Website:

Balluff GmbH

Website:

Balluff GmbH

Group: Balluff

Catalog excerpts

Steel and Metallurgical Industry RELIABILITY AND FLEXIBILITY FROM A SINGLE SOURCE

Open the catalog to page 1

Steel and metallurgical industry | 3 Balluff in the steel and metallurgical industry WE ARE AT HOME IN MANY DIFFERENT SECTORS

Open the catalog to page 2

4 | Iron and Steel Industry Steel and metallurgical industry | 5 Balluff in the steel and metallurgical industry SINTER PLANT TECHNOLOGY EXPERTISE FOR THE ENTIRE VALUE CREATION CHAIN COKING PLANT BLAST FURNACE CONTINUOUS CASTING LINE HOT ROLLING AND HEAVY PLATE PRODUCTION COLD ROLLING AND SURFACE FINISHING Whether in the automobile industry, aviation and aerospace, energy production, construction or medical technology – steel plays a key role everywhere. It is extremely adaptable and meets the highest requirements. Its consistent quality when it comes to corrosion protection, low weight or...

Open the catalog to page 3

Steel and metallurgical industry | 7 CONTENTS Get off to the optimal start in steel production 8 COKING MACHINES, COKE OVEN BATTERIES AND CONVEYING EQUIPMENT Continuously manage magnetic fields and high temperatures 12 BLAST FURNACE AND ELECTRIC ARC FURNACE Maximum flexibility for various formats 18 CONTINUOUS CASTING LINE For a continuously reliable process 24 HOT ROLLING AND HEAVY PLATE PRODUCTION Maximum precision for the finish 30 COLD ROLLING AND SURFACE FINISHING

Open the catalog to page 4

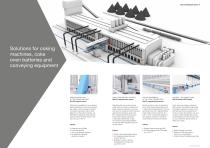

Steel and metallurgical industry | 9 Coking machines, coke oven batteries and conveying equipment GET OFF TO THE OPTIMAL START IN STEEL PRODUCTION No ifs or buts: the highest priority in a steel plant is an uninterrupted process. Meet these high requirements from the very start. Balluff provides you with highly reliable solutions for a wide variety of tasks pertaining to coking plant machines, the coke oven battery and conveying equipment. Just where things get really hot is where our rugged BTL magnetostrictive linear position sensor will get the job done at up to 100 ºC. It reliably...

Open the catalog to page 5

Steel and metallurgical industry | 11 Solutions for coking machines, coke oven batteries and conveying equipment POSITION DETECTION AT THE PUSHER MACHINE With BES inductive sensors COKE OVEN BATTERY CONTROL With BTL magnetostrictive sensors FOR ALL MOVEMENTS AT THE COKE OVEN BATTERY With BTL magnetostrictive sensors CONTROL THE PUSHER CARS With BIS industrial RFID systems Optimize the availability of your systems, reduce maintenance costs and increase the quality of your processes. Whether it's position sensing or end-of-travel detection on the pusher machine, our BES high-temperature rated...

Open the catalog to page 6

12 | Iron and Steel Industry Steel andIron and Steel Industry | 13 metallurgical industry Blast furnace and electric arc furnace CONTINUOUSLY MANAGE MAGNETIC FIELDS AND HIGH TEMPERATURES At no other place in the steel mill is process reliability as important as at the blast and arc furnaces. For once it is commissioned, a blast furnace is used around the clock over the course of years – hardly possible without continuous water cooling and replenishment. And just as critical to the process: absolutely reliable immunity to magnetic fields, safe inflow and outflow of gas when producing pig...

Open the catalog to page 7

14 | Steel and metallurgical industry Iron and Steel Industry | 15 Solutions for blast furnace and electric arc furnace Balluff solutions take over control functions at critical positions: our pressure sensors reliably measure water and air pressure. Magnetostrictive linear position sensors or inductive standard sensors monitor flap opening for controlling air intake and exhaust in the blast furnace. And in the electric arc furnace weld-spatter-resistant and magnetic field-immune inductive sensors check the precise position of the electrodes before they are properly gripped, assisted by...

Open the catalog to page 8

Steel and metallurgical industry | 17 ELECTRODE MONITORING IN THE ELECTRIC ARC FURNACE With BKT contrast sensors ASSURING THE CORRECT ELECTRODE POSITION With BES inductive sensors MEASURING THE INCLINATION OF THE CASTING LADLE With BSI inclination sensors PRESSURE MEASUREMENT FOR WATER COOLING With BSP pressure sensors RELIABLY REGULATING AIR AND GAS SUPPLY AT THE BLAST FURNACE With BTL magnetostrictive sensors LEVEL MONITORING OF CHARGES AND COKE With BUS ultrasonic sensors Sensors for detecting color and contrast support the positioning of electrodes in the arc furnace. The sensor, which...

Open the catalog to page 9

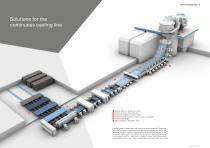

18 | Iron and Steel Industry Steel andIron and Steel Industry | 19 metallurgical industry Continuous casting line MAXIMUM FLEXIBILITY FOR VARIOUS FORMATS As efficiency increases, so do the demands on continuous casting lines. Large forces, vibrations and shock have to be controlled in the continuous casting line: at the ingot mold movement for the homogeneity of the fluid metal or at the walking-beam for transport of slabs or billets. Comprehensive monitoring measures are, therefore, indispensable. But the investment pays off, because only in this way can you prevent costly pouring...

Open the catalog to page 10

Steel and metallurgical industry | 21 Solutions for the continuous casting line 1 Highest safety for casting ladle control Position sensing at the dummy bar Fast sensor replacement without leaks Additional sensor protection when the system is stopped Checking slab length Slabs transport on the walking beam The steel quality is determined at the continuous casting segments. The desired properties are achieved depending on the gradient, temperature and time of the reshaping. Therefore, maximum flexibility and peak reliability are required for the technology. Balluff sensors and systems...

