Website:

Balluff GmbH

Website:

Balluff GmbH

Group: Balluff

Catalog excerpts

BENCHMARKS FOR THE STANDARDS OF TOMORROW

Open the catalog to page 1

WE ARE AT HOME IN MANY DIFFERENT SECTORS

Open the catalog to page 2

8 Machining: Turning 12 Machining: Milling 16 Metal forming ECONOMICAL AND PRECISE – FROM SINGLE PARTS TO LARGE VOLUME Solutions for spindles, chucks, rotary and swivel tables Solutions for handling, transport and process monitoring Tool-ID solutions Tool management – regardless of frequency or environment Digital communication creates added value Universal, simple and flexible: IO-Link IO-Link saves time and money Safety over IO-Link FLEXIBLE RESPONSE TO CHANGING REQUIREMENTS 30 USING TOOLS EFFICIENTLY AND ALWAYS KNOWING WHAT IS HAPPENING 36 BENCHMARKS FOR THE STANDARDS OF TOMORROW

Open the catalog to page 3

ECONOMICAL AND PRECISE – FROM SINGLE PARTS TO LARGE VOLUME Machine tools are the backbone of modern manufacturing. They provide precision and high efficiency, and without them high-volume produced, high-quality products are impossible. As a longtime partner of the metalworking industry, we support you with a broad range of solutions. We have developed and produced these in close cooperation with innovation drivers in metalworking, and machine and systems providers. Whether in turning, milling or stamping, we have your particular requirements in constant view. Our solutions also ensure high...

Open the catalog to page 4

Machining: Turning 1 2 6 7 PROTECTION DEVICES MONITOR AND LOCK OUT With BID safety guard locking devices BAR LOADER MONITORING With BES inductive sensors Non-contact, transponder-coded safety interlocks are ideal for securing and monitoring guard doors and safety flaps to protect persons from potential hazards or the interruption of processes. The high coding level provides you with outstanding antitamper protection. Monitor feeding of the bar material using inductive sensors. Simply install multiple sensors at various locations. This permits you to achieve a seamless production process...

Open the catalog to page 5

TAILSTOCK POSITIONING With BTL magnetostrictive linear position sensors STEADY REST ALIGNMENT With BTL magnetostrictive linear position sensors CHECKING WORKPIECE CLAMPING With BIP inductive positioning systems DETECTING THE TURRET POSITION With BES inductive sensors MONITORING DRIVE BELTS With BCS capacitive or BES inductive sensors Our BTL magnetostrictive linear position sensors enable reliable and costeffective tailstock positioning, such as with a hydraulic or a simple motor-driven axis. A second measuring system can be installed for the fine-positioning. Steady rests assist the...

Open the catalog to page 6

MONITORING END POSITIONS With BES inductive sensors MONITORING TOOL CLAMPING With BIP inductive positioning systems Do you need to monitor the traverse path of machine axes? You can choose from various options: Standard option with BNS mechanical position switches according to the principle of normally closed contacts connected in series, or non-contact with inductive sensors. If you use an incremental linear magnetic encoder system, the sensor signals can also be used for the reference point move. Our inductive position sensors provide information about the correct clamping of the tool:...

Open the catalog to page 7

DECENTRALIZING INSTALLATION TECHNOLOGY With BNI network modules SAFE COMMUNICATION With BNI Safety over IO-Link blocks DETECTING THE ROTATION ANGLE ON THE C-AXIS With BML magnetic encoders IDENTIFYING TOOLS IN THE MAGAZINE With BIS Industrial RFID systems CORRECTLY ASSOCIATE AND TRACK WORKPIECES With BIS Industrial RFID systems DISPLAYING OPERATING STATUS With SmartLight LED stack lights Compared with traditional star topologies, fieldbus blocks make the startup of the machine controller much simpler and cost-effective. Designed for all commonly used fieldbus systems, these blocks enable...

Open the catalog to page 8

Metal forming 2 Mechanical presses have become indispensable tools for metal forming. The tools used, which are of particularly high quality and precision, are most often designed for high production quantities. And no one can afford long downtimes because every minute is valuable and any lengthy production delay costs a lot of money. Especially if you discover that your expensive assets have been damaged and need to be replaced. Sensor solutions are ideal for precise press position during the stamping process. They allow malfunctions to be immediately detected and consequential damage...

Open the catalog to page 9

CONTROLLING HYDRAULIC PRESSES With BTL magnetostrictive linear position sensors CHANGING DIE SETS With BIC inductive couplers MONITORING SHEET METAL THICKNESSES With BAW inductive distance sensors CHECKING METAL STRIP SAG With BUS ultrasonic sensors MONITORING PRESS FORCES With BSP pressure sensors Hydraulic presses (long strokes, low stroke counts) achieve their rated force over the entire stroke travel. Magnetostrictive linear position sensors handle position monitoring. The magnetic position marker is attached to the slide or ram, and the rod with the measuring element is fixed to a...

Open the catalog to page 10

Optimizing automation and assemblies FLEXIBLE RESPONSE TO CHANGING REQUIREMENTS Balluff has been a partner of the metalworking industry since the 1950s and helped to shape the world of machine tool building: from the classic manually operated machines to the complex, automated multi-axis machining centers of today. We are one of the pioneers in the development of inductive sensors; more than 30 years ago we were the very first to turn this technology into RFID for tool identification. We continue to expand our complete offering for metalworking and machine tool building. In addition to...

