Catalog excerpts

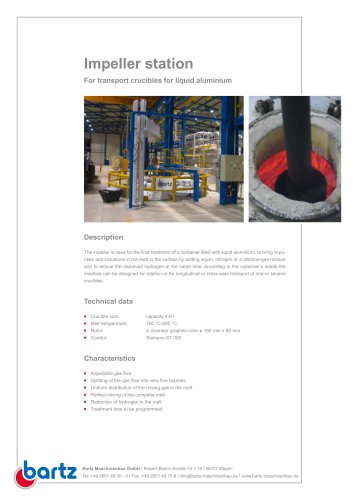

Impeller station For transport crucibles for liquid aluminium Description The impeller is used for the final treatment of a container filled with liquid aluminium, to bring impurities and inclusions in the melt to the surface by adding argon, nitrogen or a chlorine-gas-mixture and to reduce the dissolved hydrogen at the same time. According to the customer’s needs the machine can be designed for rotation or for longitudinal or cross-wise transport of one or several crucibles. Technical data Crucible size: Melt temperature: Rotor: Control: capacity 4-6 t 760 °C-800 °C 4 chamber graphite rotor ø 190 mm x 80 mm Siemens S7-300 Characteristics Adjustable gas flow Splitting of the gas flow into very fine bubbles Uniform distribution of the rinsing gas in the melt Perfect mixing of the complete melt Reduction of hydrogen in the melt Treatment time to be programmed Bartz Maschinenbau GmbH | Robert-Bosch-Straße 14 + 18 | 56727 Mayen Tel: +49 2651 49 30 - 0 | Fax: +49 2651 48 75 8 | info@bartz-maschinenbau.de | www.bartz-maschinenbau

Open the catalog to page 1All BARTZ MASCHINENBAU GMBH catalogs and technical brochures

-

Street transport crucible

1 Pages

-

Immersion heater

1 Pages

-

Crucible heating station

1 Pages

-

Desox casting machine

1 Pages

-

Granulating plant

1 Pages

-

Stacking machine

1 Pages

-

Tilting mechanism

1 Pages

-

Tilting rotary furnace

1 Pages

-

Impeller station

1 Pages

-

Street transport crucible

1 Pages

-

Immersion heater

1 Pages

-

Crucible heating station

1 Pages