Catalog excerpts

Instruction, Use and Maintenance Manual MIXPROOF VALVE Bardiani Valvole S.p.A. via G. di Vittorio, 50/52 - 43045 Fornovo di Taro (PR) - Italy tel. +39 0525 - Fax 0525 3408 bardiani@bardiani.com - www.bardiani.com (Translation of the original instructions)

Open the catalog to page 1

MANUAL REVISION

Open the catalog to page 2

Safety,Warning and Mandatory Signs 1.1 Operator training General safety warnings Electrical connections Technical data Checking / Unpacking / Lifting Installation Operation Troubleshooting Cleaning Disposal Maintenance General maintenance Scheduled maintenance Tools useful for Disassembly/Reassembly Mixproof valve B925 - B925B Diverter 10.10 External Sensor Adjustment

Open the catalog to page 3

INTRODUCTION This “Instruction, Use and Maintenance Manual” has been prepared to provide guidance and recommendations to assist qualified skilled technicians in the understanding, running and maintenance orf the Products supplied. It forms an integral part of the Products supplied and must be read prior to any installation, operation and/or maintenance of all types of valves provided. This manual must be saved for future reference and be kept readily available at the unit. With regards to the use of valves compliant with EU Directive 2014/34/UE (ATEX), consultation of a specific manual is...

Open the catalog to page 4

Safety,Warning and Mandatory Signs 1 Safety,Warning and Mandatory Signs WARNING SIGNS Pictogram Description WARNING General WARNING Hand crushing WARNING Heavy loads WARNING Severe burns WARNING Risk of explosions WARNING Loaded Spring Hazard Notes This tells the person in question that the operation described involves (when not performed in accordance with the relative safety regulations) the risk of personal injury. Exercise caution in executing the procedure Hand crushing hazard Never touch the moving parts if the actuator is supplied with complessed air Exercise caution in executing the...

Open the catalog to page 5

Safety,Warning and Mandatory Signs MANDATORY SIGNS (FOR THE OPERATOR IN CHARGE OF MECHANICAL MAINTENANCE) Pictogram Notes Special instructions must be followed to avoid injury to persons. OBLIGATION General PROTECTIVE GLOVES Use safety footwear to protect against injuries caused by falling objects during maintenance operations (particularly when dismantling parts). SUITABLE CLOTHING SAFETY GLASSES Protective gloves must be available for handling objects which could cause hand injuries or when there is the possibility of coming into contact with harmful substances.. Hard hats must be...

Open the catalog to page 6

Safety,Warning and Mandatory Signs OPERATING SIGNS Pictogram Description PRESS PRESS (release) ELECTRICAL CONNECTION ELECTRICAL DISCONNECTION PNEUMATIC CONNECTION PNEUMATIC DISCONNECTION APPLICATION OF FOODSAFE GREASE APPLICATION OF FOODSAFE GREASE APPLICATION OF MULTIPURPOSE GREASE THREADLOCK APPLICATION ASSEMBLY / DISASSEMBLY SEQUENCE Use of a press Gradual release of the pressure force Electrical connection to the control unit (consult the relative instruction manual). Electrical disconnection from the control unit (consult the relative instruction manual). Connection of the air to the...

Open the catalog to page 7

Safety,Warning and Mandatory Signs 1.1 Operator training All persons who have to work on the valve must be qualified to carry out the relative maintenance tasks. They must be informed as to the possible hazards involved and must observe all the safety instructions set out in this manual. Allow expert personnel only to work on the electrical components.

Open the catalog to page 8

2 Safety 2.1 General safety warnings Intended use Bardiani valves have been exclusively for moving fluids. Prohibited use The valve must not be used: • for any operations different to those described under the heading “Intended Use”, • for handling fluids different to the type specified by the manufacturer and indicated in the valve's technical data; • for moving fluids at different pressures to those envisaged by the manufacturer and indicated in the valve's technical data. Limitations on valve use It is forbidden to: • use the valve in a construction configuration different to the one...

Open the catalog to page 9

Technical data 3 Technical data VALVE DATA Maximum pressure Maximum seal pressure Minimum pressure Storage temperature Material in contact with the product AISI 316L (1.4404). Check the resistance to corrosion in relation to products and detergents Gasket material in contact with the product EPDM, FKM, HNBR and other gaskets on request. Check compatibility with products and detergents Surface finish in contact with the product Ra 0.8 µm. Other finishes available on request Auxiliary washing circuit (B925B) connections ¼” BSP Male M14x1.5 Male for Ø8 pipe ½” Clamp VAPOUR BARRIER DATA...

Open the catalog to page 10

Checking / Unpacking / Lifting 4 Checking / Unpacking / Lifting 1. CHECK: - Check the valve show no signs of damage caused during transport and that it corresponds with the order; - Check the inside of the valve. 2. UNPACKING: The valve packaging is made up of cardboard, wood and plastic. The valve is mainly made up of metal materials. The gaskets are usually made from elastomers. Disposal must be in compliance with local legislation.

Open the catalog to page 11

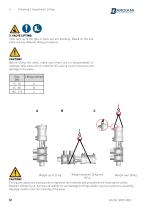

Checking / Unpacking / Lifting 3. VALVE LIFTING: Take care as to the type of valve you are handling. Based on the size there are two different lifting procedures. CAUTION! Before lifting the valve, make sure there are no disassembled or separate valve parts which could fall off causing injury to persons and damage to the valve. Size DN 15--50 65--80 100--125 CAUTION! The figures above are used purely to represent the methods and procedures for hoisting the valves. Bardiani Valvole S.p.A. declines all liability for any damage to things and/or injuries to persons caused by improper and/or...

Open the catalog to page 12

5 Installation 3 1. ELECTRICAL AND PNEUMATIC ENERGY SUPPLY - Use expert personnel for installation/uninstallation operations; - Check that the air pressure and quality are correct (see "Technical Data"); - Check the power supply to the control unit is correct (consult the relative instruction manual). 1 = Opening 2 = Top lift 3 = Bottom lift 2. REDUCING THE STRESS TO WHICH THE VALVE IS SUBJECTED: - Vibrations; - Thermal expansion of the piping; - Excessive welding; - Overload. CAUTION! The seal seats may become deformed or cause valve malfunctioning. 3. CORRECT DIRECTION OF FLOW: Flow in...

Open the catalog to page 13All BARDIANI VALVOLE S.p.a. catalogs and technical brochures

-

BBZS1 BBZS5

14 Pages

-

BBZP

30 Pages

-

BZAW3

8 Pages

-

B935

8 Pages

-

B915PMO

8 Pages

-

BBZS5

60 Pages

-

BBWP1

96 Pages

-

GIOTTO TOP®

37 Pages

-

ZVS

36 Pages