Catalog excerpts

Explosion Proof

Open the catalog to page 1

Why Baldor? Industry’s shortest lead times/Flexible manufacturing. Baldor has the industry’s shortest lead times on custom motors – just ten working days. Our unique LEAN FLEX FLOW™ manufacturing process lets us produce any order in any quantity, quickly and efficiently. For nearly 100 years, Baldor has strived to provide customers with the best value and reliability in industrial electric motors. That dedication shows in customer preference for Baldor•Reliance motors. To be considered as the most preferred... Baldor offers the industry’s broadest line of stock products. Save valuable time...

Open the catalog to page 2

Explosion Proof Motors Since the 1940s, when Baldor introduced its first explosion-proof motor, the company has designed and manufactured motors that meet or exceed industry standards, ensuring safety, energy efficiency and overall reliability. When you specify a Baldor explosion-proof motor, you can trust that it meets your specifications, and more. Baldor follows the specs to the letter, and then takes it a step further. We listen to motor users and learn from their experiences. We design and build motors that deliver reliable performance. And we earn long-term customer relationships by...

Open the catalog to page 3

Making Energy Efficiency Work For You Why is Energy Efficiency Important? Electric motor-driven systems used in industrial processes consume 63% of all electricity used in U.S. industrial sector according to a U.S. Department of Energy report published in 1998. A 2002 report shows that companies that practiced DOE “best practices” actually averaged 33 percent savings if they were to apply motor and motor system efficiency upgrades, including the use of adjustable speed drives. The potential positive impacts on companies’ bottom lines and the environment are significant. Purchase Price is...

Open the catalog to page 4

Baldor Division 1, Explosion Proof Motor Capabilities – 1/4 Hp to 800 Hp NEMA Frame Size Capability Division 1 enclosures: available as Class 1, Group C&D and Class II, Groups F&G in all sizes. Class I, Group D and Class II, Groups E,F&G are available in Cast Iron frames 182T and larger. Single Phase – 1/4 to 5HP ( 48 to 215T frame), Three Phase – 1/4 to 300HP (48 to 449 frame) Hp 0.25 0.33 0.50 0.75 1 1.5 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125 150 200 250 300 Above NEMA Frame Capabilities All Large AC Division 1 motors have the following specifications: TEFC Enclosure, 1.0 service...

Open the catalog to page 5

Baldor Explosion Proof Motors for the North American Marketplace In the North American marketplace, Baldor uses Underwriters Laboratories (U.L.) and the Canadian Standards Association (CSA) as certifying bodies to approve and label our electric motors for use in Division based hazardous locations per NFPA70 National Electric Code (NEC) and C22.1, the Canadian Electric Code. Baldor explosion proof motors may be marked with one or more of the following: UL Listing mark for use in the United States. Products with this mark have been evaluated to U.S. safety requirements. CSA Listing mark for...

Open the catalog to page 6

Baldor Division 1, Class & Group Stock ratings All Baldor Division 1, stock motor ratings will have a red circle symbol next to the catalog # that indicates the explosion proof Class and Group the motor is certified to meet. XP Class & Group Symbol Class 1, Group D, Class 2, Group F & G Class 1, Group D, Class 2, Group E, F & G Class 1, Group C & D, Class 2, Group F & G Thermal Protection As required by UL and CSA, explosion proof motors with Class II, Group F&G approvals must have over temperature protection. Internally mounted automatic thermal overloads (ATO’s) are used on motors 1.5hp...

Open the catalog to page 7

Baldor Custom Explosion Proof Motors for Outside North America Baldor offers a wide variety of Custom Explosion Proof motors for use outside the US market where IEC based standards of certification are required. Europe - ATEX Directive IEC standards that have been adopted by countries in Europe are known as European Norms (EN). Directives (Laws) are issued by the European Union (EU) based on these EN standards. Equipment tested to EN standards bears a CE mark. The CE mark is a mandatory conformity mark for products placed on the market in the European Union. With the CE marking on a...

