Catalog excerpts

Cement Mortar Lining Winch decreased labour cost decreased cement mortar consumption decreased waste removal cost increased site efficiency increased lining rate increased work safety When applying a conventional method of internal cement motor lining in a drinking water mains, you have to put up with the following drawbacks: High preparatory effort before lining, high labour cost incurred by laying out hoses during lining and high cleaning and clearing effort after lining, unless you decided to use a Bagela cement mortar lining winch. The Bagela cement mortar-lining winch is self-propelled and may be manoeuvred independently over the working pit. The cement mortar feeding hose, the compressed-air hose and the pulling rope are bound into a bundle, which is neatly stacked on the reel. While the hose bundle is brought into the pipe to be lined, the supply lines may be connected to the swivel inlets. After a test run of the spinning head, lining operation may be started immediately. During the lining process, for which only two operators are needed, i.e. one at the winch and one at the cement mixer, the rope of a second winch may already be brought into the next pipe section. The speed at which the spinning head is to be pulled through the pipe may be preset at the proportional control with its target and actual data line-up and may be kept absolutely constant, irrespective of the number of hose layers stacked on the drum. The operating data, i.e. lining advance, pulling speed and pulling force are displayed in digital notation and recorded in a lining log. Specifications are subject without notice. Output details are depending on use conditions.

Open the catalog to page 1

Cement Mortar Lining Winch In conventional lining methods, laying out of hoses poses a number 1. A lot of space is needed. Laid out hoses of 100 m length, for example, with a sufficient large diameter require not only space, which is especially rare in built-up areas, but may also be a hazard to the traffic. 2. During hot summer days there is always the risk of the spinning head getting blocked with the hoses lying on the Moreover, the hose drum is equipped with a water spray jet, which keeps the mortar hose cool at high ambient 3. Laying out the hoses on the dirty pavement stands in direct...

Open the catalog to page 2All Bagela Baumaschinen GmbH & Co. KG catalogs and technical brochures

-

Asphalt-Recycler

6 Pages

-

Pipe-renewal

14 Pages

-

Blow-In Systems

20 Pages

-

Trailers

24 Pages

-

Winches

18 Pages

-

RBH40-63

1 Pages

-

Pipe Laying

2 Pages

-

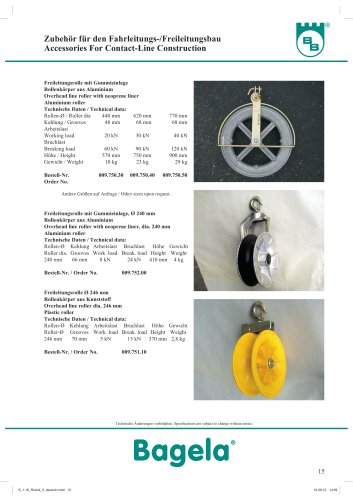

Deflection booms and rollers

2 Pages

-

Duct brushes

1 Pages

-

Pipe Cleaning

2 Pages

-

Accessories

1 Pages

-

Calibration accessories

4 Pages

-

Cable Pulling grips

4 Pages

-

Length measuring devices

2 Pages

-

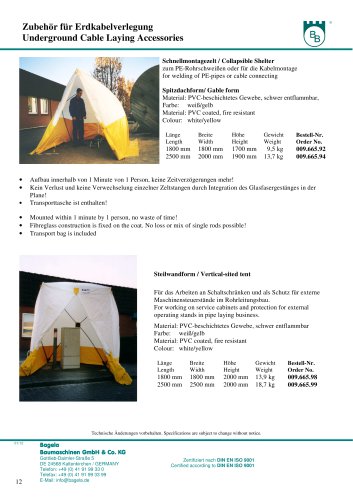

Tents and screens

2 Pages

-

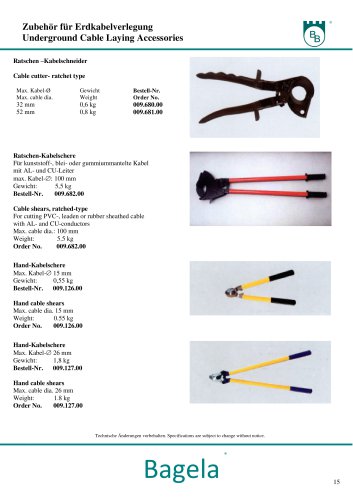

Cable and pipe cutter

2 Pages

-

Manhole cover lifter

2 Pages

-

Stringing gun EZ 100

2 Pages

-

Cable protection rollers

2 Pages

-

Cable protection bends

2 Pages

-

Glass fibre rods

3 Pages

-

Cable drum transport devices

1 Pages

-

Lifting jacks

5 Pages

-

Cable rollers

4 Pages

-

CPC

2 Pages

-

BA 7000F, BA 10000F

2 Pages

-

BA 4000

2 Pages

-

Microflow

2 Pages

-

Miniflow

2 Pages

-

Multiflow

3 Pages

-

Powerflow

3 Pages

-

BKS 1200

2 Pages

-

BKS 800

2 Pages

-

BKS 400

2 Pages

-

Tube coil reels

1 Pages

-

BRT 20

1 Pages

-

BRVT 17

1 Pages

-

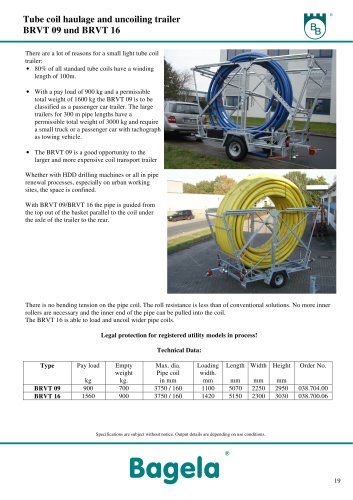

BRVT 09 and BRVT 16

1 Pages

-

BRT 65

2 Pages

-

BRT 25 - BRT 50

2 Pages

-

BTT 130.80V bis BTT 201.10V

2 Pages

-

BKT 18 up to BKT 80

3 Pages

-

RWF 1500

1 Pages

-

KW 3F and KW 4F

1 Pages

-

Reconstruction Technologies

2 Pages

-

RW 1500

1 Pages

-

RW 3000 - RW 4000 - RW 5000

2 Pages

-

Mounted Winches

2 Pages

-

softliner winch type RW 1500

1 Pages

-

W 2500 / W 3000

2 Pages

-

30/11 - 50/03

1 Pages

-

KW 1002 - KW 2002 - KW 3002

2 Pages

-

KTW 500 / KTW 1005

1 Pages

-

BTT 100.80 and BTT 160.20

1 Pages

Archived catalogs

-

RKW 3 - RKW 4 - RKW 5

2 Pages

-

KTW 1000

1 Pages