Website:

BANNER ENGINEERING CORP.

Website:

BANNER ENGINEERING CORP.

Catalog excerpts

Automotive Industry Solutions

Open the catalog to page 1

Intelligent Solutions for Complex Processes Facility Management/Energy Saving • Energy savings • Cost savings • Increase efficiency Tier Automotive • Improve production processes • Reduce downtime • Verify product quality Press Shop • Material handling • Stamping and metal fabrication • Sub-assembly Body Shop • Automated welding • Application of adhesives, beads, and sealants • Robot-intensive assembly Paint Shop • Cleaning of finished body • Sealing and adding primer • Painting and top coating • Cure and drying • Material handling and robotics • Casting of engines and transmissions •...

Open the catalog to page 2

Facility Management / Energy Saving Facility management entails a wide variety of responsibilities to keep the production floor humming. Energy management, logistics, and environmental control to name a few. Banner offers simple and effective solutions for the diverse needs of facilities. Indicating Operational Status of Boiler Room Challenge The boiler room can experience malfunctions that cause costly downtime, especially when there is no clear indication of potential problems prior to failure. Solution • K100 Pro Indicator beacons were used to communicate the operational status of each...

Open the catalog to page 3

Tier Automotive Working in close partnership with Tier Automotive components suppliers around the world, Banner Engineering offers automation products that help improve production processes, implement lean strategies, reduce downtime, and verify product quality. Automotive Seat Inspection Challenge In automotive quality inspections, verifying the presence and position of dark parts against an equally dark background is extremely common. For example, many car seats consist of black fabric or leather material with black plastic components, such as levers and buttons to adjust seat height and...

Open the catalog to page 4

Press Shop Banner sensors are used in nearly all areas of the press shop. They ensure stable processes, optimum load, quality inspection, and safeguard operators from injury in this high risk environment. Metal Roll Diameter and Unwind Speed Challenge During metal stamping, it is important to accurately determine the diameter of a roll of sheet metal to prevent the material from running out. Solution • The LE550 laser measurement sensor accurately measures challenging targets like shiny and reflective surfaces. • T he laser sensor's intuitive user interface makes it easy to adjust settings...

Open the catalog to page 5

Body Shop Various components are combined to form a strong vehicle base: the body. The body shop is one of the vital production steps in automotive production. Banner offers sensors for reliable detection and error-proofing, as well as safety solutions that protect personnel and equipment. Adhesive Bead Detection Challenge During the assembly of car doors, adhesive is applied along the perimeter of the outer panel. The outer and inner panels are joined together by a press. If too little adhesive is applied, the panels will not adhere correctly. If too much adhesive is applied, it may burst...

Open the catalog to page 6

Paint Shop The automotive paint shop is a zero-fault-tolerance environment, and it requires solutions to have high availability, energy efficiency, and reliability even in harsh conditions. Banner sensors and systems are designed to perform reliably in this demanding environment. Light Tunnel for Paint Inspection Challenge In a recent automotive application, operators were complaining of eye strain when inspecting vehicles in the paint tunnel. Scratches and marks on the raw materials were missed during final inspection, causing delays in production. The warehouse manager wanted a light to...

Open the catalog to page 7

Powertrain Today, the automotive powertrain requires a high variety of models, in combination with shorter life cycles, cost-efficient manufacturing and optimized logistic processes. Banner sensors and solutions enable process optimization, save costs, and improve quality. Heavy-Duty Part Positioning Challenge In heavy-duty applications, sensors can be easily damaged during machine assembly, transport, maintenance, and operation. Solution • The right choice in harsh environmental conditions is the TM18 sensor. The nickel-plated, die-cast zinc, IP69K-rated design is the perfect solution for...

Open the catalog to page 8

EV Battery Production Electric vehicle manufacturing has unique challenges in QC and safety. The industry demands precision control of processes for producing lithium batteries, electric motors and charging systems. Banner offers trusted solutions, like battery-electrode-film thickness measurement and machine safeguarding for battery-pack assembly. Reliably Detect Adhesive Tape on Pouch Batteries Challenge Adhesive tape material is used to complete the outer film packaging, and the tape can be various colors depending on the production run. A standard contrast sensor can’t reliably detect...

