Website:

Balluff GmbH

Website:

Balluff GmbH

Group: Balluff

Catalog excerpts

HOW TO OPTIMIZE YOUR PROCESSES WITH INDUSTRIAL IDENTIFICATION

Open the catalog to page 1

CONTENTS 4 What traceability achives Lokaler Server 6 THE SIGNIFICANCE OF THE DATA SOURCES Datenverarbeitung in der Cloud oder vor Ort auf einem lokalen Server (On-Premise-Lösung) Intranet MQTT /AMQP EDGE GATEWAY zur Daten(vor)verarbeitung (optional) TOOL Beispiel: ROOM Fräsmaschine PLASTIC MOLDING Sensorik zur Objekterkennung – Track-and-trace-Anwendungen (siehe S. 7/8) How traceability works Tracking with switching and measuring sensors Track-and-trace with HF- and LF-RFID UHF-RFID offers multi-tagging Track-and-trace with optical identification Custom tailored: from the software to the...

Open the catalog to page 2

WHAT TRACEABILITY ACHIEVES Traceability is the ability to trace all processes in a production environment from raw material procurement to production to consumption and disposal. This has the goal of determining when and where a particular product was produced, how and by whom. This brings transparency to the production sequence, its framework, and the use of the (raw) materials. Traceability thus includes materials, products and workpieces in the creation process. It can also be extended to supplier chains. Two aspects are thus important for traceability: internal traceability within the...

Open the catalog to page 3

Data processing in the cloud or on-site on a local server (on-premises solution) Local server MQTT /AMQP The significance of the data sources Edge Gateway for data (pre-)processing (optional) Example: Milling machine Process and quality data suitable for tracking are often generated on the shop floor on the sensor/ actuator level. The sensors are an especially important part of the equation here. On this field level, data is generated which are used to uniquely identify materials, products and workpieces so that they can be individually labeled for a specific process. This tells you which...

Open the catalog to page 4

Simple queries for keeping the overview TRACKING WITH SWITCHING AND MEASURING SENSORS Simple tracking solutions can be implemented without great effort, because even simple switching and measuring sensors can be used for tracking. Since each of these sensors is connected to the controller, all the data automatically flow to this central point where they can be further processed. There in the controller, for example, a shift register can be used to create a representation of the system, assuming this is linked to other controllers and HMI solutions. By using many inductive sensors for...

Open the catalog to page 5

TRACK AND TRACE WITH HF- AND LF-RFID With HF (high frequency) or LF (low frequency) you can detect objects not only at close range, but also add information to them and use them for track-and-trace. This is made possible by a uniquely identifiable RFID data carrier which is fixed to the object and accompanies the object through the automated process. The information on the data carrier can be read out by the read/write head as the object transits the plant while any desired data can be written to the data carrier. This is reported by the read/write head to the controller or to the higher...

Open the catalog to page 6

For large detection ranges UHF-RFID OFFERS MULTI-TAGGING Unlike LF and HF systems used for track-and-trace at close range, UHF RFID technology offers a large working range and enables multi-tagging. Because UHF systems communicate over a range of up to 6 m and can read multiple data carriers simultaneously. In other words: UHF allows bulk reading. This makes UHF technology especially ideal for track-and-trace solutions in supply chain management and logistics. And UHF supports the digitalization of production and intralogistics processes. You can automatically register incoming and outgoing...

Open the catalog to page 7

Vision Solutions TRACK AND TRACE WITH OPTICAL IDENTIFICATION Along with RFID, track-and-trace can also be accomplished using optical solutions. Every object, whether a material or a tool, is uniquely marked with 1D and 2D codes and can be read using cameras, code readers or mobile handhelds. All the codes are permanently associated with the object, since they are glued on with a label, laser etched or otherwise printed or punched. This means every object can be uniquely identified. And this code information can be used in the warehouse or in production for example. It is also possible to...

Open the catalog to page 8

Create added value and be ready for the IIoT CUSTOM TAILORED: FROM THE SOFTWARE TO THE 360° IIOT SOLUTION Traceability projects related to the IIoT generally consist of sensors and Auto-ID. Also playing a key role is integration into the backend system of the user and thereby the software. Only custom tailored concepts will let you bundle and process all the data collected in the value creation chain to create added value. Taking your requirements as the starting point, we develop individual 360° IIoT solutions for which we evaluate the current situation, take your OT and IT infrastructure...

Open the catalog to page 9

ASSET TRACKING Asset tracking lets you track all the assets in a plant. From machine tools to molds and dies, modular automation sub-systems, workpiece carriers and containers or tanks and vessels that are among the most frequently tracked assets. All operating procedures are recorded to ensure consistent tracking. Now you know where, when and in what condition an asset was used. This gives you information about each individual asset, for example how long it was used, the setting parameters or maintenance intervals. TOOL ROOM This information enables predictive maintenance so that you can...

