Catalog excerpts

Tilting rotary furnace KTO 5 - KTO 20 Description The tilting rotary furnace is the key technology in state-of-the-art aluminium recycling plants, it is used for melting lumpy and contaminated scraps, particularly dross, chips and UBCs. Short charging times combined with low specific energy consumption and reduced salt addition result in a considerable increase of productivity and efficiency of the plant. Technical data theor. effective furnace capacity: 5 to 20 tons theor. melting output: 1 to 5 t/h Salt factor: 0.3 to 0.6 Average gas consumption : 25 to 45 Nm³/t (raw material + salt) Burner output gas-O² burner: 1-6 MW Number of rotation of furnace: 1 to 9 rotations/min Clearance of door opening: 900-2,350 mm Characteristics State-of-the-art gas-oxygen-air-burner Two-part multifunctional door, can be opened individually, with integrated burner adjustment, slag retainer and swivelling flue gas channel. Aluminium tapping with closed door resulting in low energy loss and low oxidation of the melt Perfect view for the operator during burner operation due to individually opening wings of the door Perfect temperature monitoring Reduction of oxidation atmosphere by continuous temperature adjustment Short melting times and low temperature loss due to efficient furnace insulation Suitable for ferrous scraps Permanent monitoring of bearing temperature Remote maintenance module integrated into the control system Bartz Maschinenbau GmbH | Robert-Bosch-Straße 14 + 18 | 56727 Mayen Tel: +49 2651 49 30 - 0 | Fax: +49 2651 48 75 8 | info@bartz-maschinenbau.de | www.bartz-maschinenbau.de

Open the catalog to page 1All BARTZ MASCHINENBAU GMBH catalogs and technical brochures

-

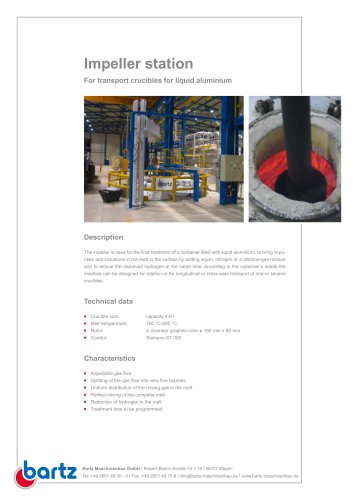

Impeller station

1 Pages

-

Street transport crucible

1 Pages

-

Immersion heater

1 Pages

-

Crucible heating station

1 Pages

-

Desox casting machine

1 Pages

-

Granulating plant

1 Pages

-

Stacking machine

1 Pages

-

Tilting mechanism

1 Pages

-

Impeller station

1 Pages

-

Street transport crucible

1 Pages

-

Immersion heater

1 Pages

-

Crucible heating station

1 Pages