Website:

Balluff GmbH

Website:

Balluff GmbH

Group: Balluff

Catalog excerpts

Automating Your Machinery FOR PACKAGING, FOODS, BEVERAGES, PHARMACEUTICALS AND COSMETICS

Open the catalog to page 1

Automation technology WE ARE AT HOME IN MANY DIFFERENT SECTORS

Open the catalog to page 2

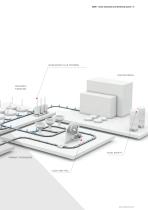

Transparency brings optimal performance. 6 SAMS – SIMPLE, FLEXIBLE, INTELLIGENT Perfectly prepared. Hygienic and high quality. 12 FOOD INDUSTRY At rapid pace. Smooth flowing and reliable. 22 BEVERAGE INDUSTRY Flexibly deployed. Precisely metered. 28 PHARMACEUTICALS AND COSMETICS INDUSTRIES Prepared for anything. Tailor-made and efficient. PRODUCT OVERVIEW 48 APPLICATIONS 54 CUSTOM TAILORED TOTAL PACKAGES 56 USE CASE 58 ABOUT BALLUFF 60 REFERENCES 62

Open the catalog to page 5

SAMS – Smart Automation and Monitoring System | 7 SAMS – simple, flexible, intelligent TRANSPARENCY BRINGS OPTIMAL PERFORMANCE Increasing the efficiency of machines and equipment requires high-performance, multi-functional solutions that provide not only machine control but also data about machine condition. This information lets you optimize the performance of every machine and, thereby, optimize the entire plant, so that you can design processes and sequences efficiently and flexibly. This information also enables full transparency. Changing requirements in filling and packaging can now...

Open the catalog to page 7

Optimal Performance SMART FEATURES SECONDARY AND FINAL PACKAGING

Open the catalog to page 8

SAMS – Smart Automation and Monitoring System | 9 WASHDOWN PLUS PROMISE PROCESS/ FINISHING FOOD SAFETY PRIMARY PACKAGING

Open the catalog to page 9

THE WASH DOWN PLUS PROMISE FOOD SAFETY All the washdown components that are part of the Smart Automation and Monitoring System (SAMS) are designed so that they can withstand the tough demands of cleaning processes. At home in extremely harsh environments, they meet Ecolab requirements. They are perfectly protected from cleaning agents and water, and with a rating of at least 1000 cleaning cycles our products far exceed the requirements for IP69K. The result: significantly longer service life, less maintenance effort and expense, and overall significant cost savings. SAMS also offers you...

Open the catalog to page 10

SAMS – Smart Automation and Monitoring System | 11 SMART FEATURES Once placed in service, the devices are turned into data sources which you can use for reliable operation of your equipment. For example, you can gain temperature monitoring, relative humidity measurement, inclination detection, vibration monitoring, signal quality display, operating hours counters or time functions. Such features eliminate the need for additional devices with a monitoring function, significantly reducing your inventory levels. In addition, each component can be uniquely located within the system by pinging....

Open the catalog to page 11

Food industry PERFECTLY PREPARED. HYGIENIC AND HIGH QUALITY The components in our SAMS are, thanks to Washdown-Plus, designed for more than 1000 cleaning cycles and, thereby, exceed the requirements of IP69K. This provides for long service life and less maintenance effort. DAIRY The dairy industry is subject to the strictest hygienic and quality regulations. This is why a real-time capable and transparent production process with modular production lines is indispensable for efficient production. Only in this way, can traceability and flexibility be ensured. Our comprehensive product...

Open the catalog to page 12

Vehicle detection Monitoring the hydraulics in homogenizing equipment Controlling product flow at the coupling panels Level detection in a yogurt tank Checking for container presence Object detection during production Colored label detection

Open the catalog to page 14

VEHICLE IDENTIFICATION BIS Industrial RFID Systems MONITORING THE HYDRAULICS IN HOMOGENIZING EQUIPMENT BSP Pressure Sensors The milk transport vehicles are equipped Homogenization as a standard industrial with RFID tags. Now every transport process enables stabilizing of fat step can be tracked: from the laboratory emulsions to prevent gravity induced test to quality inspection, to the pumps separation. The hydraulic circuit within moving milk from the vehicle tank to the homogenizer must be continuously the storage containers, to cleaning of monitored. In addition to pressure and the...

Open the catalog to page 15

CONTROLLING PRODUCT FLOW AT THE COUPLING PANEL BES Inductive Sensors LEVEL DETECTION IN A YOGURT TANK BCS Capacitive Sensors CHECKING THE PRESENCE OF THE CONTAINER FOR SECURE FILLING BUS Ultrasonic Sensors Coupling panels are used for manual changes between different piping paths. The coupling elbows are used to connect the pipes in various combinations. Elbow position is detected by a BES inductive sensor, whose housing is resistant to abrasive and aggressive media. The LEDs are protected from mechanical damage as well, and the housing construction is optimized for frequent cleaning. Level...

Open the catalog to page 16

OBJECT DETECTION DURING PRODUCTION BOS Photoelectric Sensors COLORED LABEL DETECTION BFS Photoelectric Color Sensors Hygienic regulations are especially critical in the production of milk products. Optical sensors for object detection from Balluff meet the relevant hygiene requirements. These rugged sensors can be cleaned in-process using any of the common procedures. Aggressive media such as cleaning agents have no effect on them. When detecting label colors, even the slightest shade differences need to be recognized. This means the sensors have to reliably detect faded colors or...

