Website:

BANNER ENGINEERING CORP.

Website:

BANNER ENGINEERING CORP.

Catalog excerpts

Leading Edge Detection Solutions

Open the catalog to page 1

What Is Leading Edge Detection? On equipment that moves a product, container, or package, sensors are used to detect the movement or presence of these items. Automated systems use these sensor readings to make critical decisions. Specifically, these applications rely on detecting the leading edge of the item as quickly and as accurately as possible. Types of Leading Edge Detection Challenges of Leading Edge Detection Types of Containers/Packaging Trends in packaging have migrated from boxes to more challenging targets. Polybags, blister packs, envelopes, totes, and tubes are all commonly...

Open the catalog to page 2

Choosing a Banner Sensor Because applications and products vary significantly, there are numerous choices when it comes to leading edge detection. For best results, select a sensor that aligns with your specific needs. Single-Point Leading Edge Detection Small and Flat Object Leading Edge Detection Wide-Beam Leading Edge Detection Through the Roller Leading Edge Detection Robust Array Leading Edge Detection Cost-effective yet powerful, these compact sensors detect boxes, totes, and many other objects. This sensor's short response time and large detection area creates an accurate solution...

Open the catalog to page 3

Polarized Retroreflective Sensors • Polarization assures reliable detection of highly reflective objects • Fast response speed (less than 1 ms) for excellent sensing repeatability • Features bright LED operating-status indicators visible from 360° Q20-2 Polarized Retroreflective Sensors • Rectangular housing for versatile mounting, with M3 threaded inserts and 25.4 mm hole spacing Sensing Range Operating Mode LO/DO selectable switch LO/DO selectable switch *Cabeled models listed. Pigtail and other models available on our website. QS18 All-Purpose Photoelectric Sensors • Universal housing...

Open the catalog to page 4

LX Small and Flat Object Detection Sensors • Large sensing area to provide consistent detection of packages where the leading edge varies • Generates a cross-hatched beam pattern that can detect objects as thin as 1 mm, including envelopes • R esponse times as fast as 0.8 ms allow automated systems to operate at higher line speeds, resulting in increased throughput Response Time Sensing Array Length Output Type 0.8 ms ON-time, 6 ms OFF-time (5 ms OFF-delay) 1.6 ms ON-time, 7 ms OFF-time (5 ms OFF-delay) 2.4 ms ON-time, 7.5 ms OFF-time (5 ms OFF-delay) 3.2 ms ON-time, 8.5 ms OFF-time (5 ms...

Open the catalog to page 5

Q76E Wide-Beam Retroreflective Sensors • Wide-beam retroreflective sensor for reliable leading edge detection of irregular shaped objects or pallets • Visible red beam for simple alignment and bright LEDs for visual indication • Up to 4 m range for mounting flexibility • T wo sensitivity levels for detection of challenging targets such as shrink-wrapped pallets, small objects, and film or perforated packaging • Easy setup and adjustment, with a single push button to select light operate or dark operate (LO/DO) • 250 Hz switching frequency for high-speed production lines • IP67- and...

Open the catalog to page 6

TTR Through The Roller Sensors • R eliable leading edge detection of letters, thin packages, poly bags, totes, boxes, or other products on roller conveyors • M ounts between conveyor roller gap, using standard hex or round side-rail holes (no extra hardware required) or on the T-Slot (with customer-supplied bracket and hardware) • Spring-loaded end caps reduce installation and alignment time for reduced labor costs • B uilt to order with specified length and beam spacing: 200 to 1500 mm (8 to 59 in.) with two to ten sensors for maximum flexibility • R obust aluminum housing, with resistance...

Open the catalog to page 7

SAB Sensor Array Bars • Customizable sensor array bar—different lengths and number of sensors • Robust aluminum housing protects array bars in challenging environments • One M12 connector powers the entire array bar and consolidates all outputs into one • Polarized retroreflective, long-range diffuse, or standard diffuse array bars are available • IEC rating of IP50 • Solid-state bipolar outputs (NPN and PNP) Supply Current Sensing Range Sensing Mode 1 m when using a BRT-THG-2 reflector tape as a target 3 m when using five side-byside BRT-92×92C reflectors or six side-by-side BRT77×77C...

