Website:

Balluff GmbH

Website:

Balluff GmbH

Group: Balluff

Catalog excerpts

UP THE TEMPO WHILE IMPROVING QUALITY

Open the catalog to page 1

WE ARE AT HOME IN MANY INDUSTRY SECTORS

Open the catalog to page 2

CONTENTS Manage variety – get a grip on time 6 STORAGE AND RETRIEVAL Trendsetting in material flow 14 CONVEYING AND TRANSPORTING Correctly assembled – whether partially or fully automated 24 SORTING AND PICKING Step by step into the digital world 32 IIOT-CAPABLE WITH IO-LINK IIOT48 GLOBAL PROJECT MANAGEMENT 50

Open the catalog to page 3

MANAGE VARIETY – GET A GRIP ON TIME Controlling inventories and material movements at all times while reliably avoiding errors: This is the challenge facing companies in all industries. Automated processes enable you to store and retrieve even large inventory quantities in less time and with greater precision. So it's no wonder that dynamic shuttle systems and stacker cranes are increasingly replacing manual warehouse operations; They ensure efficient supply levels of the required goods, provide continuous operation and maintain high throughput. With accuracy and transparency – thanks to...

Open the catalog to page 4

Solutions for storage and retrieval High speeds and low error rates are the prerequisites for using warehouse space efficiently and providing materials flexibly, reliably and on time. You can achieve this through the addition of automation in your storage and retrieval operations – you just need the right sensor technology.

Open the catalog to page 5

DIGITIZING THE KANBAN SYSTEM BIS industrial RFID systems MEASURE FORK POSITION ON FORK LIFT TRUCKS BML magnetic encoder systems ROBOT POSITIONING IN PHARMACEUTICAL AUTOMATED VENDING MACHINES BML magnetic encoder systems CONTROL SHUTTLE SYSTEMS BOS photoelectric sensors MONITOR CARRIAGE POSITION BES inductive sensors MANAGE INVENTORIES DIGITALLY SRS Smart Reordering System Our solutions for e-Kanban systems automate the flow of materials and enable efficient, demand-oriented material supply on the production line. Using UHF RFID, the material management system communicates continuously with...

Open the catalog to page 6

RELIABLY CONTROL CRANE SYSTEMS BTL magnetostrictive linear position sensors KEEPING AN EYE ON INVENTORY BIS industrial RFID systems CONTROL MATERIAL FLOW AND TRACK TRAILERS BIS industrial RFID systems EFFICIENT SUPPORT FOR WORKERS BNI SmartLight stack lights and indicator lights To automate crane systems, continuous, accurate position monitoring is critical. Our long distance positioning system (LDPS) ensures this – even in harsh environments and over several hundred meters. It consists of a magnetostrictive linear position sensor with a Profinet interface and several position encoders that...

Open the catalog to page 7

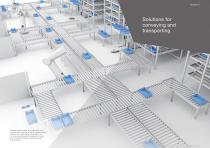

LEADING THE WAY IN MATERIAL FLOW Transporting, sorting, loading and unloading, buffering, accumulating – in all intralogistics tasks, throughput and availability at the right place at the right time are what counts in the end. Whether in cartons, totes, on pallets or hanging on trolleys, the goods must get from A to B as efficiently as possible. And it must do so with maximum flexibility, since batch sizes are becoming smaller and smaller as a result of progressive individualization. The linchpin of optimal transport solutions are automated conveyor systems. For these, Balluff supplies...

Open the catalog to page 8

Solutions for conveying and transporting Getting the right materials to the right place at the right time is the fundamental task for internal transport systems. With a high degree of automation, you can make material transport transparent, minimize errors and respond flexibly to higher speeds and lower quantities.

Open the catalog to page 9

CONTROL MATERIAL FLOW (GATE SOLUTION) BIS industrial RFID systems CONTROL MATERIAL FLOW (TUNNEL SOLUTION) BIS industrial RFID systems ENERGY-EFFICIENT MOVEMENT BNI network modules with IO-Link RELIABLY DETECT AND CHECK OBJECTS BOS photoelectric sensors UNIQUELY IDENTIFY BAGS BIS industrial RFID systems RELIABLE TRACKING OF UNITS BIS industrial RFID systems In warehouse areas with high through put, many material postings are made in order to always know exactly which stocks are leaving the warehouse and which items are arriving. Ideally, the identification is automated. Our stationary RFID...

Open the catalog to page 10

MONITOR AUTOMATED GUIDED VEHICLES BIS industrial RFID systems USE ALL RFID TECHNOLOGIES SIMULTANEOUSLY BIS industrial RFID systems PREVENT DOWNTIMES OF CONVEYOR MOTORS CMTK Condition Monitoring Tool Kit RELIABLY DETECT OBJECTS BES inductive sensors PALLET TRACKING BIS industrial RFID systems CHECK THE FILL LEVEL OF CONTAINERS BOS photoelectric sensors Rely on RFID from Balluff to reliably monitor automated guided vehicles (AGVs). Our RFID systems ensure, for example, that the AGV moves to the right box to deliver or pick up the correct load. For a smooth flow of goods, all information is...

Open the catalog to page 11

TRACE PARTS IN PRODUCTION AND ASSEMBLY BIS industrial RFID Systems WIRELESS DATA TRANSMISSION BNI IO-Link Wireless network modules NAVIGATE AUTOMATED GUIDED VEHICLES BIS industrial RFID systems CAPTURE DATA WHILE MOVING BIS industrial RFID systems Our high-speed RFID system makes the circulating stock of your automated assembly traceable. Its flexible BIS V processor unit, in combination with high-speed read/write heads, processes the read/write heads to process large volumes of data in the shortest possible time. The latter are up to 8 times faster than the global ISO 15693 standard,...