Open the catalog to page 11

Solutions for spindles, chucks, rotary and swivel tables Turning Produce reliably and with precision – from single parts to high volume SAFETY FOR CLAMPING FIXTURES With BNI galvanically isolated sensor/ actuator hubs SENDING SIGNALS AND DATA ON SWIVEL TABLES With BIC inductive couplers Our galvanically isolated sensor/actuator hubs ensure safety on the clamping fixture of the pneumatic workpiece holder. These IO-Link modules for safety applications permit applications up to PLd/SIL2 and are equally suited for connecting commonly available binary sensors and actuators. If you want to...

Open the catalog to page 12All Balluff GmbH catalogs and technical brochures

-

PRODUCTS FOR EFFICIENT AUTOMATION 5

656 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 4

190 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 3

584 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 2

444 Pages

-

PRODUCTS FOR EFFICIENT AUTOMATION 1

796 Pages

-

PRODUCTS + NEWS

25 Pages

-

GUIDED CHANGEOVER SOLUTION

3 Pages

-

PRODUCTS FOR THE WASHDOWN AREAS

88 Pages

-

MOBILE EQUIPMENT

21 Pages

-

SOLUTIONS FOR DRIVE TECHNOLOGY

15 Pages

-

TAILOR-MADE QUALITY

5 Pages

-

WE MONITOR YOUR MACHINES

10 Pages

-

PACKAGING, FOOD AND BEVERAGE

76 Pages

-

MANAGING ALL YOUR DATA

6 Pages

-

MAGNETIC FIELD SENSORS

7 Pages

-

Balluff products and services

94 Pages

Archived catalogs

-

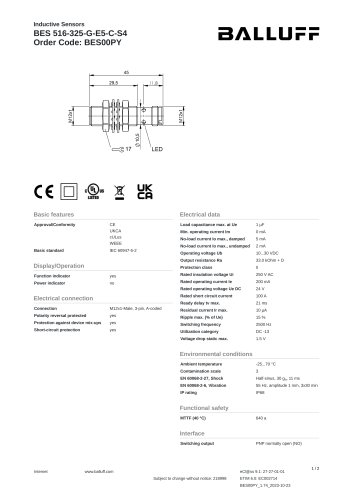

BES00PY

2 Pages

-

BES008L

2 Pages

-

BES02NC

2 Pages

-

BES01ZN

2 Pages

-

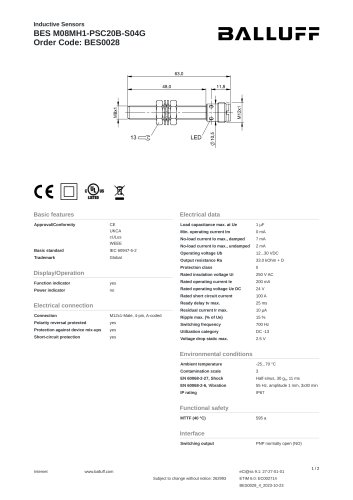

BES0028

2 Pages

-

BES05F9

2 Pages

-

BES054Z

2 Pages

-

BES0086

2 Pages

-

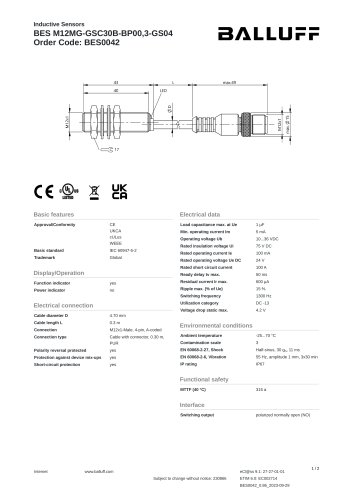

BES0042

2 Pages

-

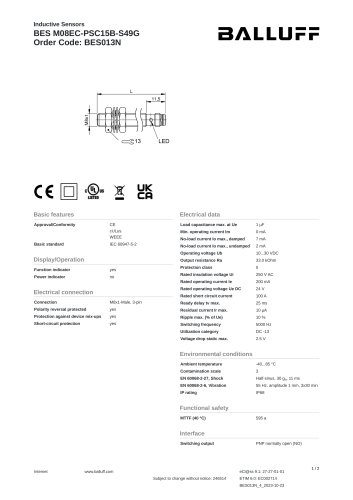

BES013N

2 Pages

-

BES00H4

2 Pages

-

BES003P

2 Pages

-

BES00HC

2 Pages

-

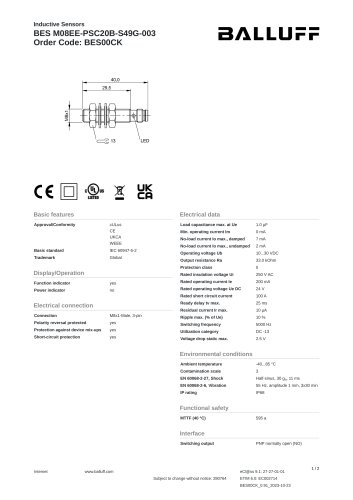

BES00CK

2 Pages

-

BES01ZW

2 Pages

-

BES00EF

2 Pages

-

BES00HF

2 Pages

-

BES00P7

2 Pages

-

BES0068

2 Pages

-

BES060T

2 Pages

-

QUALITY DOWN TO THE LAST DETAIL

94 Pages

-

OPENING NEW PERSPECTIVES

13 Pages

-

BALLUFF TEST CAMPUS

15 Pages