Open the catalog to page 8

More Sensors, More Solutions. Banner Engineering designs and manufactures industrial automation products including sensors, smart IIoT and industrial wireless technologies, LED lights and indicators, measurement devices, machine safety equipment, as well as barcode scanners and machine vision. These solutions help make many of the things we use every day, from food and medicine to cars and electronics. A high-quality, reliable Banner product is installed somewhere around the world every two seconds. Headquartered in Minneapolis since 1966, Banner is an industry leader with more than 10,000...

Open the catalog to page 9All BANNER ENGINEERING CORP. catalogs and technical brochures

-

EG24 Sell Sheet

4 Pages

-

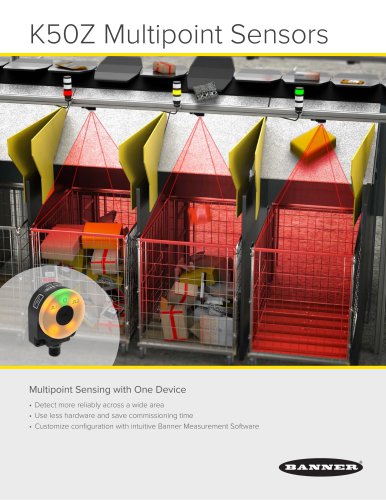

K50Z Sell Sheet

4 Pages

-

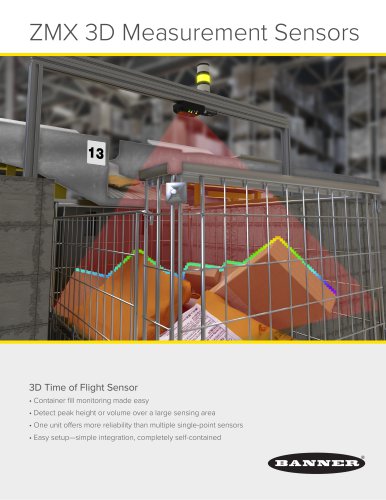

ZMX Sell Sheet

3 Pages

-

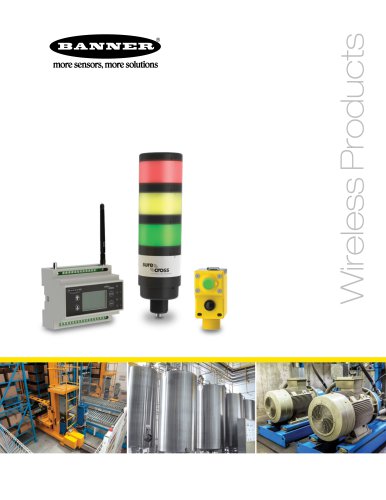

Wirreless Catalogue

92 Pages

-

Safety Solutions

33 Pages

-

New Product Catalog

39 Pages

-

Banner Overview Flyer

3 Pages

-

Banner New Product Flyer

4 Pages

-

AGV Solutions Brochure

3 Pages

-

Car Wash Solutions Brochure

5 Pages

-

Connectivity Solutions Brochure

28 Pages

-

IO-Link Solutions Brochure

20 Pages

-

Laser Sensor Solutions Brochure

11 Pages

-

Lighting and Indication Catalog

55 Pages

-

Monitoring Solutions Brochure

11 Pages

-

Packaging Solutions Brochure

80 Pages

-

Radar Sensor Solutions Brochure

13 Pages

-

Remote IO Brochure

9 Pages

-

Safety Solutions Catalog

33 Pages

-

Snap Signal Brochure

25 Pages

-

Vision Lighting Brochure

17 Pages

-

Leading Edge Brochure

16 Pages