Website:

Balluff GmbH

Website:

Balluff GmbH

Group: Balluff

Catalog excerpts

Tire Industry HIGH PROCESS SECURITY AT EVERY STEP

Open the catalog to page 1

Balluff and the tire industry WE ARE AT HOME IN MANY DIFFERENT SECTORS

Open the catalog to page 2

Balluff and the tire industry HIGH PROCESS SECURITY AT EVERY STEP INTRALOGISTICS AND PROCESS MONITORING TIRE BUILDING As a partner of the automobile industry for many years Balluff offers vast automation know-how to provide optimal support in your tire manufacturing. Our expertise has been gained in practical applications and is based on solid development experience. We can draw from a wide range of sensors, systems and networking using many different technologies. For example, we can offer you length measuring systems for precise monitoring of closing movements on vulcanizing presses, or...

Open the catalog to page 3

CONTENTS Ensuring high tire quality 8 TIRE BUILDING Precision for every single step 14 VULCANIZATION Traceability guaranteed 20 INTRALOGISTICS AND PROCESS MONITORING GLOBAL PROJECT MANAGEMENT 32

Open the catalog to page 4

Tire building ENSURING HIGH TIRE QUALITY Ensure the high quality of your tires and the smoothest of processes in tire building. To make sure these critical process steps are accomplished optimally we provide you with sensors you can use to perfectly equip your tire building machine. For example, to exactly position your sliders, our various solutions offer you a number of options. At the same time you enhance process security, preventing downtimes and ensuring continuous material provision and consistently high process speed so that each tire blank is efficiently and correctly constructed.

Open the catalog to page 5

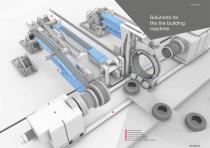

Solutions for the tire building machine Control the process Monitor material feed Position the slider exactly Ensure controlled movements Guarantee material availability Always keep an eye on operational status

Open the catalog to page 6

CONTROL THE PROCESS With BOD photoelectric distance sensors MONITOR MATERIAL FEED With BSI inclination sensors POSITION THE SLIDER EXACTLY With BTL magnetostrictive linear position sensors ENSURE CONTROLLED MOVEMENTS With BMF magnetic field sensors GUARANTEE MATERIAL AVAILABILITY With BUS ultrasonic sensors ALWAYS KEEP AN EYE ON OPERATIONAL STATUS With the BNI SmartLight stack lights Our photoelectric distance sensors monitor the liner sag to ensure correct material feed speed. By monitoring the process of tire building you are able to intervene in a timely fashion when problems arise. The...

Open the catalog to page 7

PRECISION FOR EVERY SINGLE STEP To ensure that the critical process of vulcanization of the green tire in the curing press runs properly, Balluff offers you optimal solutions for every single step. Each of these solutions contributes its part to process reliability. You get the highest precision in forming the green tire under high pressure and at high temperatures, whether you use our ultrasonic sensors for detecting the tires in the press, monitoring the pressure of the pneumatic lines using our pressure sensors, or ensuring controlled closing of the presses using our magnetostrictive...

Open the catalog to page 8

Solutions for the curing press Monitoring vulcanization pressure Simplify connections and start lowering costs Tire detection for process reliability Detect vulcanization progress at a glance Monitor position of the gripper arms Reliable closing movement

Open the catalog to page 9

MONITORING VULCANIZATION PRESSURE With BSP pressure sensors SIMPLIFY CONNECTIONS AND START LOWERING COSTS With BNI IO-Link valve interfaces TIRE DETECTION FOR PROCESS RELIABILITY With BUS ultrasonic sensors DETECT VULCANIZATION PROGRESS AT A GLANCE With BNI SmartLight stack lights MONITOR POSITION OF THE GRIPPER ARMS With BMP magnetic field positioning systems RELIABLE CLOSING MOVEMENT With BTL magnetostrictive linear position sensors Pressure sensors from Balluff ensure reliable pressure monitoring during vulcanization and thereby contribute to process reliability. Our solutions can be...

Open the catalog to page 10

Intralogistics and process monitoring TRACEABILITY GUARANTEED We use our identification solutions to accompany you reliably through the entire process chain: from delivery of the raw materials to production of the semi-finished products to tire manufacturing and beyond. Each tire can be uniquely identified and every process step traced. This uninterrupted documentation supports a reliable process and helps you meet the requirements for traceability. Our performance range includes industrial image processing, using SmartCameras, vision sensors and barcode readers. You also have access to...

Open the catalog to page 11

Semiconductor Industry | 23 Tire Solutions for intralogistics and process monitoring 2 Detect tires on the conveyor line Identify raw material Verify each production step Each manufacturing step is transparent Uniquely identify, ensure organized storage

Open the catalog to page 12

DETECT TIRES ON THE CONVEYOR LINE With BOS retroreflective sensors IDENTIFYING RAW MATERIAL With BVS HS-P handheld code readers and BNI RS232 converters VERIFY EACH PRODUCTION STEP With BVS SmartCameras EACH MANUFACTURING STEP IS TRANSPARENT With BIS industrial RFID systems UNIQUELY IDENTIFY, ENSURE ORGANIZED STORAGE With BIS industrial RFID systems Use our retroreflective sensors when removing the tire from the curing press after vulcanization without manual intervention. These sensors reliably detect whether there is another tire already on the conveyor just when one is being unloaded...

