Website:

Balluff GmbH

Website:

Balluff GmbH

Group: Balluff

Catalog excerpts

Reliability and efficiency guaranteed MOBILE EQUIPMENT

Open the catalog to page 1

Mobile Equipment WE ARE AT HOME IN MANY DIFFERENT SECTORS

Open the catalog to page 2

CONTENTS Agriculture and Forestry Vehicles 6 SOLUTIONS FOR EFFICIENT OPERATION Construction Machinery and Mining Vehicles 12 MAXIMUM SUPPORT FOR THE OPERATOR Logistics and Material Handling Vehicles 18 SENSORS FOR INTELLIGENT AUTOMATION Special Purpose Vehicles 24 ENSURING TROUBLE-FREE OPERATION

Open the catalog to page 3

Solutions for efficient operation AGRICULTURE AND FORESTRY VEHICLES Global population growth represents new challenges for agriculture and forestry. The increased need for food and raw materials raises the demands on crop yields and the efficiency of equipment. The buzzwords for new machine concepts are precision farming, self-driving vehicles, and smart solutions based on existing automation technologies. In addition to attractive basic components, we provide you with automation solutions for more efficient operation of your machines.

Open the catalog to page 4

Solutions for agriculture and forestry 4 1 Combine harvester: Measuring the height of the head 2 Field sprayer: Measuring the tank level 3 Timber harvester with crane: Monitoring park position of the chainsaw 4 Apple picking platform: Monitoring the platform position

Open the catalog to page 5

COMBINE HARVESTER: MEASURING THE HEIGHT OF THE HEAD With BUS ultrasonic sensors To avoid waste, the head on a combine must always remain parallel to the ground and maintain a defined distance from it. Our ultrasonic sensors measure the distance of the head from the ground at no fewer than two locations (right, left) and levels the distance using two hydraulic cylinders. It ensures consistent harvest and maximum yield, even on uneven terrain and slopes. 4 FIELD SPRAYER: MEASURING THE TANK LEVEL With flexible, self-adhesive capacitive BCW sensor head TIMBER HARVESTER WITH CRANE: MONITORING...

Open the catalog to page 6

Maximum support for the operator CONSTRUCTION MACHINERY AND MINING VEHICLES Urbanization is ensuring a booming construction industry. Investment is being made in construction and civil engineering, and the manufacture of construction equipment is continually increasing. As a result of the great pressure placed on construction to be ever faster and more efficient, topics such as digitalization of the machine and partial self-driving capabilities to assist the operator are gaining in significance. This creates a great need for innovative automation concepts for which we at Balluff offer...

Open the catalog to page 7

Solutions for construction machinery and mining vehicles 1 Excavators: Detecting excavator attachments Mobile crane: Detecting the position of the mobile crane over 360° Mobile crane: Monitoring the end position of the outriggers Universal drilling rig: Monitoring the position of the hydraulic cylinder

Open the catalog to page 8

EXCAVATOR: DETECTING EXCAVATOR ATTACHMENTS With BIS RFID systems MOBILE CRANE: DETECTING THE POSITION OF THE MOBILE CRANE OVER 360° With BML magnetic encoder systems MOBILE CRANE: MONITORING THE END POSITION OF THE OUTRIGGERS With BES inductive sensors To use an excavator efficiently, you need the right tool. RFID systems from Balluff are ideal for reliably identifying excavator attachments such as buckets, vibrators and drills. Since these tools are uniquely identified with a data carrier, the read/ write head on the excavator arm can reliably detect them. From the cab the driver only...

Open the catalog to page 9

Sensors for Intelligent Automation LOGISTICS AND MATERIAL HANDLING VEHICLES The logistics industry has been for some years in a distinct upward curve. On one hand, the growing online shopping business means that warehouse processes need to be automated, since manual work is too susceptible to error. Automation, including driverless logistics vehicles, can increase the work schedule to 24/7. On the other hand, the industry is developing new assembly concepts which rely increasingly on individual process steps being linked together through automated handling systems. Automatic transport of...

Open the catalog to page 10

Solutions for logistics and material handling vehicles Forklifts: Measuring the position of the fork Forklifts: Checking whether the seat is occupied Loading crane: Measuring the position of the hydraulic cylinders Automated Guided Vehicles (AGV): Monitoring driverless transport systems

Open the catalog to page 11

FORKLIFTS: MEASURING THE POSITION OF THE FORK With BML magnetic encoder systems In warehouses with less than ideal visibility, the fork position can be precisely determined. Our magnetic encoders are ideal for continuously detecting the depth position of the fork with millimeter accuracy. The magnetic tape recessed into the extendable part of the fork is sensed without contact by a receiver at the end of the fixed fork section. Good to know: When used on a forklift the driver can view any fork position on a display. FORKLIFTS: CHECKING WHETHER THE SEAT IS OCCUPIED With BES inductive sensors...

Open the catalog to page 12

Ensuring Trouble-Free Operation MUNICIPAL AND SPECIALTY VEHICLES When operating municipal vehicles it is especially important that the driver have a full range of safety equipment to ensure trouble-free operation. In many cases, sensors can be used like an eye, ear or sense of touch, becoming important aids in detecting hazards early. This will protect persons from injury and equipment from unnecessary damage.