Open the catalog to page 12

CORRECTLY ASSEMBLED – WHETHER PARTIALLY OR FULLY AUTOMATED Whether for production or a customer order: Reliable sorting and picking are among the most complex and labor-intensive processes in intralogistics. To save costs, related tasks are continuously fully or partially automated. Our automation components and systems support you in the efficient implementation of such projects. The focus is on cost optimization in identification and quality control as well as in transport and labeling. This allows you to discover potential savings even where fully automated solutions are not possible,...

Open the catalog to page 13

Solutions for sorting and picking Sorting and picking tasks are very labor-intensive processes in intralogistics and thus tie up a lot of manpower. However, this labor is already in short supply today and is becoming increasingly expensive at the same time. The right sensor technology makes it possible to partially or fully automate entire processes and solve these problems.

Open the catalog to page 14All Balluff GmbH catalogs and technical brochures

-

PRODUCTS FOR EFFICIENT AUTOMATION 5

656 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 4

190 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 3

584 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 2

444 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 1

796 Pages

-

PRODUCTS + NEWS

25 Pages

-

GUIDED CHANGEOVER SOLUTION

3 Pages

-

PRODUCTS FOR THE WASHDOWN AREAS

88 Pages

-

MOBILE EQUIPMENT

21 Pages

-

SOLUTIONS FOR DRIVE TECHNOLOGY

15 Pages

-

TAILOR-MADE QUALITY

5 Pages

-

WE MONITOR YOUR MACHINES

10 Pages

-

PACKAGING, FOOD AND BEVERAGE

76 Pages

-

MANAGING ALL YOUR DATA

6 Pages

-

MAGNETIC FIELD SENSORS

7 Pages

-

Balluff products and services

94 Pages

Archived catalogs

-

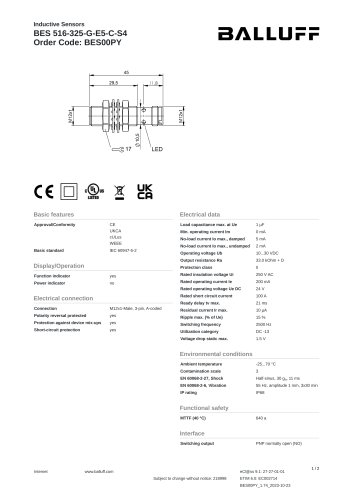

BES00PY

2 Pages

-

BES008L

2 Pages

-

BES02NC

2 Pages

-

BES01ZN

2 Pages

-

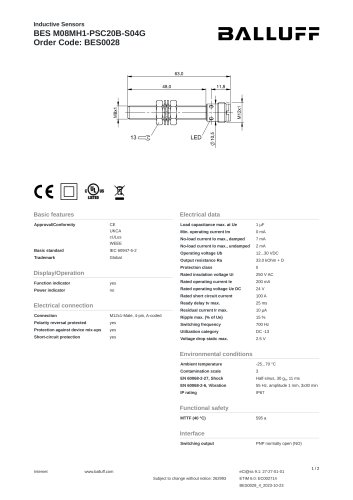

BES0028

2 Pages

-

BES05F9

2 Pages

-

BES054Z

2 Pages

-

BES0086

2 Pages

-

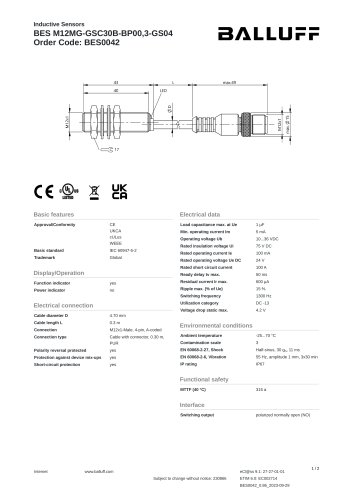

BES0042

2 Pages

-

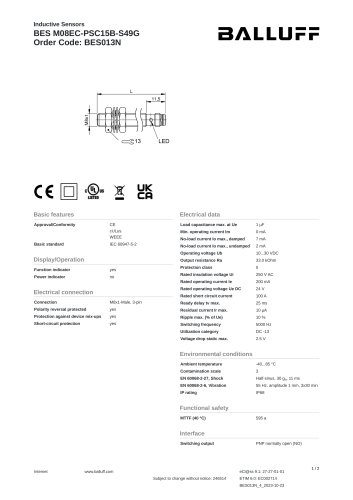

BES013N

2 Pages

-

BES00H4

2 Pages

-

BES003P

2 Pages

-

BES00HC

2 Pages

-

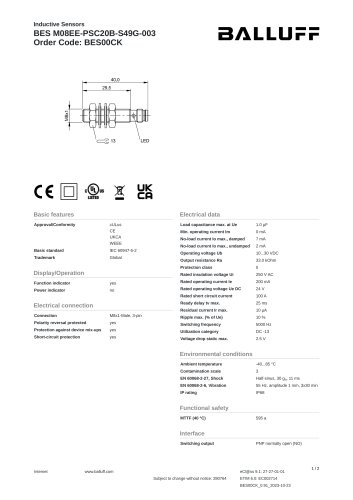

BES00CK

2 Pages

-

BES01ZW

2 Pages

-

BES00EF

2 Pages

-

BES00HF

2 Pages

-

BES00P7

2 Pages

-

BES0068

2 Pages

-

BES060T

2 Pages

-

QUALITY DOWN TO THE LAST DETAIL

94 Pages

-

OPENING NEW PERSPECTIVES

13 Pages

-

BALLUFF TEST CAMPUS

15 Pages