin until dosing is complete. Control system Hydraulic motor Control system Plastic melt Hybrid and electrical machines Concurrent functions result in a significantly shorter cycle time of 30% (calculated on the example of manufacturing a drinking cup). Cycle previously (fully hydraulic machines) Close tool Lock tool Nozzle system Inject Cool Dosing Unlock tool Open tool...

Open the catalog to page 10

DST motors for printing machines Baumüller was the first system manufacturer in the printing machine sector to perform pioneering work with direct drive technology. In the past, it was more common to drive synchronized rotating cylinders using positive coupling via hard gearing. Increasingly more manufacturers are now relying on direct drive technology with electronic synchronization from Baumüller and are profiting from the advantages. Increased precision Improved control and positioning precision as well as load stiffness because gearbox and gear connections are no longer required....

Open the catalog to page 11

Very good smooth running characteristics Energy-efficiency is maintained through wide speed/load range Suitable for sophisticated direct drive technology High torque at low velocities Low-noise Water cooling in a stainless steel design Compact and robust design Smooth housing surface - easy to keep clean Permanent field high-torque motors IP54 type of protection Encoder: Resolver, SinCos encoder (option) Other encoders on request Water-cooled variants of the DST high-torque motors are available. Type Pn nN Mo Momax The values quoted are maximum values. * In preparation,...

Open the catalog to page 12

Property Product advantage Customer benefits

Open the catalog to page 13

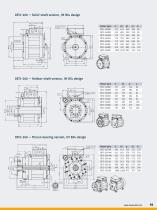

DST2-135 - Solid-shaft version, IM B14 design DST2-135 ! Hollow-shaft version, IM B14 design DST2-135 ! Thrust-bearing version, IM B34 design

Open the catalog to page 15

1) The maximum permissible operating speed for thrust bearing motors is 1000 min-', from 300 min-' it is obligatory to use an oil cooler. 2) The maximum permissible operating speed for hollow shaft motors is 1000 min-1.

Open the catalog to page 16

DST2-200 — Solid-shaft version, IM B14 design Motor type k DST2-200 — Hollow-shaft version, IM B14 design Motor type DST2-200 — Thrust-bearing version, IM B34 design Motor type

Open the catalog to page 17

DST2-260 - Solid-shaft version, IM B14 design DST2-260 ~ Hollow-shaft version, IM B14 design DST2-260 ~ Thrust-bearing version, IM B34 design

Open the catalog to page 19

The maximum permissible operating speed for thrust bearing motors is 500 min-', from 300 min-' it is obligatory to use an oil cooler. The maximum permissible operating speed for hollow shaft motors is 500 min-1.

Open the catalog to page 20

1) The maximum permissible operating speed for thrust bearing motors is 500 min-1, from 300 min-' it is obligatory to use an oil cooler. 2) The maximum permissible operating speed for hollow shaft motors is 500 min-1.

Open the catalog to page 21

DST2-315 — Hollow-shaft version, IM B14 design

Open the catalog to page 22All Baumüller Nürnberg GmbH catalogs and technical brochures

-

Baumüller Marine Solutions

20 Pages

-

b maXX PCC04

2 Pages

-

Imagebroschüre

16 Pages

-

b maXX

48 Pages

-

Automation

48 Pages

Archived catalogs

-

Mobile Drives

24 Pages

-

Volume reduced

2 Pages

-

BAS-Blech

1 Pages

-

Ubiquity

6 Pages

-

Servo pumps

2 Pages

-

3- and multi-axis handling

8 Pages

-

b maXX

44 Pages

-

Disc Motors

20 Pages

-

Motors

32 Pages

-

Baumüller at a glance

8 Pages

-

Safety Lifecycle Navigator

64 Pages