Catalog excerpts

Crucible heating station with gas burner for aluminium transport crucibles Description This machine is used to heat transport crucibles for liquid aluminium with a capacity of 5-15 t. The gas burner is pneumatically lowered onto the crucible, the control system of the machine then adjusts the pre-set crucible temperature automatically. It is also possible to run individual heating curves. In that case a thermostatic control installed in the lining is used to monitor the temperature Technical data Dimensions l x w x h: Burner output min./max.: Heating speed : Electric connection load : Control system: 3.6 x 2.2 m x 3.4 m (incl. transport crucible) 40 kW / 360 kW (optional recuperative burner) max. 10 degrees per hour (maintaining temperature) 7 kW Siemens S7-300 with touch panel Characteristics Energy efficient burner technology for different heating media (natural gas or propane gas burner, recuperative burner on demand) Tried and tested solid design of the mechanic system with integrated gas/air control lines System control by means of PLC Operation via operating panel DVGW certified technology Continuous burner adjustment Optional programmes for pre-heating and holding the temperature Programme controlled drying of crucibles through definable heating curves Optimal recording of consumption and measurement data in a central database Bartz Maschinenbau GmbH | Robert-Bosch-Straße 14 + 18 | 56727 Mayen Tel: +49 2651 49 30 - 0 | Fax: +49 2651 48 75 8 | info@bartz-maschinenbau.de | www.bartz-maschinenbau.de

Open the catalog to page 1All BARTZ MASCHINENBAU GMBH catalogs and technical brochures

-

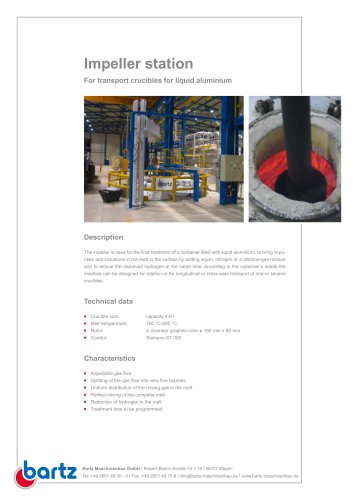

Impeller station

1 Pages

-

Street transport crucible

1 Pages

-

Immersion heater

1 Pages

-

Crucible heating station

1 Pages

-

Desox casting machine

1 Pages

-

Granulating plant

1 Pages

-

Stacking machine

1 Pages

-

Tilting mechanism

1 Pages

-

Tilting rotary furnace

1 Pages

-

Impeller station

1 Pages

-

Street transport crucible

1 Pages

-

Immersion heater

1 Pages