Open the catalog to page 8

Baldor Custom ATEX Capabilities Matrix - Group II (Surface Industry Applications) Explosion Protection Apparatus Group Temp Code ExnA (Non-Sparking) Zone 2 Extb (Dust Ignition Proof ) IIC Zone 21 IIIA, IIIB & IIIC Explosive Dust Environments (D) Baldor motors marked “Extb” for Zone 21 may be additionally labeled “suitable for Zone 22 (EPL Dc)” Dual Protection Gas & Dust Environments (G/D) Increased Safety Baldor ATEX motors can be dual labeled for “Exd” (Flameproof) and “Extb” (Dust Ignition Proof), Zones 1, 21 to meet the most hazardous explosive atmosphere applications. “Exd” motors...

Open the catalog to page 9

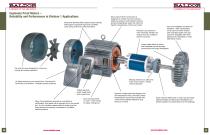

Explosion Proof Motors – Reliability and Performance in Division 1 Applications Brass and Stainless Name plates clearly indicate listing agency approval logos and complete class, group and temp code information Heavy Duty Frame construction is designed to contain maximum internal explosion pressure and maintain external surface temperatures below the minimum ingintion temperature of the environment Precision cast aluminum rotor minimizes vibration for long service life. Coated to prevent corrosion Cast iron endplates and fancover standard – 250T-up (standard on all cast iron frame motors)...

Open the catalog to page 10

Single Phase and Three Phase Explosion-Proof Motors with Rigid Base These motors are ideal for a wide variety of applications where hazardous fumes or dust may be present. Available from stock in 1/4 hp though 300 hp, in NEMA frames 48 through 449T. U.L. and CSA approved for Division 1, Class I, Group D; Class I, GroupD, Class II, Group F & G; Class I, Group C& D, Class II, Group F & G. 1.0 Service Factor. Performance Data, Single Phase, Foot Mounted Hp Amps @ High V Full XP XP Catalog Load Cls & Temp Full Locked Number Torque Grp Code Load Rotor Lb. Ft. Power Factor % Full Full 1/2 3/4 3/4...

Open the catalog to page 11All Baldor Electric Company catalogs and technical brochures

-

D-Flex

2 Pages

-

PT Components Engineering Catalog

801 Pages

-

Lagging For pulleys

8 Pages

-

Baldor-Reliance® DC Drive

4 Pages

-

P-Base Motors

2 Pages

-

Fire Pump Motors

4 Pages

-

Baldor-Reliance® Food Safe

8 Pages

-

CA501

28 Pages

-

2020 Baldor-Reliance® 501

390 Pages

-

HDS high-performance AC

44 Pages

-

Raptor coupling (metric)

28 Pages

-

Maxum XTR

100 Pages

-

AC Servo Motors BSM Series View All

100 Pages

-

HT500 synchronous drive system

116 Pages

-

Tigear 2 Family

228 Pages

-

RPM III IEC Integral HP DC Motors

132 Pages

-

Large Frame AC Induction Motors

55 Pages

-

European Stock Product Catalog

116 Pages

-

Dodge SNX & SDX

4 Pages

-

Stainless Steel Motors

4 Pages

-

Hermetic Motors

1 Pages

-

Immersible Motors

2 Pages

-

Submersible Motors

2 Pages

-

API 541 Large AC Motors

2 Pages

-

Cooling Tower Motors

2 Pages

-

Large AC Motors

48 Pages

-

Severe Duty Motors

48 Pages

-

Custom Motors

4 Pages

-

IEC Motors

16 Pages

-

VS1ST Inverter

4 Pages

-

VS1MX Inverter

4 Pages

-

Drives Overview

32 Pages

-

SleeveOil Bearing

4 Pages

-

ISN Bearings

8 Pages

-

Imperial Bearings

8 Pages

-

Grip Tight

8 Pages

-

Setscrew Mount Bearings

8 Pages

-

To be the Best

16 Pages

-

Torque Arm-II

6 Pages

-

Quantis Gearmotors & Reducers

12 Pages

-

Pump Couplings

4 Pages

-

D Flex couplings

2 Pages

-

Grid Lign Couplings

2 Pages

-

Gear Couplings

2 Pages

-

Grip Tight Bushing

2 Pages

-

Poly Disc Couplings

2 Pages

-

Para-Flex G-Series Couplings

12 Pages

-

Real-Time Ethernet Solutions

48 Pages

-

AC Servo Motors and Gearheads

128 Pages

-

Motion Solutions

20 Pages

-

Company Profile

2 Pages

Archived catalogs

-

Baldor - General Product Catalog

16 Pages

-

Linear Motors and Stages

48 Pages

-

AC Servo Drives

32 Pages