Website:

Balluff GmbH

Website:

Balluff GmbH

Group: Balluff

Catalog excerpts

Battery industry QUALITY AND RELIABILITY FOR THE MOBILITY OF THE FUTURE

Open the catalog to page 1

Balluff in battery production WE MOVE THE AUTOMOTIVE INDUSTRY FORWARD

Open the catalog to page 2

Balluff in the battery industry SOLUTIONS FOR AUTOMATED BATTERY PRODUCTION The mobility revolution is in full swing and the battery plays a fundamental role in this transformation, whether for a pure electric, hybrid or fuel cell vehicle. Throughout the production of individual battery cells, modules and packs, machine and plant automation is important for scalable, efficient and reliable manufacturing. Therefore Balluff supports you in automating your battery production processes from electrode manufacturing to battery pack assembly. We‘re your single source partner: Our portfolio includes...

Open the catalog to page 3

CONTENT Quality assurance from the start 8 ELECTRODE PRODUCTION AND CELL ASSEMBLY Traceability and flexibility in all steps 16 MODULE AND PACK ASSEMBLY Precision and communication 20 OUR STRENGTHS: IO-LINK AND RFID

Open the catalog to page 4

Electrode production and cell assembly QUALITY ASSURANCE FROM THE START In addition to the mixing of slurry, electrode production and cell assembly also include coating, drying, calendering, stacking, winding, welding and electrolyte filling. In all such production steps, different parameters and quality charactaristics must reliably be maintained. These include, for example, a certain coating thickness, electrode cleanliness and the correct positioning during stacking. We support you in meeting these high requirements with a broad range of optical sensors in roll-to-roll processes....

Open the catalog to page 5

Solutions for electrode production and cell assembly ➔ IDENTIFY RAW MATERIALS FOR SLURRY PRODUCTION BVS handheld code reader and BIS industrial RFID systems To produce the electrode paste for the anode and cathode at the start of battery cell production, the raw materials must first be clearly identified. The required active materials, conductive carbon blacks, solvents or binders, and additives are often marked with barcodes. At Balluff, you can find various products for reading these codes, as well as alternative identification solutions. These include handheld readers and RFID systems...

Open the catalog to page 6

MONITOR MATERIAL AVAILABILITY BOD optoelectronic distance sensors FOIL WEB EDGE DETECTION BGL fork sensors CONTINUOUSLY TRACK ROLLS BSI inclination sensors To ensure that there is always enough material available for the coating process, our optical distance sensors monitor how much carrier film is still on the roll. This allows you to replace coils at an early stage and avoid having to interrupt the coating process. Thanks to their IO-Link interface, the sensors are also very easy to commission and can be flexibly adapted for your application. If aluminum and copper foils for different...

Open the catalog to page 7

ENSURE PROCESS RELIABILITY BLA light bands CONTROL CALENDER ROLLS BTL position measuring systems When conveying coated carrier films, it is important to maintain an optimum distance between the rolls. Otherwise, the process could be blocked and, in the worst case, the machine could come to a standstill. Our compact light band reliably monitors the distance between rolls during calendering to prevent this. Its IO-Link interface also enables central data storage and simple configuration – even in the event of format changes. To compact the copper or aluminum foils coated on both sides, the...

Open the catalog to page 8

Module and pack assembly TRACEABILITY AND FLEXIBILITY IN ALL STEPS After the final process steps of cell production have been completed, the battery cells are assembled into modules and finally battery packs. This is done in highly automated production lines. With our vision offer you monitor all steps in the assembly process. Code reading, for example, ensures that the right cells are assembled. Our IO-Link portfolio enables automated, connected and modular assembly architectures. At the same time, our RFID products provide seamless identification of your modules and packs.

Open the catalog to page 9

Solutions for battery assembly ➔ ➔ ➔ ➔ RELIABLY IDENTIFY BATTERY CELLS BVS vision sensor ident DETECT CELL PRESENCE DURING BATTERY ASSEMBLY BOS diffuse sensor FLEXIBLE AND WEAR-FREE ENERGY TRANSMISSION BIC inductive couplers CHECK THE QUALITY OF THE FINISHED BATTERY MODULE BVS industrial camera IDENTIFY AND TRACK BATTERY MODULES BIS industrial RFID Systems Our Vision sensor ident also helps you to avoid quality defects during the further processing of battery cells into modules or packs. It reliably detects bar codes, data matrix codes and even QR codes, thus ensuring that the correct cells...

Open the catalog to page 10

As an automation specialist, we have already launched numerous innovations. Nevertheless, we do not stand still: We want to actively shape the future of digitalization and the Industrial Internet of Things. That‘s why we deliver precise, intelligent and networked solutions that make you and your production fit for the future. We are the right partner for the automotive industry and for automotive suppliers to sustainably meet the challenges around flexibility, plant availability, quality, and data management in the industry. We offer you future-proof concepts for your modern battery...

Open the catalog to page 11

Modular control concepts From parallel wiring to fieldbus protocol WHY IO-LINK ON THE FAST LANE IS Replacing parallel wiring with fieldbus use was a huge step. Because the fieldbus protocol successfully overcame the immense installation effort with expensive copper cables. And significantly reduced costs.But fieldbus protocols are not without their pitfalls. With IO-Link, however, flexibility goes much further. Because with Safety over IO-Link, Balluff offers you the first safety solution that can be integrated with IO-Link, which combines safety and automation technology in one system....