Open the catalog to page 9

General Assembly Automotive assembly lines require a flexible JIT/JIS flow of material mixed with continuous quality checking and tracking. Proper station lighting, light guided assembly, and other error proofing is critical for success. Banner solutions enable customers to optimize processes and save costs. Control Cabinet Lighting Challenge Cabinets and enclosures require proper illumination for tasks such as component installation, maintenance, and monitoring. A maintenance technician needs a bright, ergonomic light source to wire relays and perform other tasks. Solution • The WLS15...

Open the catalog to page 10

Sensor Solutions Q4X Laser Distance Measurement Sensors Housing Style B = Bipolar discrete NPN & PNP K = Dual discrete with IO-Link U = 0–10 V analog I = 4–20 mA analog Q8 Q8 = Integral QD QD models require mating cordset *Not available with dual discrete with IO-Link output models Housing Style N = NPN P = PNP K = Dual discrete with IO-Link U = 0–10 V analog I = 4–20 mA analog Q8 = Integral QD QD models require mating cordset Q5X Laser Measurement Sensors Series K = Configurable dual discrete with L = Laser IO-Link on all models KU = 0–10 V with push/pull discrete output or IO-Link AF =...

Open the catalog to page 11All BANNER ENGINEERING CORP. catalogs and technical brochures

-

EG24 Sell Sheet

4 Pages

-

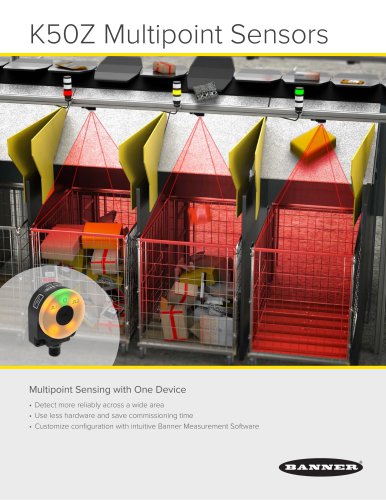

K50Z Sell Sheet

4 Pages

-

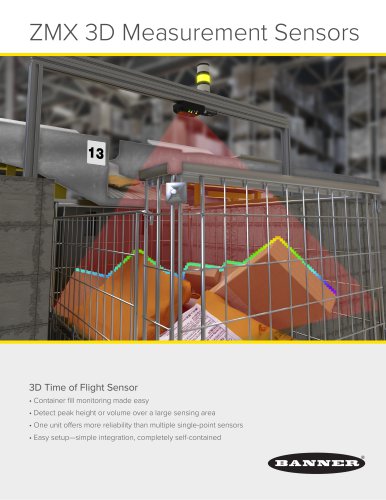

ZMX Sell Sheet

3 Pages

-

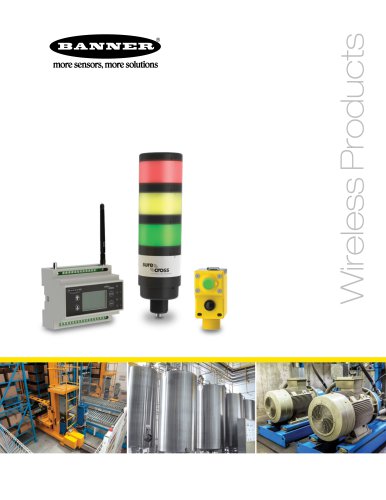

Wirreless Catalogue

92 Pages

-

Safety Solutions

33 Pages

-

New Product Catalog

39 Pages

-

Banner Overview Flyer

3 Pages

-

Banner New Product Flyer

4 Pages

-

AGV Solutions Brochure

3 Pages

-

Car Wash Solutions Brochure

5 Pages

-

Connectivity Solutions Brochure

28 Pages

-

IO-Link Solutions Brochure

20 Pages

-

Laser Sensor Solutions Brochure

11 Pages

-

Lighting and Indication Catalog

55 Pages

-

Monitoring Solutions Brochure

11 Pages

-

Packaging Solutions Brochure

80 Pages

-

Radar Sensor Solutions Brochure

13 Pages

-

Remote IO Brochure

9 Pages

-

Safety Solutions Catalog

33 Pages

-

Snap Signal Brochure

25 Pages

-

Vision Lighting Brochure

17 Pages

-

Leading Edge Brochure

16 Pages