Open the catalog to page 17

Solutions for meat processing Detecting the PEF417 code on the delivered raw material Level sensing in the mixer/mincer Position detection in the hygienic area Detecting hooks in conveyor systems Monitoring safety on automatic saws in the cutting process 6 Optical detection on automatic saws in the cutting process 7 Transporting signals reliably and error-free

Open the catalog to page 18

SCANNING THE PDF417 CODE OF THE DELIVERED RAW MATERIALS BVS Optical Identification LEVEL SENSING IN THE MIXER/MINCER BCS Capacitive Sensors POSITION DETECTION IN THE HYGIENIC AREA BOS Photoelectric Sensors When the raw product is delivered it must first be detected and identified. This is done using so-called PDF417 codes located on the raw product. Unfortunately, these codes are frequently not at the same height. By using the portable reader BVS HS-P the codes can still be read simply and flexibly. Continuous and errorless processing requires that there always be sufficient meat in the...

Open the catalog to page 19All Balluff GmbH catalogs and technical brochures

-

PRODUCTS FOR EFFICIENT AUTOMATION 5

656 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 4

190 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 3

584 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 2

444 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 1

796 Pages

-

PRODUCTS + NEWS

25 Pages

-

BALLUFF TEST CAMPUS

15 Pages

-

GUIDED CHANGEOVER SOLUTION

3 Pages

-

PRODUCTS FOR THE WASHDOWN AREAS

88 Pages

-

MOBILE EQUIPMENT

21 Pages

-

SOLUTIONS FOR DRIVE TECHNOLOGY

15 Pages

-

TAILOR-MADE QUALITY

5 Pages

-

WE MONITOR YOUR MACHINES

10 Pages

-

PACKAGING, FOOD AND BEVERAGE

76 Pages

-

MANAGING ALL YOUR DATA

6 Pages

-

MAGNETIC FIELD SENSORS

7 Pages

-

Balluff products and services

94 Pages

Archived catalogs

-

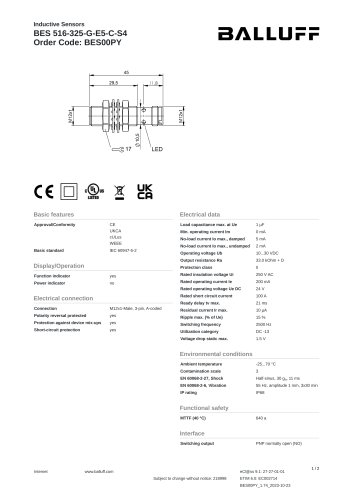

BES00PY

2 Pages

-

BES008L

2 Pages

-

BES02NC

2 Pages

-

BES01ZN

2 Pages

-

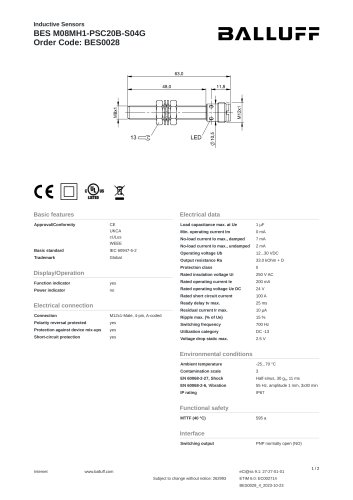

BES0028

2 Pages

-

BES05F9

2 Pages

-

BES054Z

2 Pages

-

BES0086

2 Pages

-

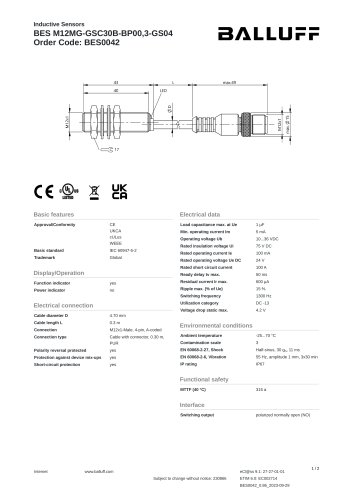

BES0042

2 Pages

-

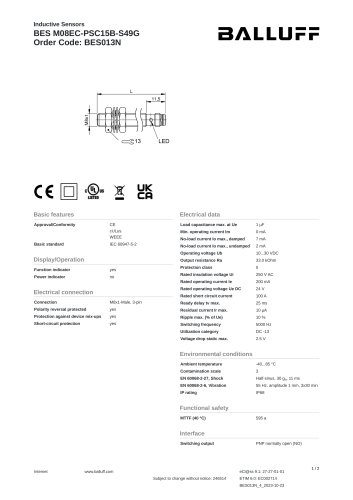

BES013N

2 Pages

-

BES00H4

2 Pages

-

BES003P

2 Pages

-

BES00HC

2 Pages

-

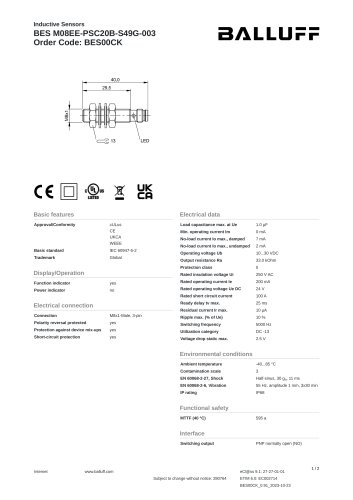

BES00CK

2 Pages

-

BES01ZW

2 Pages

-

BES00EF

2 Pages

-

BES00HF

2 Pages

-

BES00P7

2 Pages

-

BES0068

2 Pages

-

BES060T

2 Pages

-

QUALITY DOWN TO THE LAST DETAIL

94 Pages

-

OPENING NEW PERSPECTIVES

13 Pages