Open the catalog to page 12

More efficiency, less costs IO-LINK SAVES TIME AND MONEY FIELDBUS MASTER WITH IO-LINK INTERFACE Easy installation Demand oriented maintenance In addition to the IO-Link master, all you need to install the universal interface is an industry-standard three- or fourconductor core cable. You can quickly integrate the intelligent communication standard into the fieldbus world and easily integrate even complex devices. A particularly interesting feature is that digital communication guarantees interference immunity even without expensive shielded cabling. Analog signals are digitized without...

Open the catalog to page 13All Balluff GmbH catalogs and technical brochures

-

PRODUCTS FOR EFFICIENT AUTOMATION 5

656 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 4

190 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 3

584 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 2

444 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 1

796 Pages

-

PRODUCTS + NEWS

25 Pages

-

GUIDED CHANGEOVER SOLUTION

3 Pages

-

PRODUCTS FOR THE WASHDOWN AREAS

88 Pages

-

MOBILE EQUIPMENT

21 Pages

-

SOLUTIONS FOR DRIVE TECHNOLOGY

15 Pages

-

TAILOR-MADE QUALITY

5 Pages

-

WE MONITOR YOUR MACHINES

10 Pages

-

PACKAGING, FOOD AND BEVERAGE

76 Pages

-

MANAGING ALL YOUR DATA

6 Pages

-

MAGNETIC FIELD SENSORS

7 Pages

-

Balluff products and services

94 Pages

Archived catalogs

-

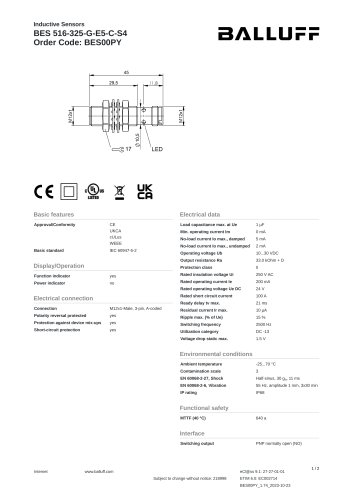

BES00PY

2 Pages

-

BES008L

2 Pages

-

BES02NC

2 Pages

-

BES01ZN

2 Pages

-

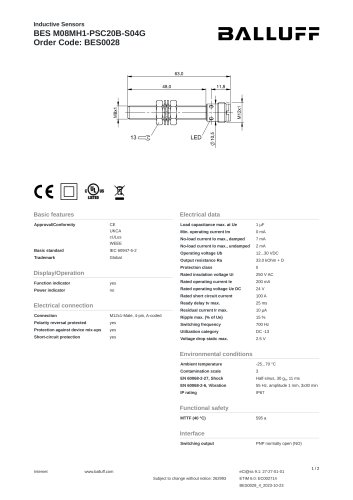

BES0028

2 Pages

-

BES05F9

2 Pages

-

BES054Z

2 Pages

-

BES0086

2 Pages

-

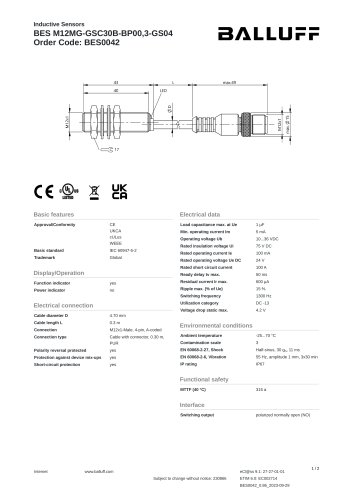

BES0042

2 Pages

-

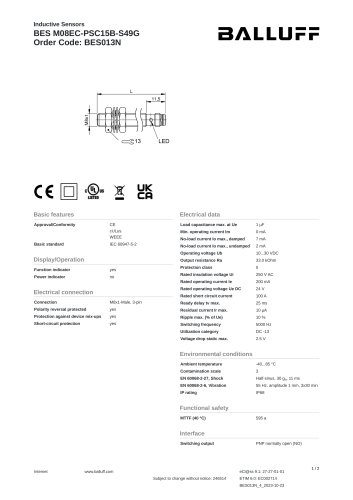

BES013N

2 Pages

-

BES00H4

2 Pages

-

BES003P

2 Pages

-

BES00HC

2 Pages

-

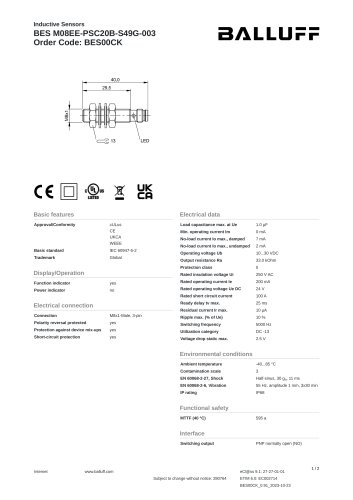

BES00CK

2 Pages

-

BES01ZW

2 Pages

-

BES00EF

2 Pages

-

BES00HF

2 Pages

-

BES00P7

2 Pages

-

BES0068

2 Pages

-

BES060T

2 Pages

-

QUALITY DOWN TO THE LAST DETAIL

94 Pages

-

OPENING NEW PERSPECTIVES

13 Pages

-

BALLUFF TEST CAMPUS

15 Pages