Catalog excerpts

Tilting melting and holding furnaces Series WHO Description This furnace type is used for refining and casting aluminium melts in casting machines and transport crucibles. Bath treatment is carried out either by means of stirring gas lances or by porous plugs. Technical data Capacity: Melting capacity: Bath depth of: Door: Burner: Furnace weighing: 10-50 t liquid aluminium 1-5 t/hour up to 1,200 mm hydraulically displaceable charging door to be opened allover the width of the furnace. regenerative burner pairs up to 4,5 MW output per burner measuring accuracy 100 kg Characteristics Hydraulically operated charging and cleaning doors over the complete furnace width. Optimal door insulation by means of flanged cast plates. Effective regenerative burner pairs ensure CO2 reduction. To save space flue and exhaust gas fans, fittings and control lines are installed on the furnace roof. Electrically adjustable exhaust gas valves ensure constant furnace pressure. High-quality refractory lining guarantee long working live and low maintenance costs. Melt cleaning by means of hydraulically immersing graphite lances or porous plugs. Compact design with self-supporting roof construction. Easy cleaning at alloy change. Remote maintenance module integrated into the control system. Optional: interface to company network for recording consumption data. Bartz Maschinenbau GmbH | Robert-Bosch-Straße 14 + 18 | 56727 Mayen Tel: +49 2651 49 30 - 0 | Fax: +49 2651 48 75 8 | info@bartz-maschinenbau.de | www.bartz-maschinenbau.de

Open the catalog to page 1All BARTZ MASCHINENBAU GMBH catalogs and technical brochures

-

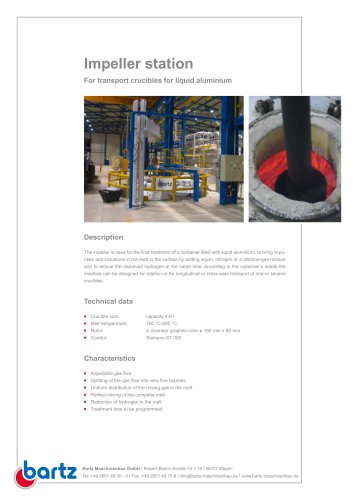

Impeller station

1 Pages

-

Street transport crucible

1 Pages

-

Immersion heater

1 Pages

-

Crucible heating station

1 Pages

-

Desox casting machine

1 Pages

-

Granulating plant

1 Pages

-

Stacking machine

1 Pages

-

Tilting mechanism

1 Pages

-

Tilting rotary furnace

1 Pages

-

Impeller station

1 Pages

-

Street transport crucible

1 Pages

-

Immersion heater

1 Pages

-

Crucible heating station

1 Pages