Open the catalog to page 13

INNOVATIVE SOLUTIONS FOR ALL REQUIREMENTS

Open the catalog to page 14

PRODUCT OVERVIEW Functions, interfaces and properties TIRE BUILDING Functions, interfaces and properties INTRALOGISTICS AND PROCESS MONITORING BOD photoelectric distance sensors Highly precise, stable measurements regardless of the surface, range 30…200 mm, rugged and compact housing, scalable measuring range Detect tires on the conveyor line Range 0…4 m, object detection regardless of its surface, color or material, also suitable for shiny objects, simple to align Monitor material feed High precision, continuous detection of rotary movements, space-saving with compact form factor, flexible...

Open the catalog to page 15

Balluff is one of the leading providers of high-quality sensor, identification, network and software solutions for your automation requirements. Family-run for more than 90 years, the company now employs more than 4000 employees in 38 subsidiaries with distribution, production and development sites worldwide, all working towards your success. Together with our branches, we guarantee the highest quality standards worldwide. This is how we empower you to always receive the best. We give our all to provide top services for innovative solutions that increase your competitive edge. Through years...

Open the catalog to page 16All Balluff GmbH catalogs and technical brochures

-

PRODUCTS FOR EFFICIENT AUTOMATION 5

656 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 4

190 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 3

584 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 2

444 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 1

796 Pages

-

PRODUCTS + NEWS

25 Pages

-

GUIDED CHANGEOVER SOLUTION

3 Pages

-

PRODUCTS FOR THE WASHDOWN AREAS

88 Pages

-

MOBILE EQUIPMENT

21 Pages

-

SOLUTIONS FOR DRIVE TECHNOLOGY

15 Pages

-

TAILOR-MADE QUALITY

5 Pages

-

WE MONITOR YOUR MACHINES

10 Pages

-

PACKAGING, FOOD AND BEVERAGE

76 Pages

-

MANAGING ALL YOUR DATA

6 Pages

-

MAGNETIC FIELD SENSORS

7 Pages

-

Balluff products and services

94 Pages

Archived catalogs

-

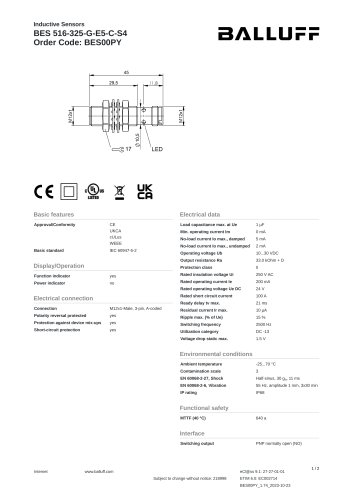

BES00PY

2 Pages

-

BES008L

2 Pages

-

BES02NC

2 Pages

-

BES01ZN

2 Pages

-

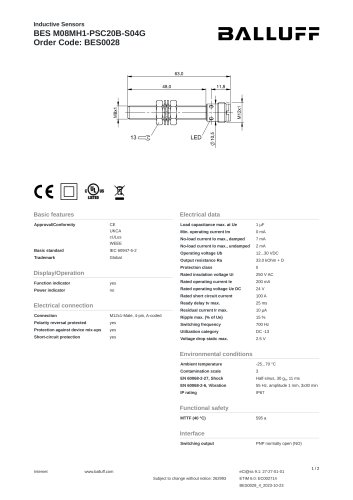

BES0028

2 Pages

-

BES05F9

2 Pages

-

BES054Z

2 Pages

-

BES0086

2 Pages

-

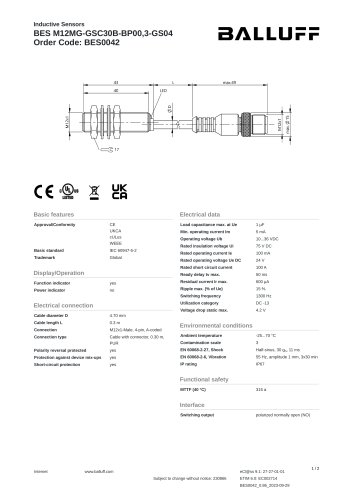

BES0042

2 Pages

-

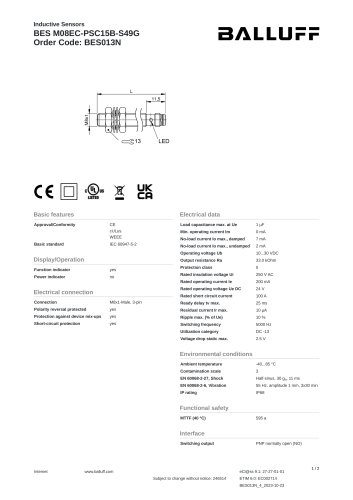

BES013N

2 Pages

-

BES00H4

2 Pages

-

BES003P

2 Pages

-

BES00HC

2 Pages

-

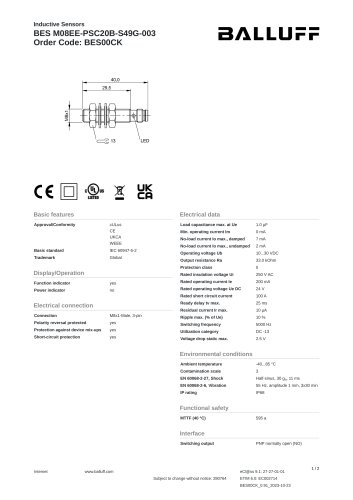

BES00CK

2 Pages

-

BES01ZW

2 Pages

-

BES00EF

2 Pages

-

BES00HF

2 Pages

-

BES00P7

2 Pages

-

BES0068

2 Pages

-

BES060T

2 Pages

-

QUALITY DOWN TO THE LAST DETAIL

94 Pages

-

OPENING NEW PERSPECTIVES

13 Pages

-

BALLUFF TEST CAMPUS

15 Pages