Open the catalog to page 13

Solutions for Municipal and Specialty Vehicles Fire truck: Monitoring water pressure Fire truck: Checking tools for completeness Aircraft: Positioning the passenger stairs Bus: Monitoring the engine compartment cover

Open the catalog to page 14

FIRE TRUCK: MONITORING WATER PRESSURE With BSP pressure sensors AIRCRAFT: POSITIONING THE PASSENGER STAIRS With BUS ultrasonic sensors BUS: MONITORING THE ENGINE COMPARTMENT COVER With BES inductive sensors RFID systems provide security by determining if all tools are on board. All the tools that need to be present in the tool compartment are identified with a data carrier. A read/write head inside the vehicle detects the tools and sends their data to the central processor unit. And does it in real time, so the most up-to-date information is always available. RFID also provides the operator...

Open the catalog to page 15All Balluff GmbH catalogs and technical brochures

-

PRODUCTS FOR EFFICIENT AUTOMATION 5

656 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 4

190 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 3

584 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 2

444 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 1

796 Pages

-

PRODUCTS + NEWS

25 Pages

-

GUIDED CHANGEOVER SOLUTION

3 Pages

-

PRODUCTS FOR THE WASHDOWN AREAS

88 Pages

-

SOLUTIONS FOR DRIVE TECHNOLOGY

15 Pages

-

TAILOR-MADE QUALITY

5 Pages

-

WE MONITOR YOUR MACHINES

10 Pages

-

PACKAGING, FOOD AND BEVERAGE

76 Pages

-

MANAGING ALL YOUR DATA

6 Pages

-

MAGNETIC FIELD SENSORS

7 Pages

-

Balluff products and services

94 Pages

Archived catalogs

-

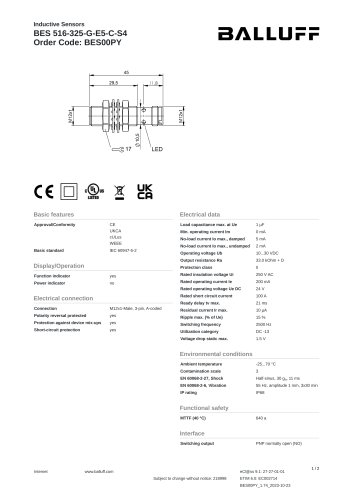

BES00PY

2 Pages

-

BES008L

2 Pages

-

BES02NC

2 Pages

-

BES01ZN

2 Pages

-

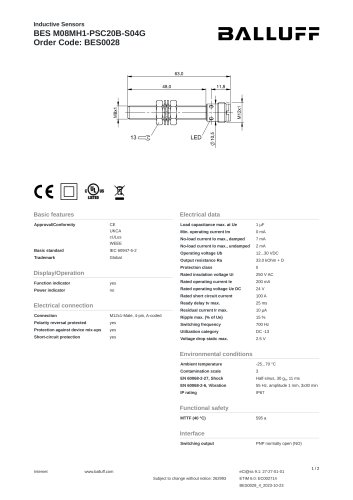

BES0028

2 Pages

-

BES05F9

2 Pages

-

BES054Z

2 Pages

-

BES0086

2 Pages

-

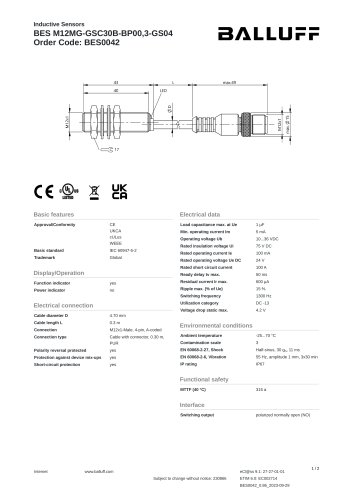

BES0042

2 Pages

-

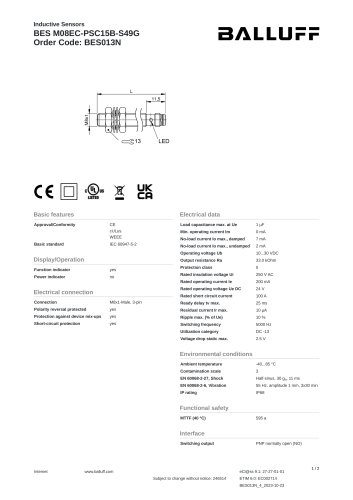

BES013N

2 Pages

-

BES00H4

2 Pages

-

BES003P

2 Pages

-

BES00HC

2 Pages

-

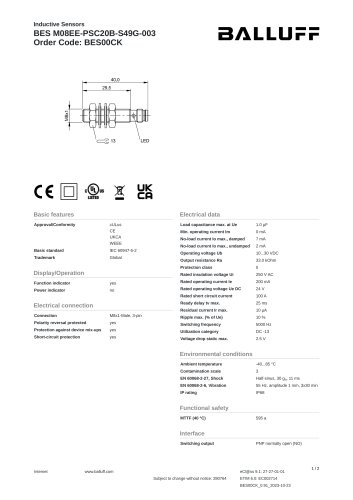

BES00CK

2 Pages

-

BES01ZW

2 Pages

-

BES00EF

2 Pages

-

BES00HF

2 Pages

-

BES00P7

2 Pages

-

BES0068

2 Pages

-

BES060T

2 Pages

-

QUALITY DOWN TO THE LAST DETAIL

94 Pages

-

OPENING NEW PERSPECTIVES

13 Pages

-

BALLUFF TEST CAMPUS

15 Pages