Website:

Balluff GmbH

Website:

Balluff GmbH

Group: Balluff

Catalog excerpts

Plastics Industry PRECISION FOR HIGH EQUIPMENT AVAILABILITY

Open the catalog to page 1

Plastics Industry WE ARE AT HOME IN MANY DIFFERENT SECTORS

Open the catalog to page 2

How to achieve an optimal process 6 MATERIAL HANDLING In control of every detail 10 INJECTION MOLDING Economy through optimal material utilization 16 BLOW MOLDING A continuous eye on every seam 20 BONDING AND JOINING TECHNOLOGY Reduce costs with a lean network 24 AUTOMATION AND ROBOTICS Connected Mold-ID – Automated tool data management

Open the catalog to page 3

Material handling HOW TO ACHIEVE AN OPTIMAL PROCESS To maintain an optimal material handling process it is important to continuously ensure the cleanliness of the plastic. Proper fill levels are ensured by our capacitive and ultrasonic sensors while industrial RFID handles unerring control of all the processes. This ensures that the paths taken by the granulate, fillers and reinforcing materials from the silos to the coupling stations, from the mixers to the injection molding machines run like clockwork. In different production lines and in every single batch. You achieve precise metering...

Open the catalog to page 4

Solutions for material handling KEEP A CONTINUOUS EYE ON LEVELS BUS ultrasonic sensors Our high-resolution ultrasonic sensors don't miss a thing: they reliably monitor the level of granulates and powders in silos. The continuous and contact-free measurement technology is virtually immune to dust and dirt. The fill level can be output as needed by an analog signal or with two switching signals as min./max. values. LEVEL FEEDBACK FOR CONSTANT MATERIAL FEED BCS capacitive sensors FAST, RELIABLE CONTROL IN THE COUPLING STATION BIS industrial RFID systems CONSISTENTLY EVEN GRANULATE FEED BCS...

Open the catalog to page 5

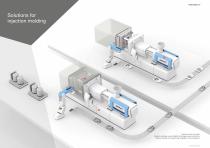

Injection molding IN CONTROL OF EVERY DETAIL In high-precision injection molding every step has to be performed precisely from injecting the molding compound to ejecting the formed part. With our high-quality solutions you can reliably control every movement of the injection molding machine. Our inductive positioning systems provide rapid mold filling and our capacitive sensors check for completeness. Magnetic encoders ensure soft mold closing. Rugged pressure sensors integrated into the hydraulic cylinder ensure that the platens are properly closed. You can rely on high repeat accuracy and...

Open the catalog to page 6

Solutions for injection molding 3 Precision stands for quality: Resilient, extremely accurate Balluff technology ensures continuity in injection molding and supports high availability of your equipment.

Open the catalog to page 7

ENSURE GENTLE MOLD CLOSING BTL magnetostrictive linear position sensors With the help of a high-precision magnetostrictive linear position sensor from Balluff you can precisely monitor the closing motion of the platen. A gentle mold closure reduces wear and extends your mold's useful life. DETECT INJECTION MOVEMENT ON MOLDS BIW inductive linear positioning systems CONTINUOUSLY MONITOR TIE BAR EXTENSION BAW inductive distance sensors Our inductive positioning systems ensure that your molds are quickly filled. The high sampling frequency and repeat accuracy measure the travel of the injection...

Open the catalog to page 8

Blow molding ECONOMY THROUGH OPTIMAL MATERIAL UTILIZATION When it comes to blow molding, Balluff offers you great precision for optimal material utilization. Our products ensure exact extrusion of the hoses and allow for the correct structure of multiple plastic layers. And we make it possible to reliably produce containers with acid-resistant inner walls, different wall thicknesses or in various colors. Our sensors provide an economical solution that guarantees the desired product quality because only exact processing of the individual materials lets you be sure that, for example, tanks...

Open the catalog to page 9

Solutions for blow molding A BLOCK FOR GREATER TRANSPARENCY BNI IO-Link block KEEP A FIRM GRASP ON ALL MOVEMENTS BTL magnetostrictive linear position sensors RAPID TOOL CHANGES AND SECURE PROTECTION FROM COUNTERFEITING BIS industrial RFID systems The EtherCAT block from Balluff with IO-Link interface bundles the signals from a variety of standard sensors and passes them along to the controller. This solution simplifies the entire network structure and creates transparency down to the last meter. Travel movements at the blow station are under control with Balluff BTL magnetostrictive linear...

Open the catalog to page 10

Bonding and joining technology A CONTINUOUS EYE ON EVERY SEAM When it comes to secure joining parts, whether of the same and different materials, both ultrasonic and vibration welding offer the best features. By using these welding techniques you ensure the best possible mechanical strength and sealing of the joined materials. To reliably inspect these first-class joining technologies we offer proven solutions. This applies as well to sensitive areas such as the foods industry or medical and electronics. You can continuously compare the results during the process. Super-fast linear...

Open the catalog to page 11

Solutions for bonding and joining technology RELIABLE ALIGNMENT OF THE WELDING HEAD BMP magnetic field positioning system Our magnetic field positioning systems provide reliable position feedback. They check the welding head position without contact and fit in the tightest of spaces while improving process reliability and automation quality. Thanks to the modular design you can use them with a variety of cylinders up to 256 mm to cover the entire stroke. VISUAL QUALITY CONTROL BVS SmartCameras The SmartCamera checks all the parts including their production stages: are they complete and...