Open the catalog to page 10

Greater efficiency for the machinery TOOL-ID ENSURES OPTIMAL TOOL UTILIZATION Tool-ID from Balluff is simple to integrate and a highly effective solution for increasing the efficiency of your machinery. Tool-ID ensures optimal tool utilization. Tool-ID automatically detects all the tool parameters you have defined (tool number, tool diameter, tool length, number of cuts, ...), stores them directly on the tool or sends them to the controller. Tool-ID checks the current tool status, documents all the data and thereby enables a prognosis for future utilization. This is attractive for you as a...

Open the catalog to page 11All Balluff GmbH catalogs and technical brochures

-

PRODUCTS FOR EFFICIENT AUTOMATION 5

656 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 4

190 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 3

584 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 2

444 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 1

796 Pages

-

PRODUCTS + NEWS

25 Pages

-

GUIDED CHANGEOVER SOLUTION

3 Pages

-

PRODUCTS FOR THE WASHDOWN AREAS

88 Pages

-

MOBILE EQUIPMENT

21 Pages

-

SOLUTIONS FOR DRIVE TECHNOLOGY

15 Pages

-

TAILOR-MADE QUALITY

5 Pages

-

WE MONITOR YOUR MACHINES

10 Pages

-

PACKAGING, FOOD AND BEVERAGE

76 Pages

-

MANAGING ALL YOUR DATA

6 Pages

-

MAGNETIC FIELD SENSORS

7 Pages

-

Balluff products and services

94 Pages

Archived catalogs

-

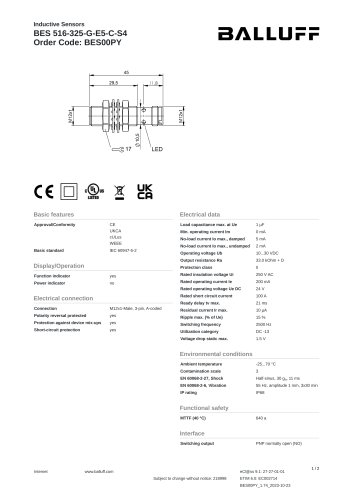

BES00PY

2 Pages

-

BES008L

2 Pages

-

BES02NC

2 Pages

-

BES01ZN

2 Pages

-

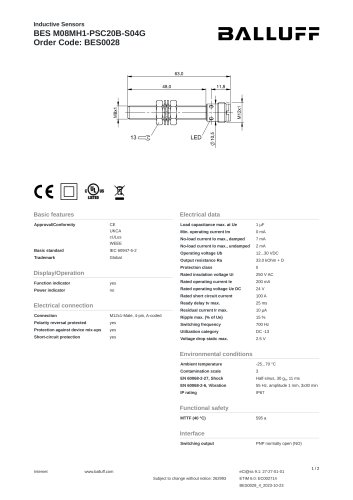

BES0028

2 Pages

-

BES05F9

2 Pages

-

BES054Z

2 Pages

-

BES0086

2 Pages

-

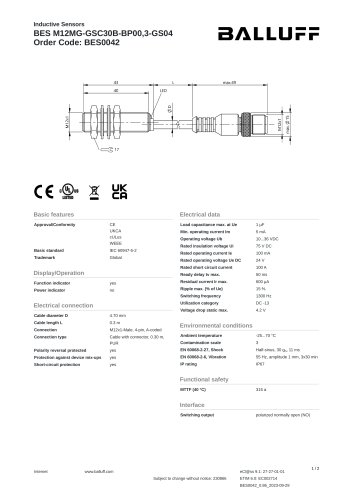

BES0042

2 Pages

-

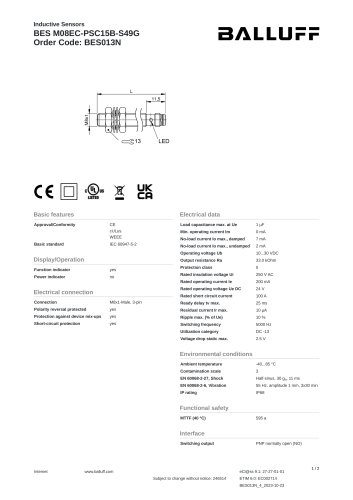

BES013N

2 Pages

-

BES00H4

2 Pages

-

BES003P

2 Pages

-

BES00HC

2 Pages

-

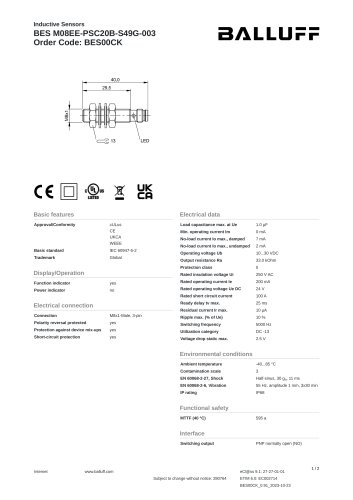

BES00CK

2 Pages

-

BES01ZW

2 Pages

-

BES00EF

2 Pages

-

BES00HF

2 Pages

-

BES00P7

2 Pages

-

BES0068

2 Pages

-

BES060T

2 Pages

-

QUALITY DOWN TO THE LAST DETAIL

94 Pages

-

OPENING NEW PERSPECTIVES

13 Pages

-

BALLUFF TEST CAMPUS

15 Pages