Open the catalog to page 11

Steel and metallurgical industry | 23 HIGHEST SAFETY FOR CASTING LADLE CONTROL With BTL magnetostrictive sensors POSITION SENSING AT THE DUMMY BAR With BMF magnetic field sensors FAST SENSOR REPLACEMENT WITHOUT LEAKS With BTL magnetostrictive sensors ADDITIONAL SENSOR PROTECTION WHEN THE SYSTEM IS STOPPED With BOS photoelectric sensors CHECKING SLAB LENGTH With BOD photoelectric distance sensors SLAB TRANSPORT ON THE WALKING BEAM With BSI inclination sensors The casting ladle movement requires peak reliability. And for safety reasons, all of this argues for multiple redundancy of the...

Open the catalog to page 12All Balluff GmbH catalogs and technical brochures

-

PRODUCTS FOR EFFICIENT AUTOMATION 5

656 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 4

190 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 3

584 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 2

444 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 1

796 Pages

-

PRODUCTS + NEWS

25 Pages

-

GUIDED CHANGEOVER SOLUTION

3 Pages

-

PRODUCTS FOR THE WASHDOWN AREAS

88 Pages

-

MOBILE EQUIPMENT

21 Pages

-

SOLUTIONS FOR DRIVE TECHNOLOGY

15 Pages

-

TAILOR-MADE QUALITY

5 Pages

-

WE MONITOR YOUR MACHINES

10 Pages

-

PACKAGING, FOOD AND BEVERAGE

76 Pages

-

MANAGING ALL YOUR DATA

6 Pages

-

MAGNETIC FIELD SENSORS

7 Pages

-

Balluff products and services

94 Pages

Archived catalogs

-

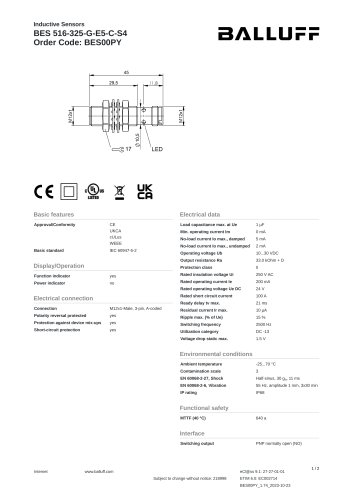

BES00PY

2 Pages

-

BES008L

2 Pages

-

BES02NC

2 Pages

-

BES01ZN

2 Pages

-

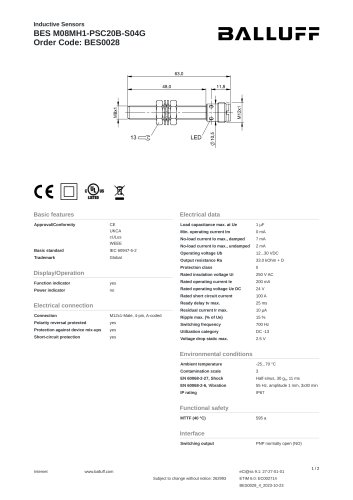

BES0028

2 Pages

-

BES05F9

2 Pages

-

BES054Z

2 Pages

-

BES0086

2 Pages

-

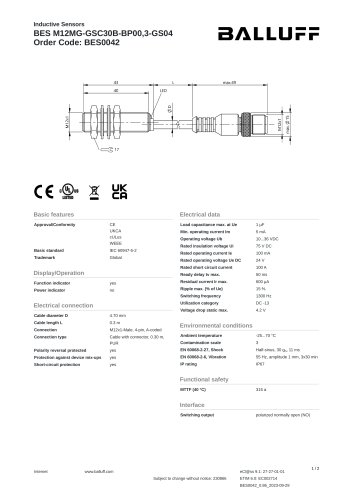

BES0042

2 Pages

-

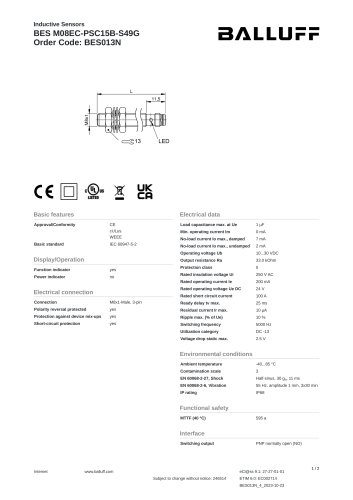

BES013N

2 Pages

-

BES00H4

2 Pages

-

BES003P

2 Pages

-

BES00HC

2 Pages

-

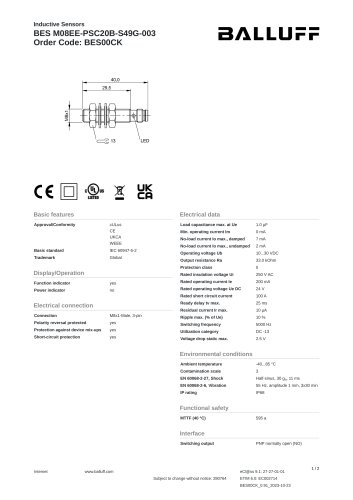

BES00CK

2 Pages

-

BES01ZW

2 Pages

-

BES00EF

2 Pages

-

BES00HF

2 Pages

-

BES00P7

2 Pages

-

BES0068

2 Pages

-

BES060T

2 Pages

-

QUALITY DOWN TO THE LAST DETAIL

94 Pages

-

OPENING NEW PERSPECTIVES

13 Pages

-

BALLUFF TEST CAMPUS

15 Pages