Open the catalog to page 12

Plastics Industry | 25 Plastics and Systems | 25 LEAN NETWORKS REDUCE COSTS Robotic automation tasks are no longer necessarily associated with excessive installation costs and effort, maintenance, and parts replacement. With non-contact transmission of signals and power using inductive couplers, you can leave wear and cable breaks in the past. Use of these quick-disconnect units also makes you highly flexible. By also using IO-Link you can significantly simplify your network topology. You reduce the installation costs and effort to a minimum while enjoying noise immunity. With this...

Open the catalog to page 13All Balluff GmbH catalogs and technical brochures

-

PRODUCTS FOR EFFICIENT AUTOMATION 5

656 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 4

190 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 3

584 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 2

444 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 1

796 Pages

-

PRODUCTS + NEWS

25 Pages

-

GUIDED CHANGEOVER SOLUTION

3 Pages

-

PRODUCTS FOR THE WASHDOWN AREAS

88 Pages

-

MOBILE EQUIPMENT

21 Pages

-

SOLUTIONS FOR DRIVE TECHNOLOGY

15 Pages

-

TAILOR-MADE QUALITY

5 Pages

-

WE MONITOR YOUR MACHINES

10 Pages

-

PACKAGING, FOOD AND BEVERAGE

76 Pages

-

MANAGING ALL YOUR DATA

6 Pages

-

MAGNETIC FIELD SENSORS

7 Pages

-

Balluff products and services

94 Pages

Archived catalogs

-

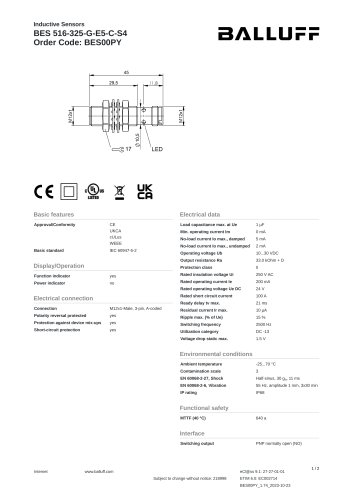

BES00PY

2 Pages

-

BES008L

2 Pages

-

BES02NC

2 Pages

-

BES01ZN

2 Pages

-

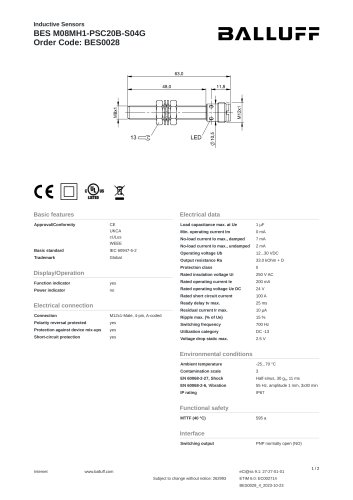

BES0028

2 Pages

-

BES05F9

2 Pages

-

BES054Z

2 Pages

-

BES0086

2 Pages

-

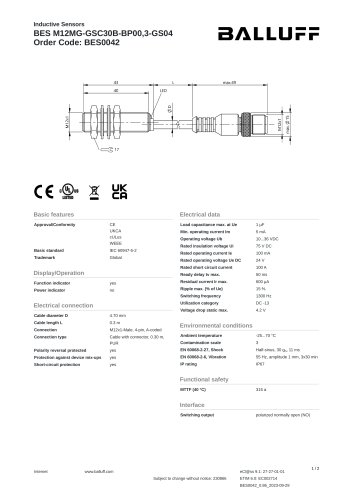

BES0042

2 Pages

-

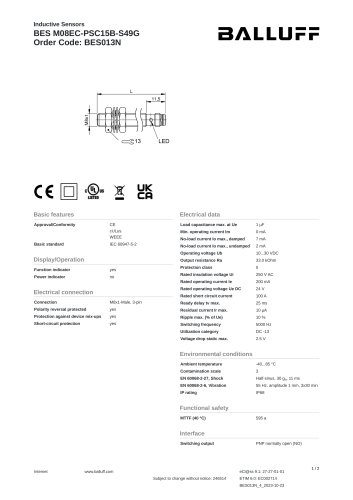

BES013N

2 Pages

-

BES00H4

2 Pages

-

BES003P

2 Pages

-

BES00HC

2 Pages

-

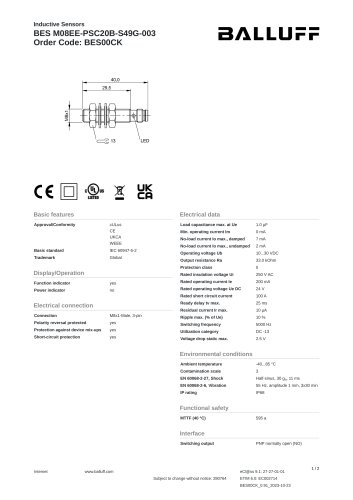

BES00CK

2 Pages

-

BES01ZW

2 Pages

-

BES00EF

2 Pages

-

BES00HF

2 Pages

-

BES00P7

2 Pages

-

BES0068

2 Pages

-

BES060T

2 Pages

-

QUALITY DOWN TO THE LAST DETAIL

94 Pages

-

OPENING NEW PERSPECTIVES

13 Pages

-

BALLUFF TEST CAMPUS

15 Pages